Aluminum alloy formwork stair side sealing edge profile

A technology of aluminum alloy formwork and stairs, which is applied in the direction of formwork/formwork/work frame, connection parts of formwork/formwork/work frame, and on-site preparation of building components, which can solve the problem of difficult calibration and short service life, etc. problems, to achieve the effect of good installation firmness, improved service life and good force uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

[0028] Embodiments of the invention are:

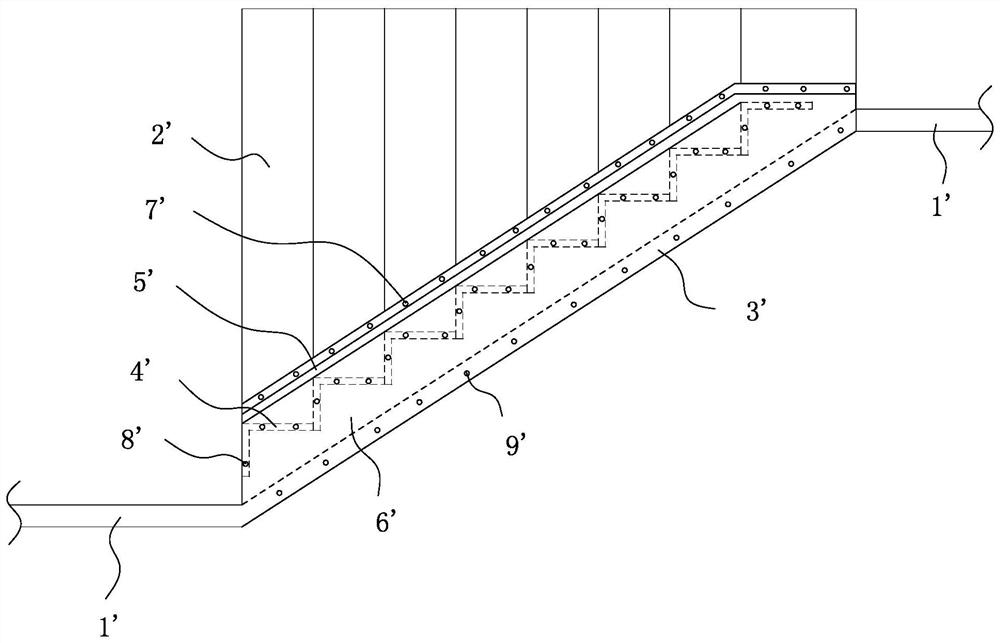

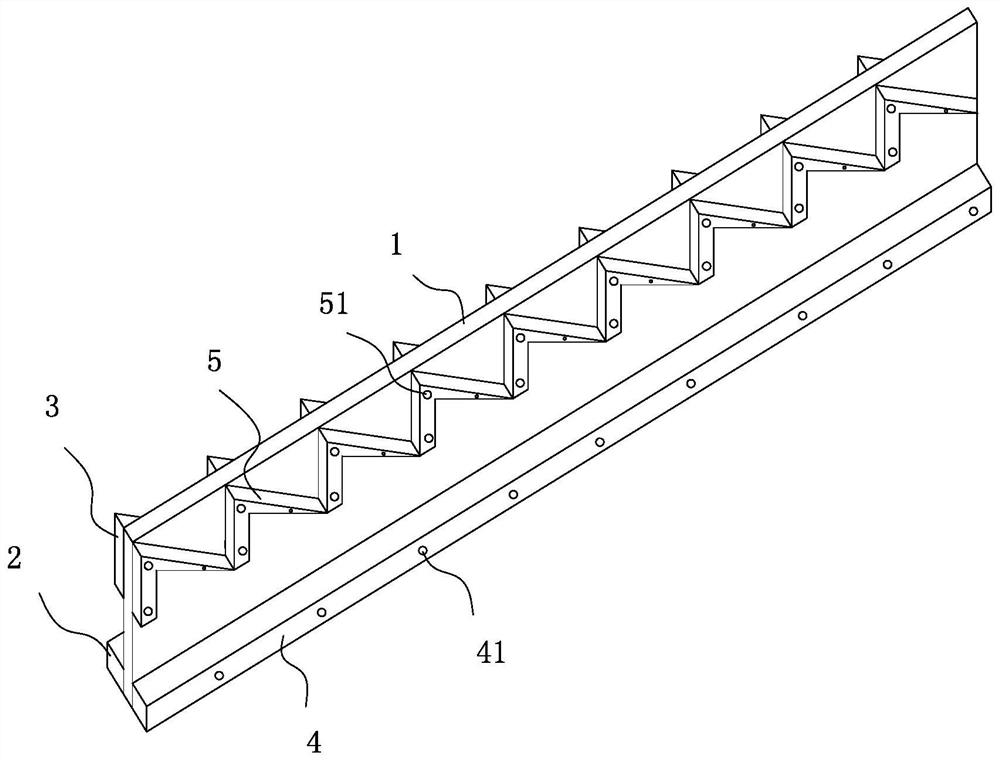

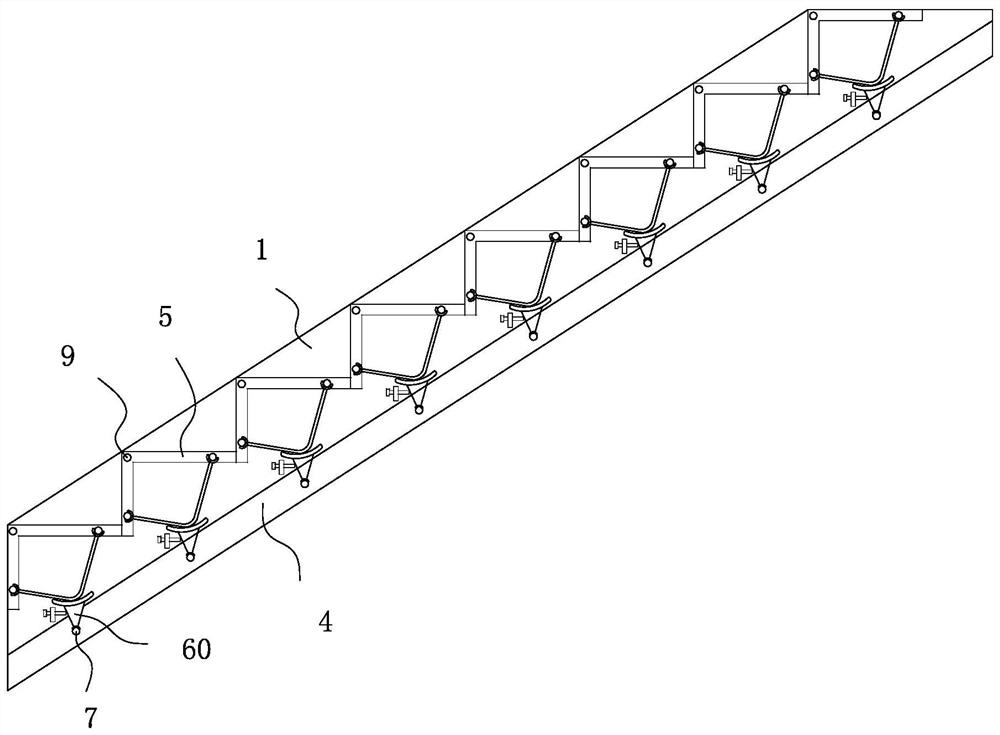

[0029] refer to figure 2 , image 3 and Figure 11 As shown, a side sealing profile of an aluminum alloy formwork staircase includes a side sealing plate 1 with a plate-like structure, and the side of the side sealing plate 1 that is in contact with the top plate 4' is defined as the inner side, and the other side is the outer side. Side, define one side along the width direction of the side sealing plate 1 as the upper side edge, and the other side edge as the lower side edge, and the lower side edge of the inner surface of the side sealing plate 1 abuts against the first connecting seat 2. The upper edge of the inner surface of the side sealing plate 1 is abutted against a second connecting seat 3, the second connecting seat 3 has an L-shaped structure, and the lower edge of the outer surface of the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com