Container posture detection device and method

A detection device and container technology, applied in measurement devices, optical devices, radio wave measurement systems, etc., can solve problems such as increased loading and unloading time, safety accidents, and automatic loading and unloading failures, and achieve the effect of improving loading and unloading efficiency and preventing lifting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further elaborated below by describing a preferred specific embodiment in detail in conjunction with the accompanying drawings.

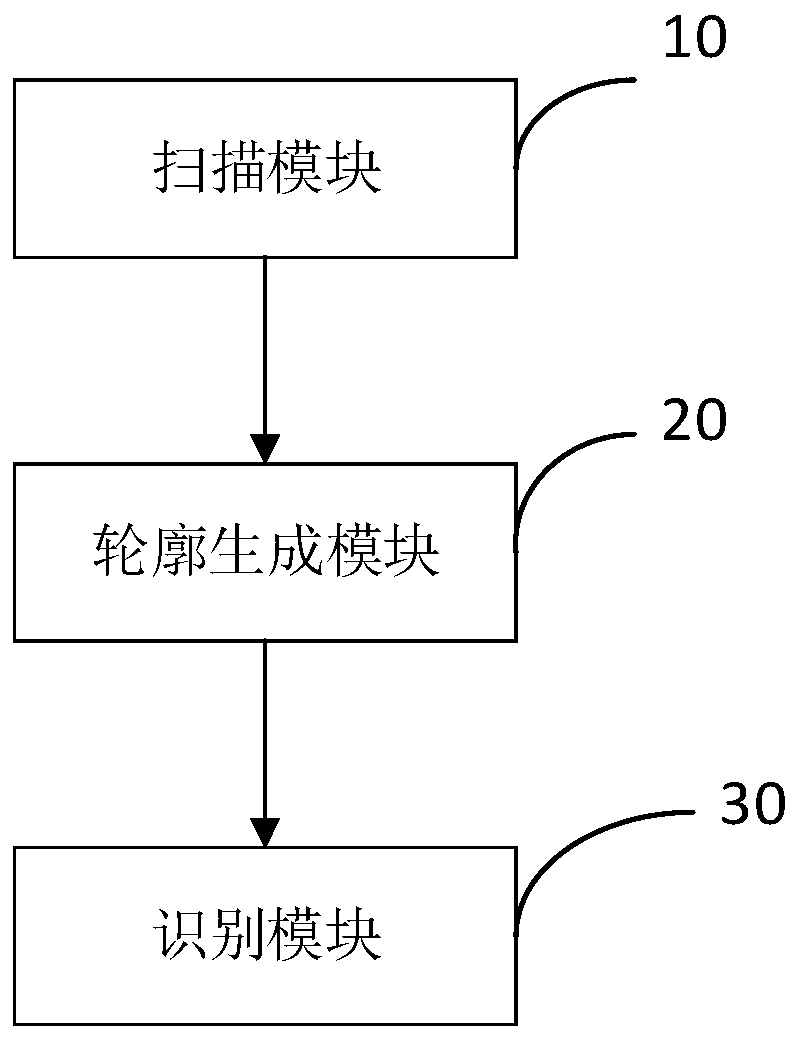

[0034] Such as figure 1 As shown, a container posture detection device includes: a scanning module 10, which is used to scan the container trucks passing through the buffer zone in real time, to obtain the vehicle contour point data of each scanning section; a contour generation module 20, which is used to The vehicle contour point data of the scanning section generates a three-dimensional contour of the vehicle; the recognition module 30 is configured to recognize the change of container attitude according to the three-dimensional contour of the vehicle.

