Steel-wood combination column

A steel-wood combination and steel column technology, applied in the direction of columns, pier columns, pillars, etc., can solve the problems of unfavorable environmental protection, increase the self-weight of components, increase the cost of materials and component manufacturing, and achieve increased overall rigidity and optimized mechanical performance , the effect of flexible section arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

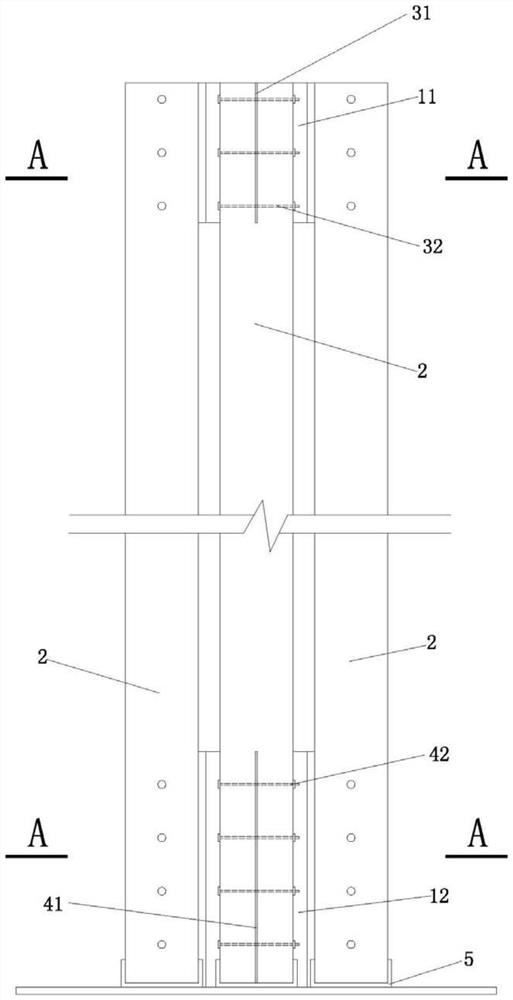

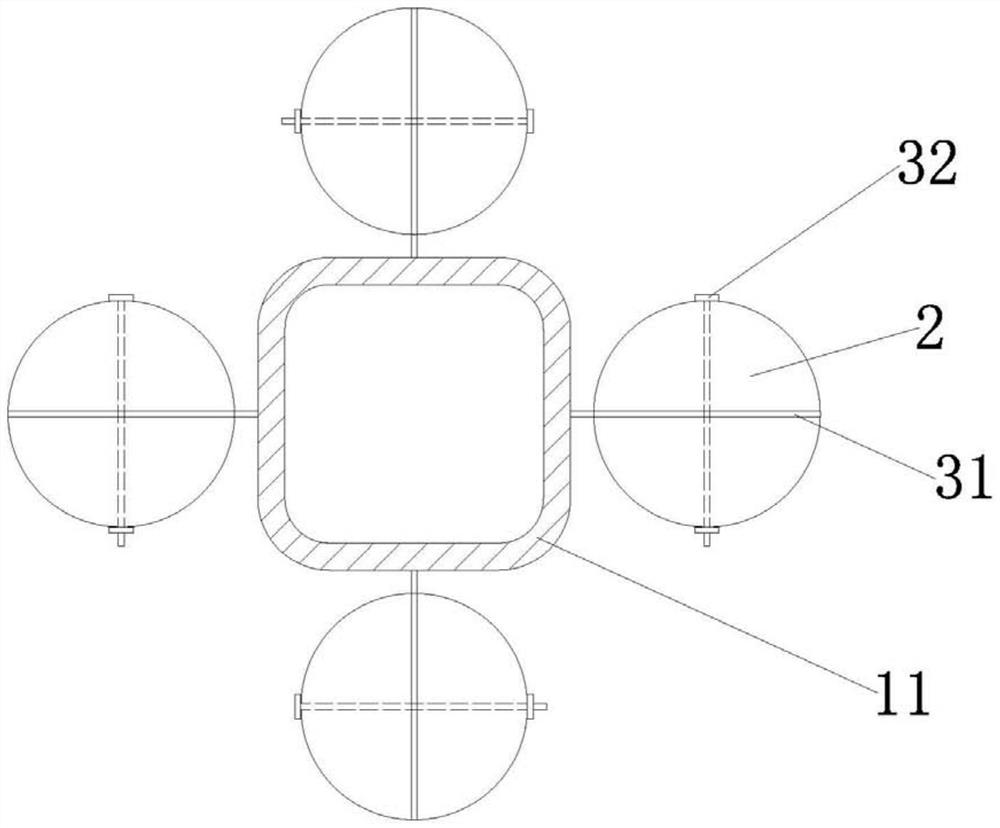

[0020] As shown in each figure, in this embodiment, a steel-wood composite column includes a steel column and a wooden column 2. The steel column includes an upper steel column 11 and a lower steel column 12 to save materials. The upper steel column 11 and the lower steel column 12 are respectively cold-formed thin-walled steel pipes, the height of the upper steel column 11 is 0.8m, the height of the lower steel column 12 is 1m, and the upper steel column 11 and the lower steel column The cross-section of the steel column 12 is quadrangular, and the wooden column 2 has four pieces, which are evenly distributed around the upper steel column 11 and the lower steel column 12. The wooden column 2 is a log, and there is no need to treat the surface. It not only saves production costs, but also is environmentally friendly and beautiful, avoiding landscape engineering that requires materials, and the cold texture and touch of all-steel materials.

[0021] The upper steel column 11 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap