Method and system for optimizing vibration monitoring position of wind power gear box, medium and equipment

A wind power gearbox and vibration monitoring technology, applied in the field of wind power, can solve problems such as inability to perform direct measurement and attenuation, and achieve the effect of optimizing sensor position matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

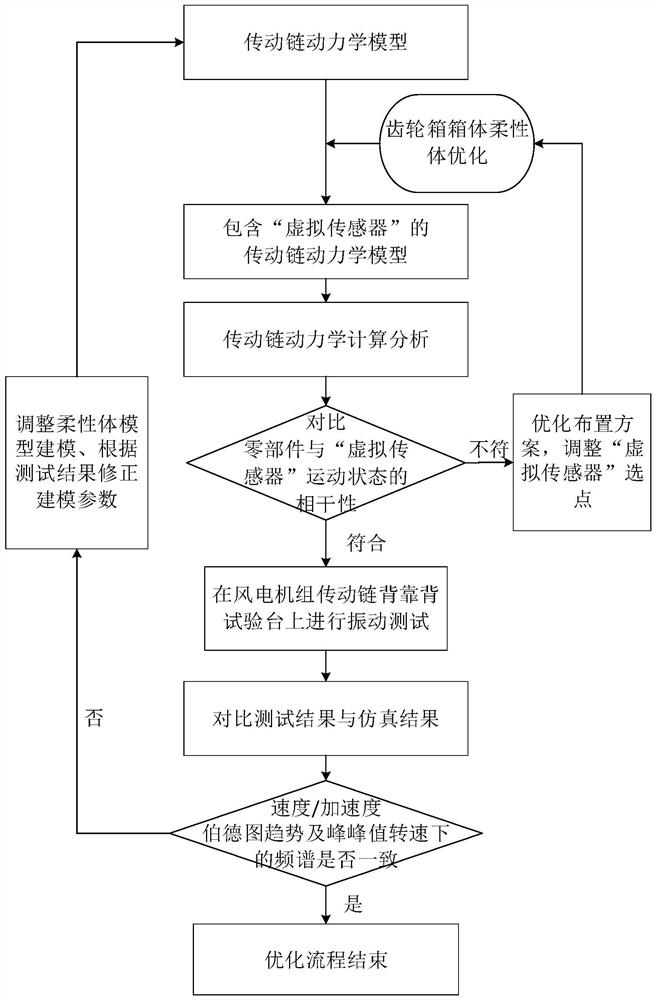

[0039] like figure 1 As shown, the wind power gearbox vibration monitoring position optimization method of this embodiment includes the following steps:

