Backstop, motor device, curtain control device and electric curtain

A backstop and backstop technology, applied in clutches, transmission boxes, mechanical equipment, etc., can solve the problems of poor durability and complex structure of the backstop, and achieve the effect of simple internal structure and less failure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

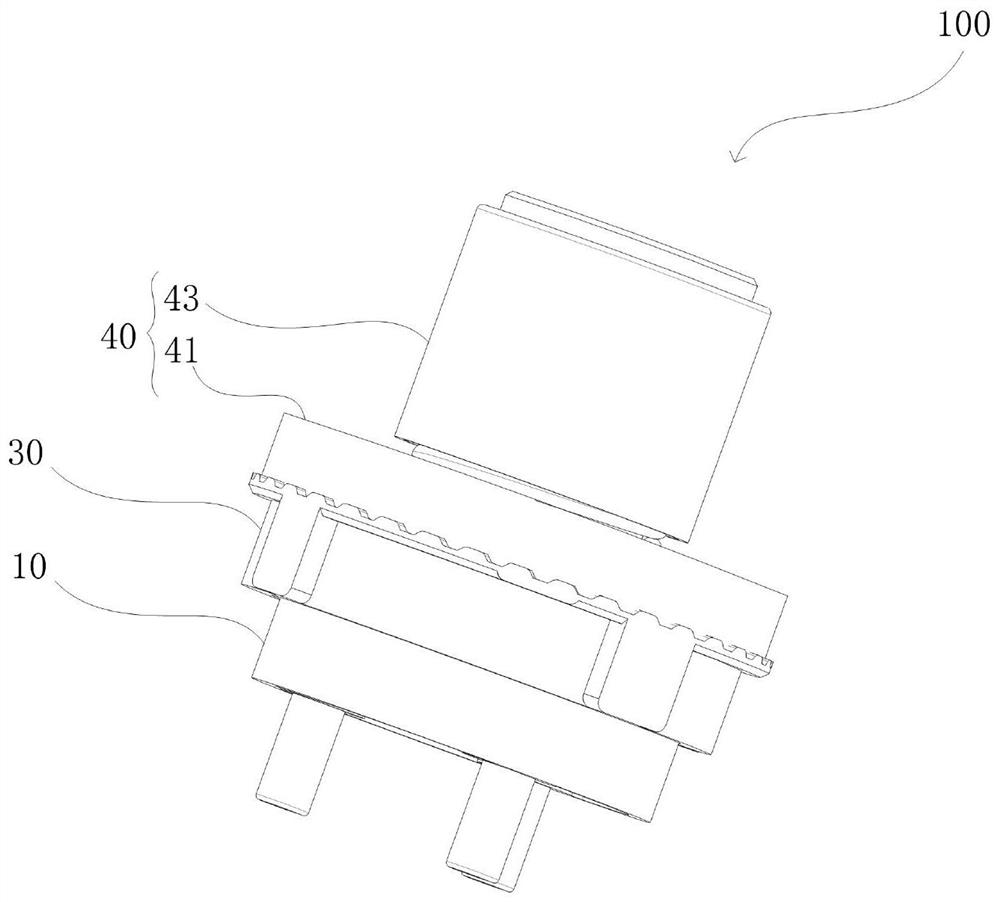

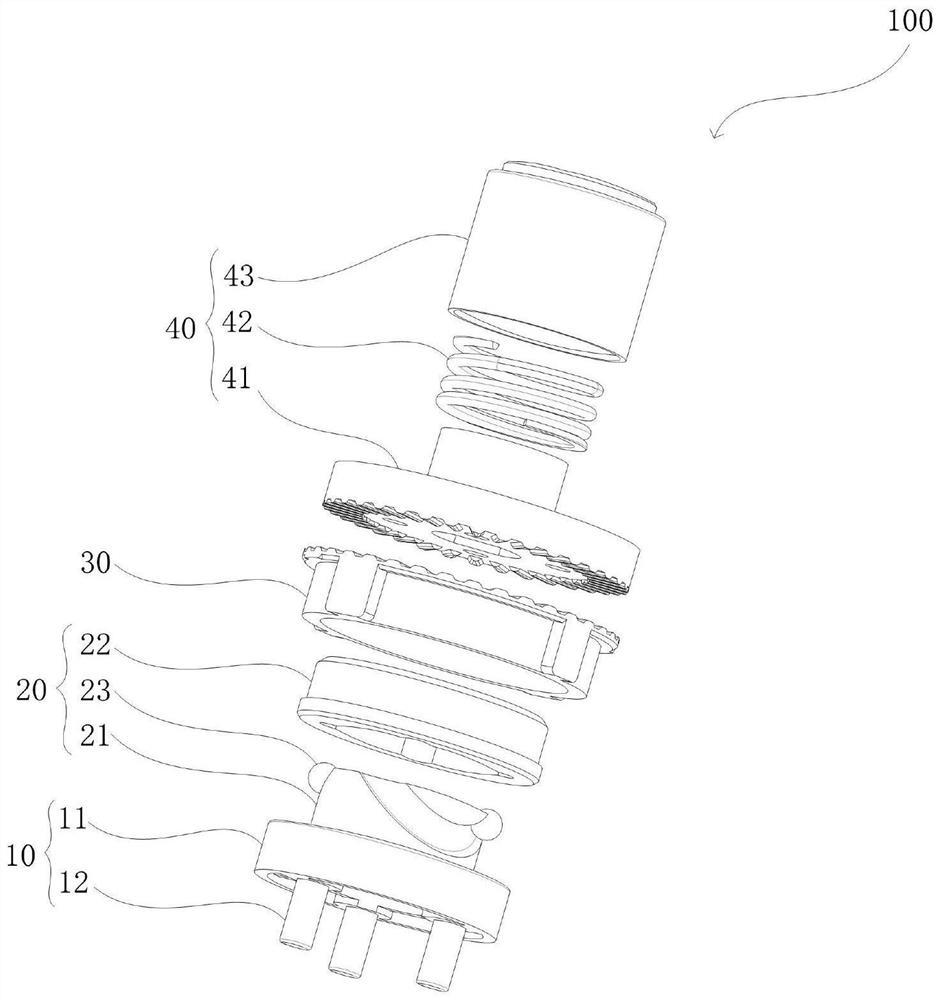

[0039] see figure 1 and figure 2 , which is a structural schematic diagram of a backstop 100 provided in the first embodiment of the present invention. The backstop 100 includes, for example, a driving force receiving part 10 , a control part 20 , a fixing sleeve 30 and a driving force output part 40 . The control unit 20 is disposed on one side of the driving force receiving unit 10 , and the driving force output unit 40 is co-located with the control unit 20 on a side away from the driving force receiving unit 10 .

[0040] Specifically, the driving force receiving part 10 includes, for example: an installation platform 11 and a driving force receiving part 12 . Wherein, the installation platform 11 is connected to the control unit 20; the driving force receiving member 12 is disposed on the side of the installation platform 11 away from the control unit 20, and is used for connecting the motor drive shaft.

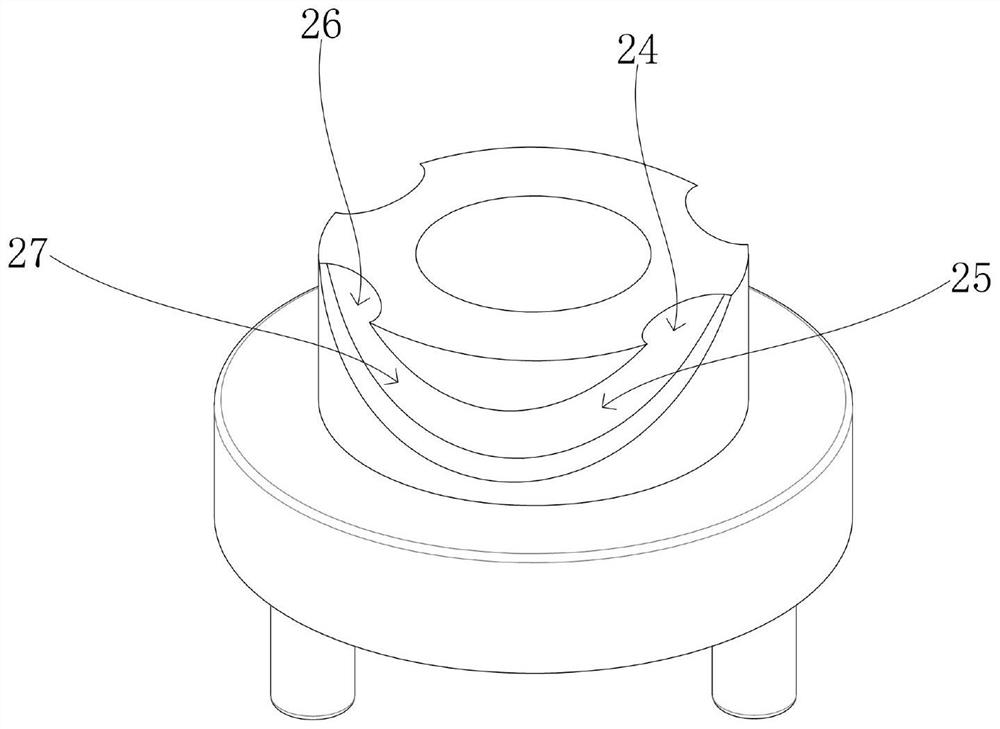

[0041] Specifically, see figure 2 , the control unit 20 inclu...

no. 2 example

[0052] see Figure 9 , which is a schematic structural diagram of a motor device 200 provided in the second embodiment of the present invention. The motor device 200 includes, for example: the backstop 100 as described in the first embodiment and the motor body 210 connected to the backstop 100 .

