Construction method of tower type working condition crawler crane for pole bending or pole lifting without removing steel wire rope of hook head

A construction method and crawler crane technology, which are applied in the directions of load hanging components, transportation and packaging, can solve the problems of economic loss, time-consuming and laborious removal of wire ropes, and easy crushing of wire ropes, etc. The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

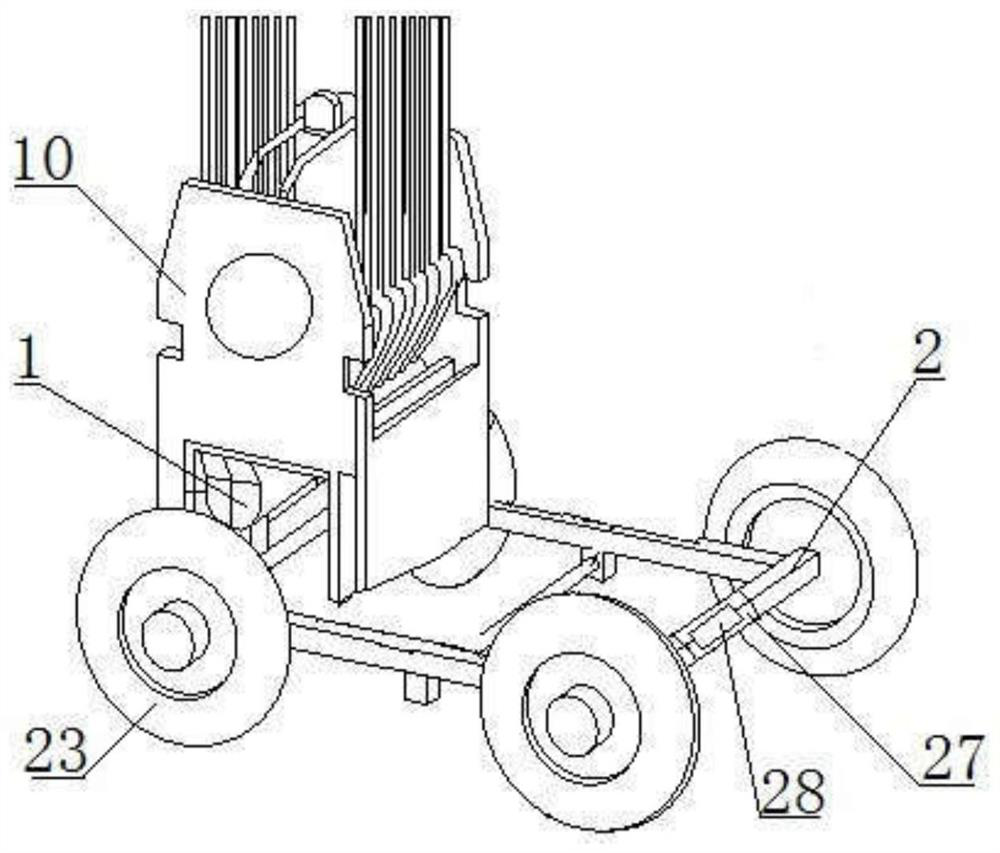

[0024] Such as Figure 1 to Figure 4 As shown in the figure, a construction method for avoiding dismantling the wire rope of the hook head when the crawler hangs the sprawling pole or the pole in the tower working condition includes the following steps:

