Automatic agent weighing device

A weighing device and medicine weighing technology, applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problems of low dosage control, low weighing efficiency, low weighing accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

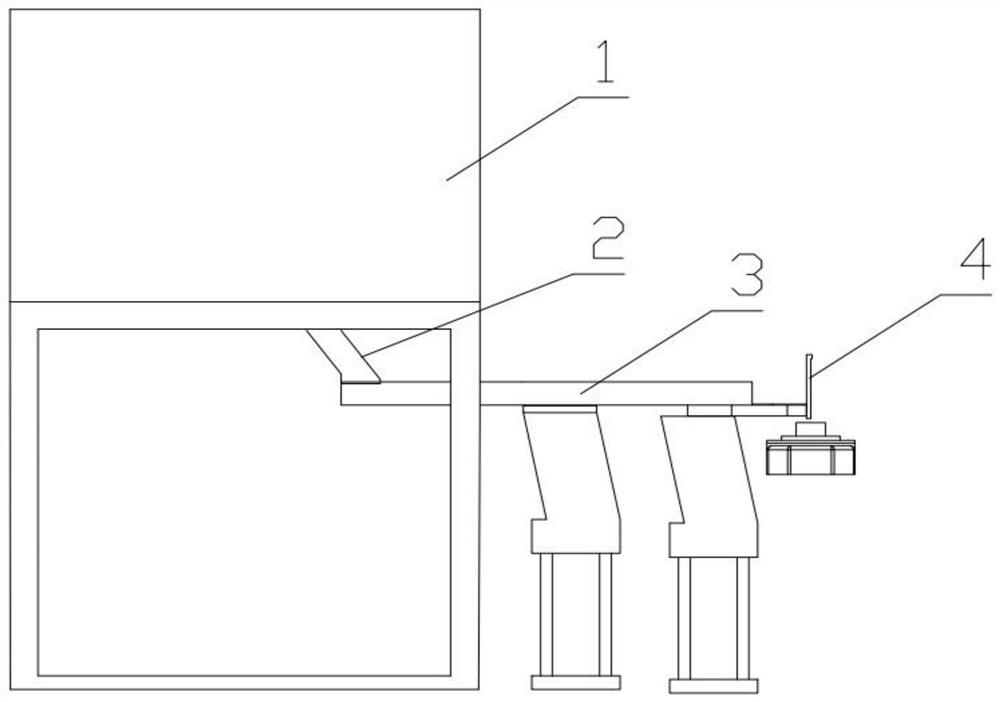

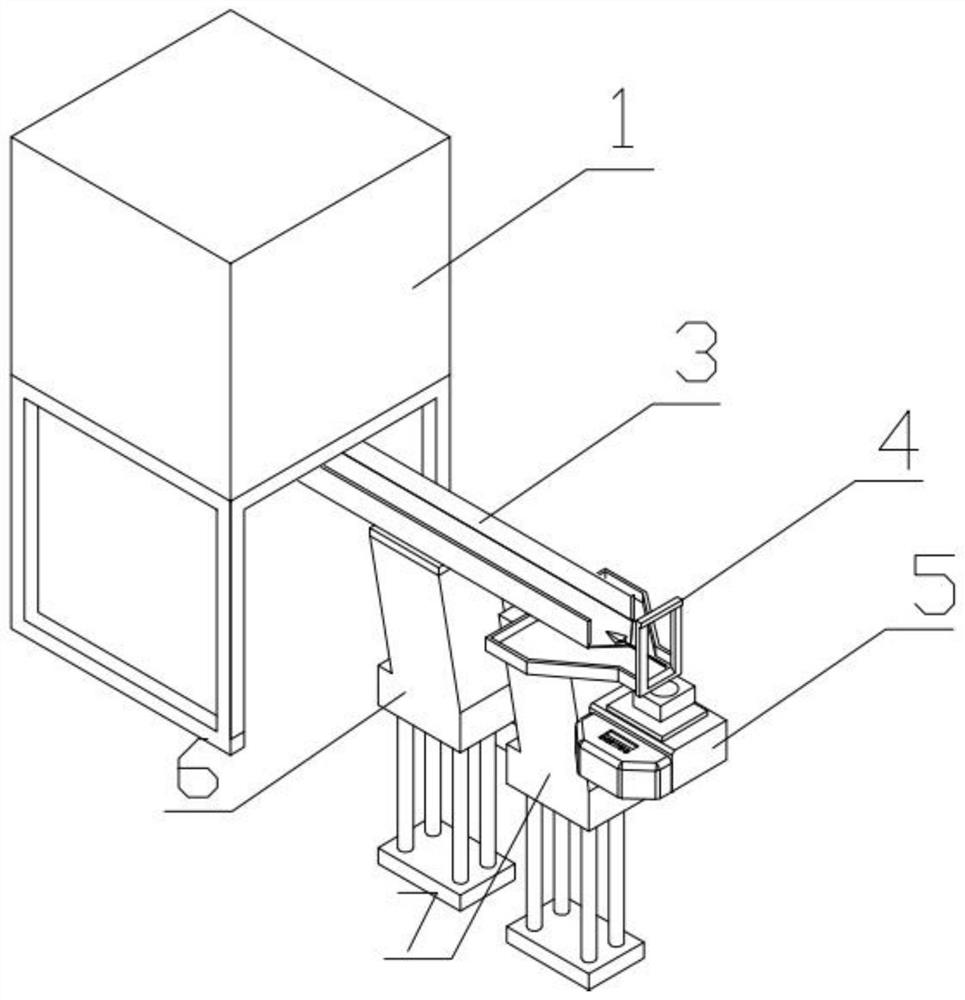

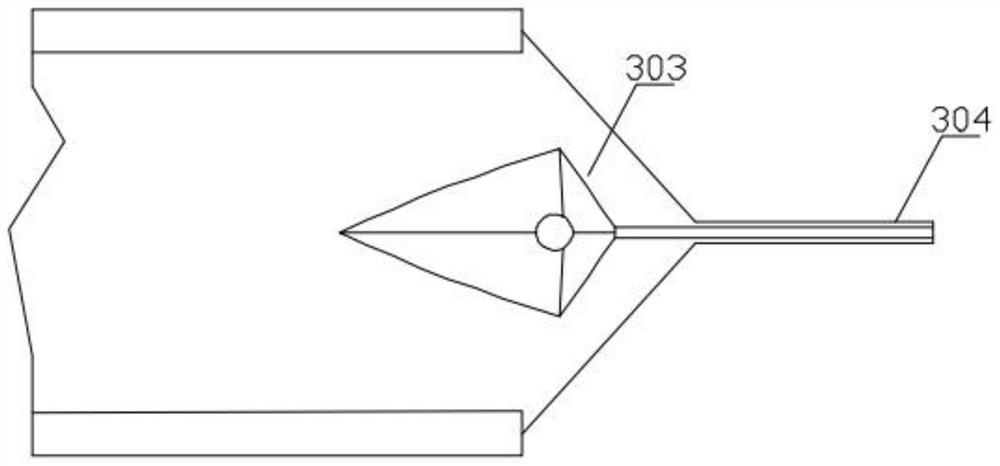

[0029] like figure 1 and figure 2 As shown, an automatic medicine weighing device includes a medicine filling box 1, a medicine pouring slide 2, a medicine weighing channel 3, a baffle plate 4 and a weighing device 5. and if Figure 4 and Figure 5 As shown, the weighing channel 3 includes a common weighing channel 301 , a coarse weighing channel 302 and a fine weighing channel 304 .

[0030] The medicine pouring chute 2 is installed on the bottom of the charge box 1, and the bottom of the medicine pouring chute 2 is connected to the front end of the common weighing channel 301. The top of the drug pouring chute 2 is provided with a shutter (not shown in the figure), and there is a gap extending horizontally between the shutter and the drug pouring chute 2. The width of the gap matches the medicament, and the medicament can only pass through the gap Flow into the medicine pouring slideway 2 from the medicine filling box 1 to ensure that only one layer of medicine passes t...

Embodiment 2

[0040] like Image 6 and Figure 7 As shown, the difference between this embodiment and Embodiment 1 is that the baffle plate 4 includes a left baffle plate 401 and a right baffle plate 402, and under the control of a cylinder or other control devices, the left baffle plate 401 and the right baffle plate 402 move horizontally, It is used to control the opening or blocking of the end of the coarse weighing channel 302 .

[0041] like Image 6 As shown, during rough weighing, the left baffle plate 401 and the right baffle plate 402 move away from each other, and there is a gap between the left baffle plate 401 and the right baffle plate 402, so that the end of the coarse weighing channel 302 is opened. At this time, both the precise weighing vibrator 6 and the coarse weighing vibrator 7 vibrate rapidly, the coarse weighing channel 302 is used as the main discharge port, and the fine weighing channel 304 is used as the secondary discharge port, so that a large amount of medicam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com