Metal mold gravity casting mold

A gravity casting, metal mold technology, applied in the field of metal mold gravity casting molds, can solve problems such as stuck in holes and shape damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

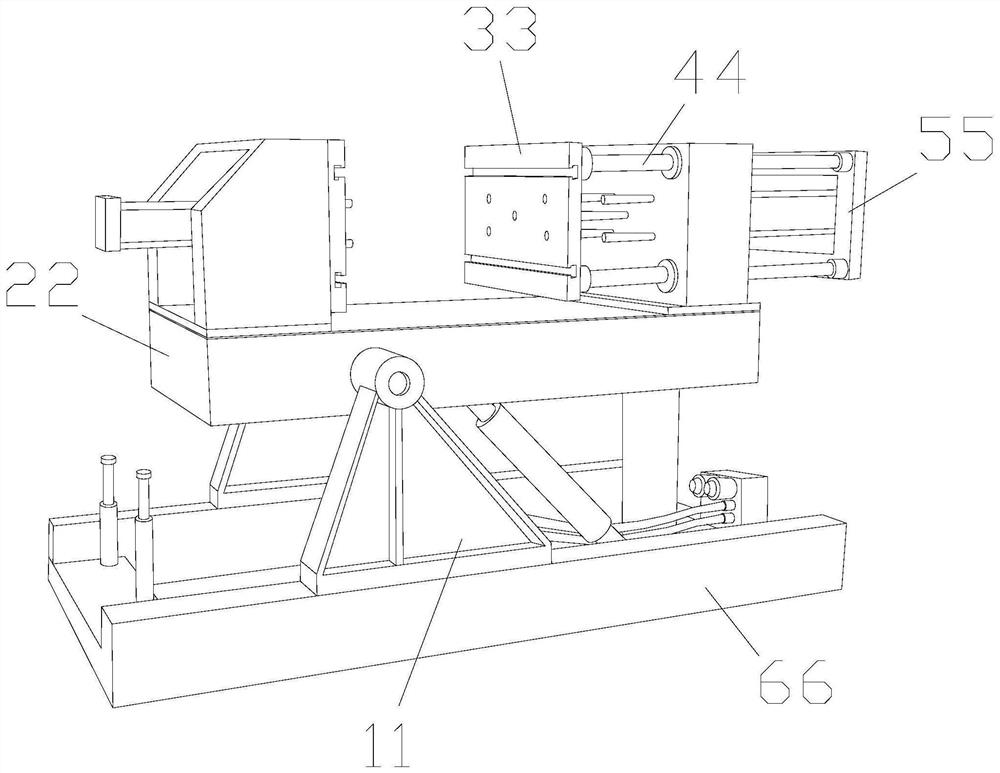

[0032] as attached figure 1 to attach Image 6 Shown:

[0033] The present invention provides a metal type gravity casting mold, the structure of which includes a support plate 11, a heavy pressure table 22, a heavy pressure plate 33, a support rod 44, a stripping plate 55, and a base 66. The support plate 11 is welded to the upper surface of the base 66, The end of the support plate 11 away from the base 66 is connected to the weight table 22 , the strut 44 is connected to the weight plate 33 , and the stripping plate 55 penetrates inside the weight plate 33 and is movably connected.