[0053] Specifically, the motor body 210 has a driving shaft 211 for outputting driving force, and the driving shaft 211 is connected to the driving force receiving portion 10 of the backstop 100 . For example, the driving force receiving part 11 provided on the driving force receiving part 10 is a connecting shaft hole, and the driving shaft 211 is inserted into the connecting shaft hole, so that the motor body 210 can output the forward or reverse driving force to the driving force. Receiver 10.

[0054] For example, the driving force output portion 40 of the backstop 100 may also be provided with an output connection position (not shown in the figure), and the output connection ...

no. 3 example

[0057] see Figure 10 , which is a schematic structural diagram of a curtain control device 300 provided in the third embodiment of the present invention. The curtain control device 300 includes, for example, the motor device 200 and the drum assembly 310 as described in the second embodiment. The motor device 200 is placed inside the reel assembly 310 , and when the motor device 200 rotates, it will drive the reel assembly 310 to rotate.

[0058] Preferably, the reel assembly 310 includes: a reel 311, a first installation position 312, a second installation position 313, and a transmission wheel 314; further, the motor device 200 is provided with a motor body 210 at one end and an output shaft 220 at the other end; Wherein, the motor body 210 is connected to the second installation position 313 , and the output shaft 220 is connected to the transmission wheel 314 .

[0059] Preferably, the first installation position 312 is an installation cylinder, and the installation cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com