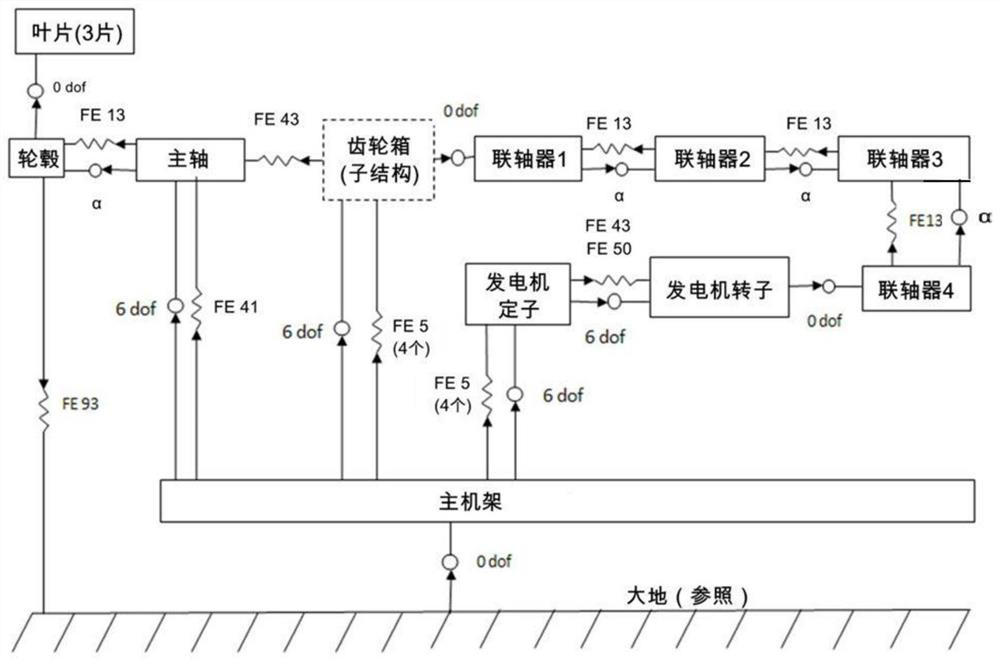

[0040] S01. Establish a multi-body dynamics model of the wind turbine transmission system;

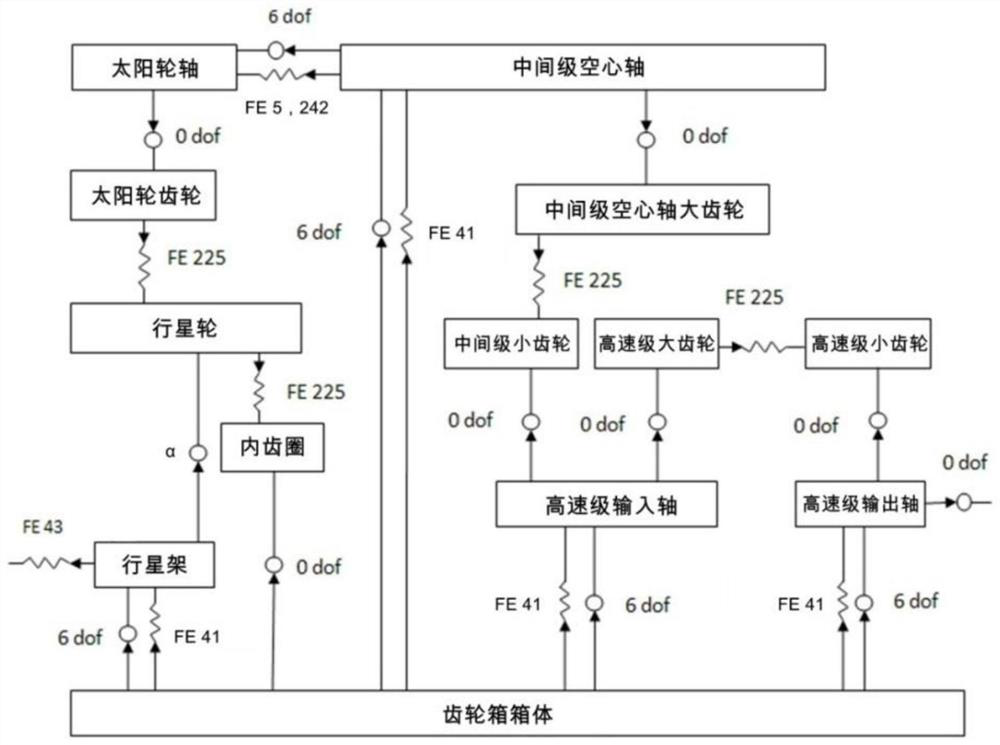

[0041] S02. Optimizing the multi-body dynamics model of the wind turbine transmission system: do a flexible body modeling for the gearbox case, select multiple reference positions for each monitoring point on the surface of the case body corresponding to the gear pairs of all levels of the gearbox, respectively Use the master node for binding as a virtual sensor;

[0042] S03. Carry out dynamic calculation on the pre-built simulation model of the transmission chain of the wind turbine, obtain the motion state of each component inside the gearbox and the virtual sensor, and construct the relationship...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com