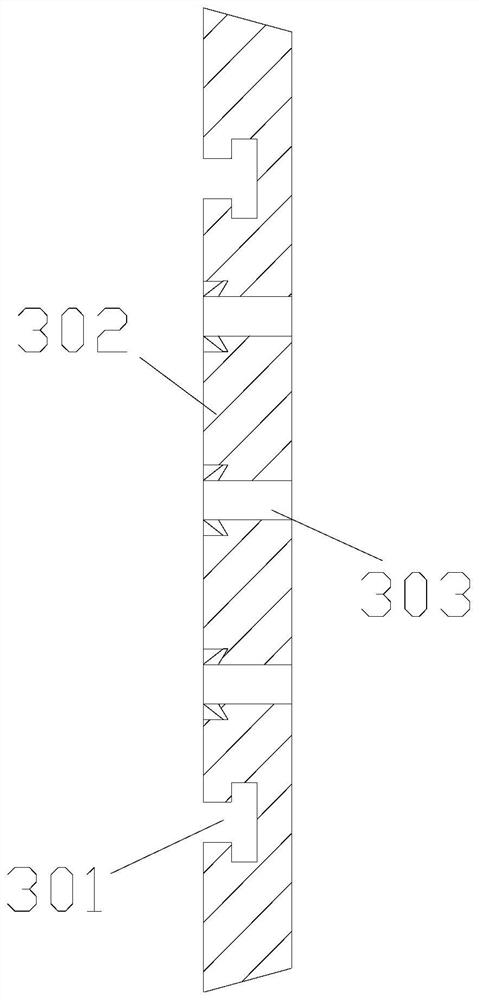

[0034] The heavy pressure plate 33 includes a notch 301 , a main block 302 , and a through opening 303 , the notch 301 and the main block 302 are an integrated structure, and the through opening 303 runs through the main block 302 .

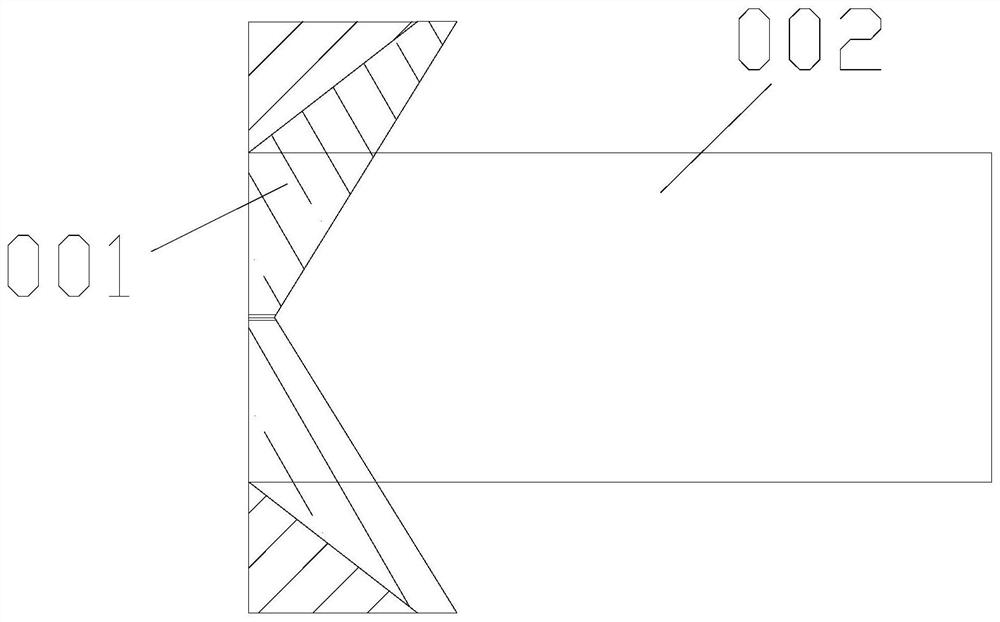

[0035] Wherein, the port 303 includes a one-way block 001 and an air port 002, the one-way block 001 is connected to the air port 002, the one-way block 001 is ...

Embodiment 2

[0042] as attached Figure 7 to attach Figure 9 Shown:

[0043] Wherein, the solid block 111 includes a connecting body s01, a hard body s02, an adhesive layer s03, and a stretching body s04. The adhesive layer s03 is attached to the outer surface of the connecting body s01, and the connecting body s01 is fixed on the outside of the hard body s02. On the surface, the end of the connecting body s01 away from the hard body s02 is connected to the exhibition body s04, the rubber layer s03 is made of rubber material and has a certain toughness, the hard body s02 is a triangular structure, and the hard body s02 fixes the overall hard force, the connecting body s01 is connected between the force receiving part and the fixed part, and plays the role of connecting and buffering, and the extending body s04 expands according to the external force.

[0044] Wherein, the connecting body s01 includes a ball core 511, a total support body 512, and a rubber extension body 513. The ball co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com