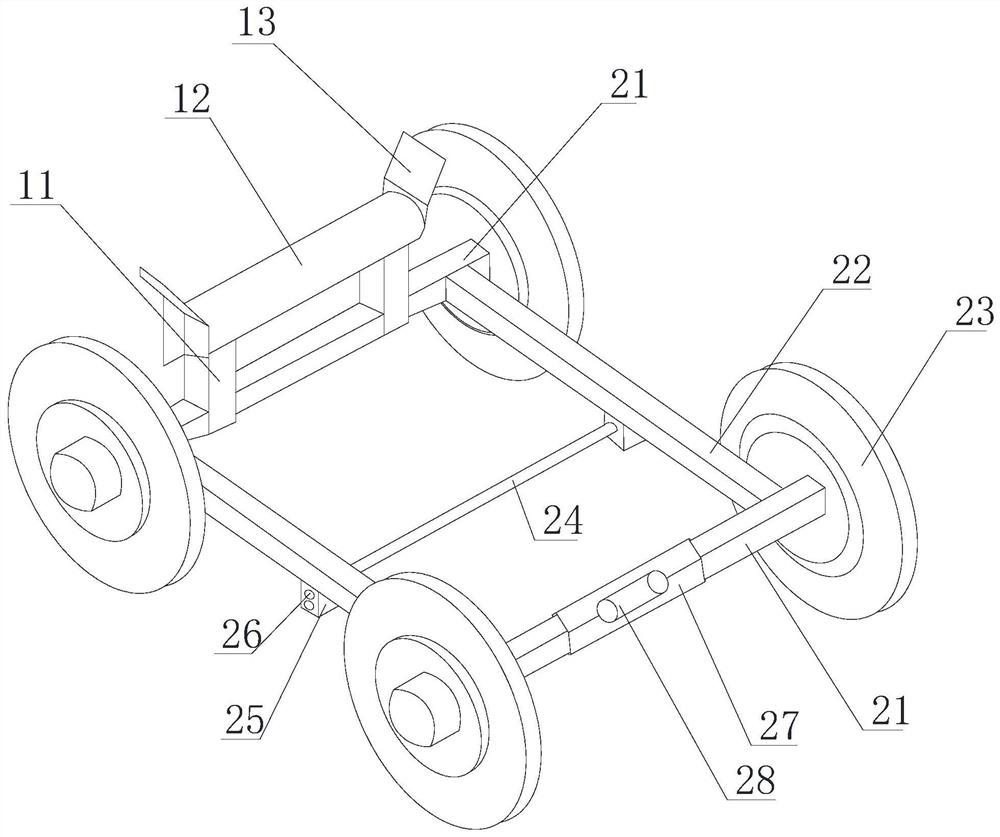

[0025] S100, making the support frame 1 and the mobile trolley 2, and setting the support frame 1 on the rear side of the mobile trolley 2 to form a movable support;

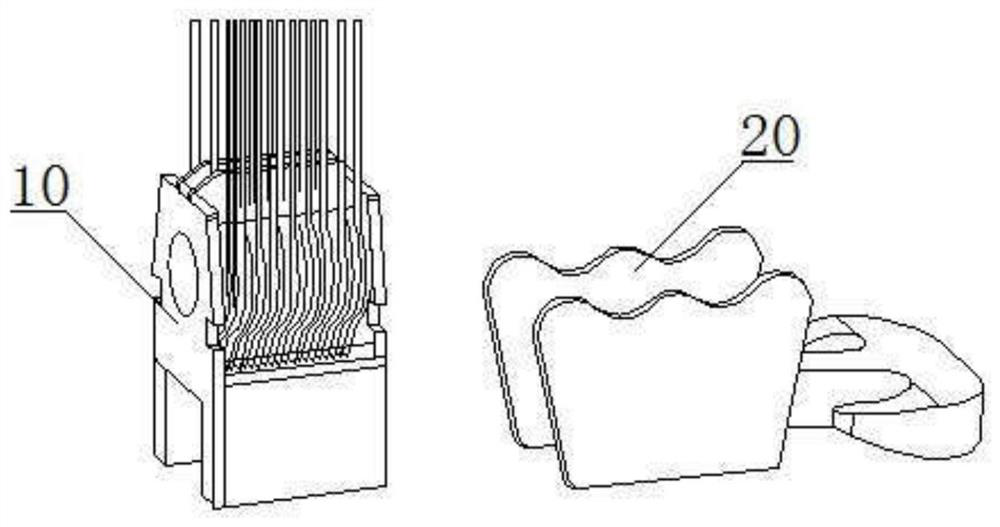

[0026] S200. In the crawler crane in the tower working condition, disassemble the hook head 20 from the combin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com