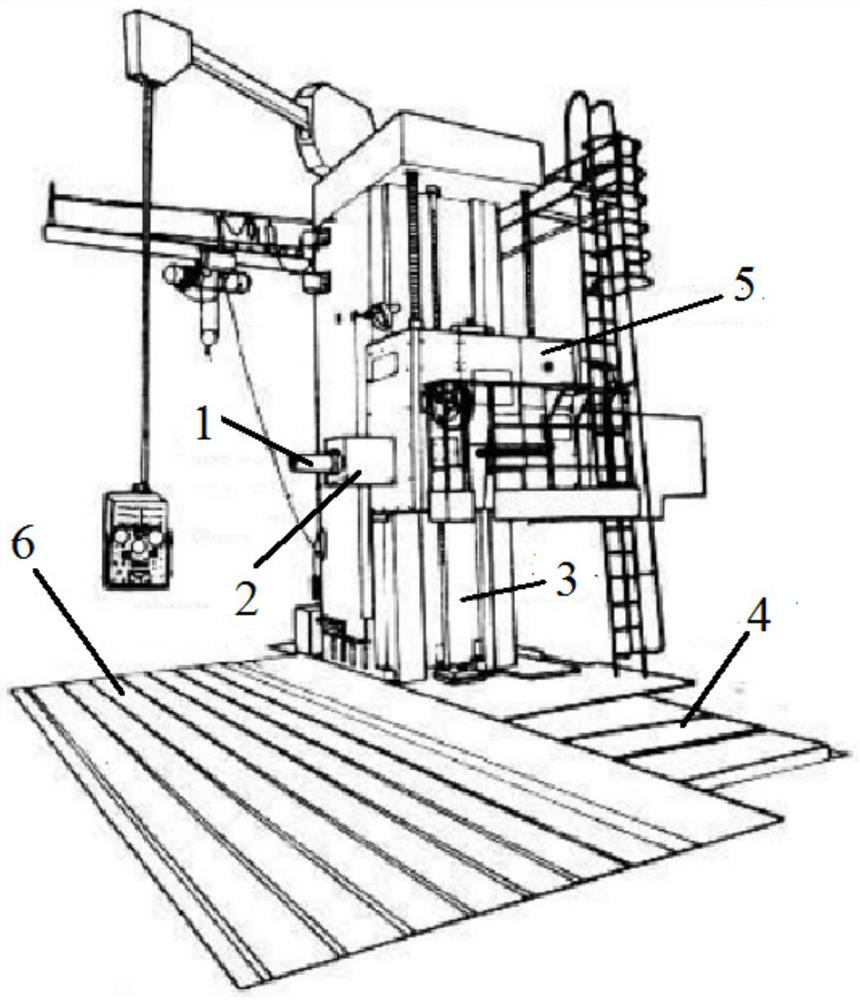

A method to prevent the simultaneous feeding of the boring shaft and the ram of the floor milling and boring machine

A technology for milling and boring machines and boring shafts is applied in the field of preventing simultaneous feeding of boring shafts and rams of floor milling and boring machines. Accuracy, shortening maintenance man-hours, and reducing the effect of downtime failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

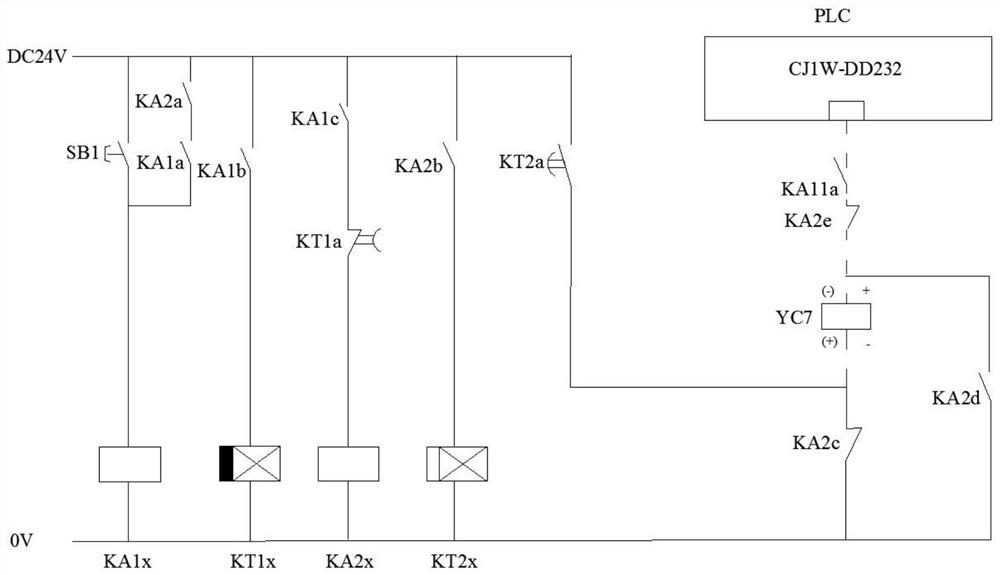

[0037] The voltage of the line to which the PLC is connected is greater than the voltage of the low-voltage power line.

[0039] The high-voltage power supply line voltage described in the present invention is 24V, and the low-voltage power supply line voltage is 0V.

[0040] In the present invention, the relay KT2 is a power-on delay relay. Relay KT2 selects delay relay energization delay

[0048] The specific time T1 is set according to the remanence of the friction plate.

[0049] The above-mentioned control circuit is used to eliminate the specific process of the remanence of the friction plate, wherein T1=300s, T2=5s:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com