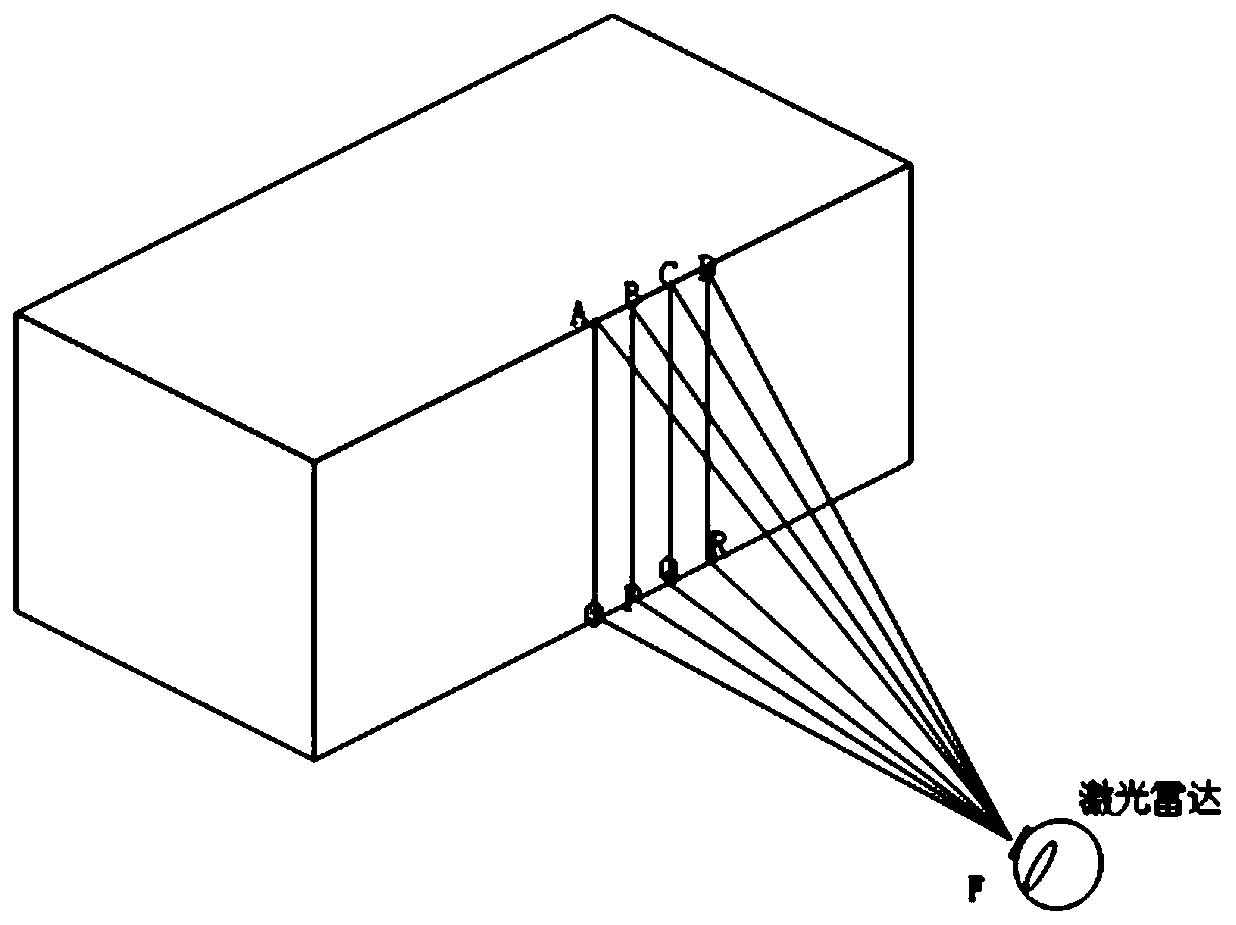

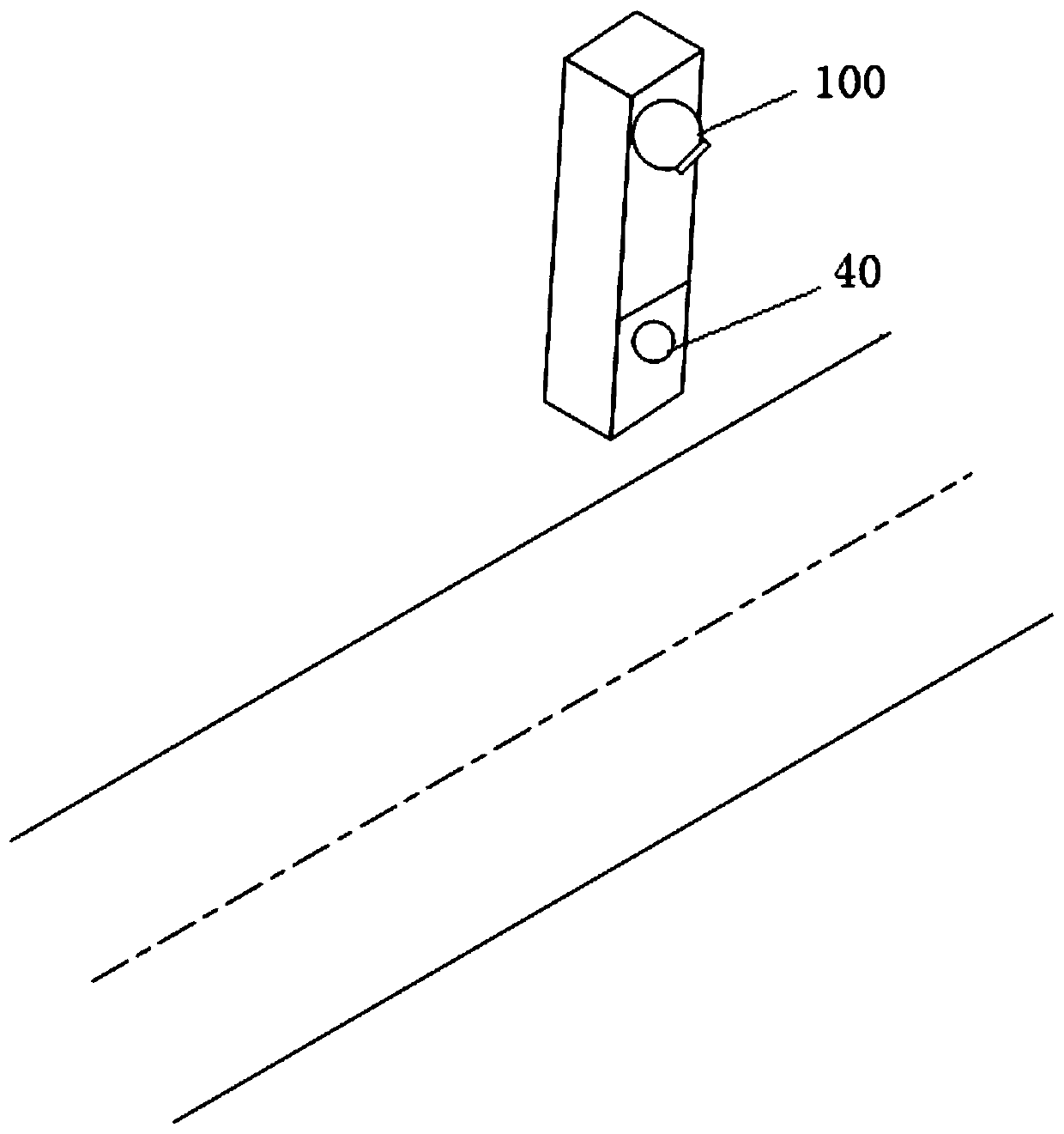

[0035] Such as figure 2 As shown, in a specific embodiment, the scanning module 10 is a laser radar 100, and the laser radar scans the longitudinal section of the vehicle to obtain vehicle longitudinal profile data. More specifically, the laser radar is a fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com