Railway gantry crane lifting appliance positioning control system and method

A technology of positioning control and gantry crane, which is applied in the directions of transportation and packaging, load hanging components, safety devices, etc. It can solve problems affecting work efficiency and reduce loading and unloading speed, so as to improve production efficiency, prevent hoisting, and eliminate potential safety hazards Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

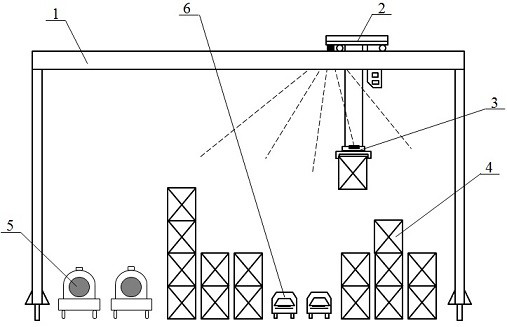

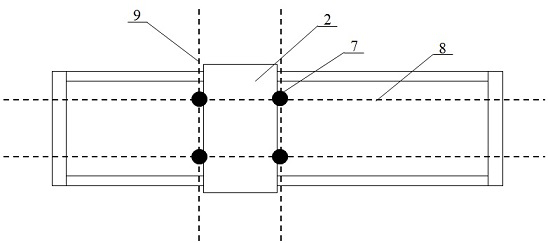

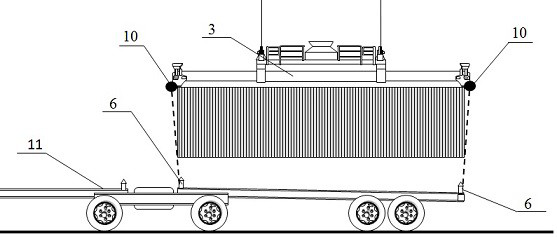

[0018] The laser scanner (7) is installed on the crane trolley (2), there are multiple laser scanners (7), and one or more laser scanners (7) are installed in the front and rear directions of the trolley (2) , the scanning direction is parallel to the horizontal stacking direction of the containers, and the laser scanning measures the position of the trolley (2), the lifting height of the spreader (3), the container (4) on the yard and the gantry crane (1) getting off the train (5), the weight The distribution position and stacking height of container trucks (6); another or more laser scanners (7) are installed in the left and right directions of the trolley (2), and the scanning direction is perpendicular to the horizontal stacking direction of containers, and the adjacent rows of containers are scanned. Positioning measurement to prevent collision with adjacent containers during lifting.

[0019] The multiple laser scanners (7) are connected to the controller, and the contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com