Swing type rolled steel shearing waste collecting device

A waste collection and swinging technology, which is applied in the direction of shearing devices, shearing machine accessories, maintenance and safety accessories, etc., can solve the lack of waste weight data collection function, which is not conducive to the intelligent development of steel rolling, and the space utilization rate of the collection frame is low and other problems, to achieve the effect of flexible and reliable action, novel and compact overall structure, and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

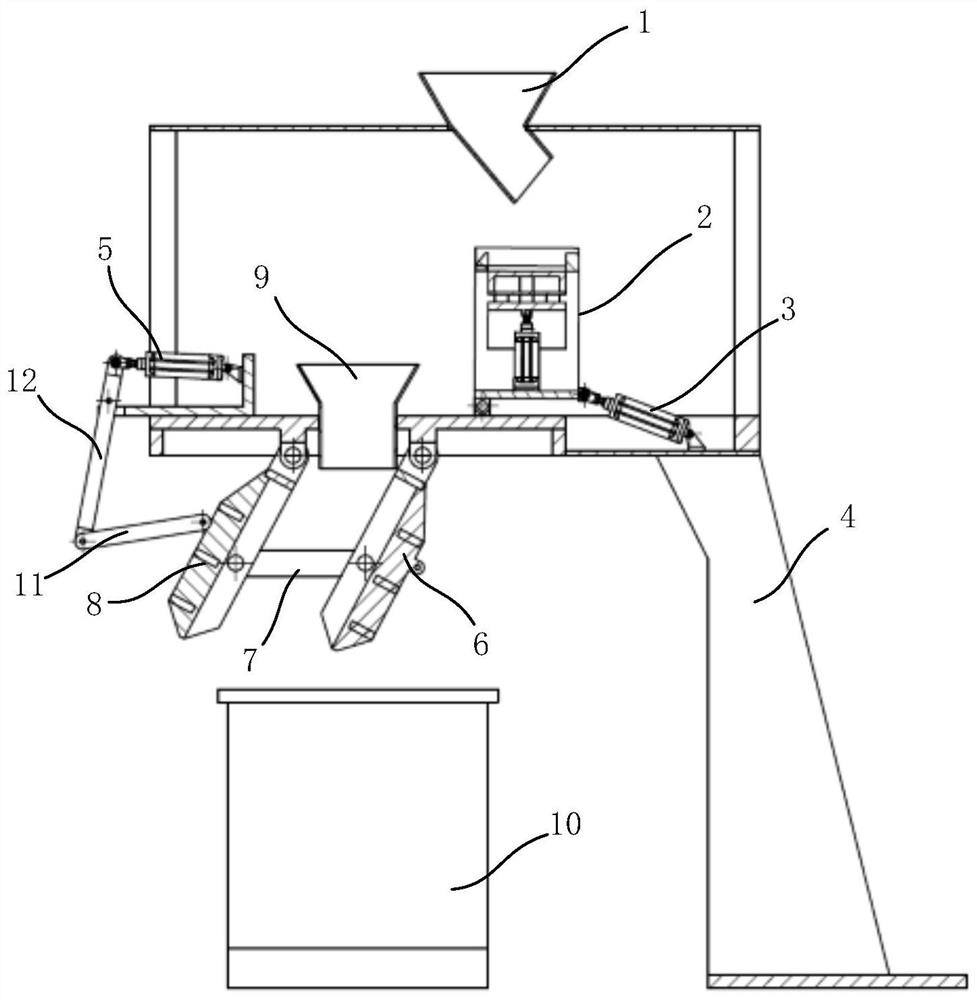

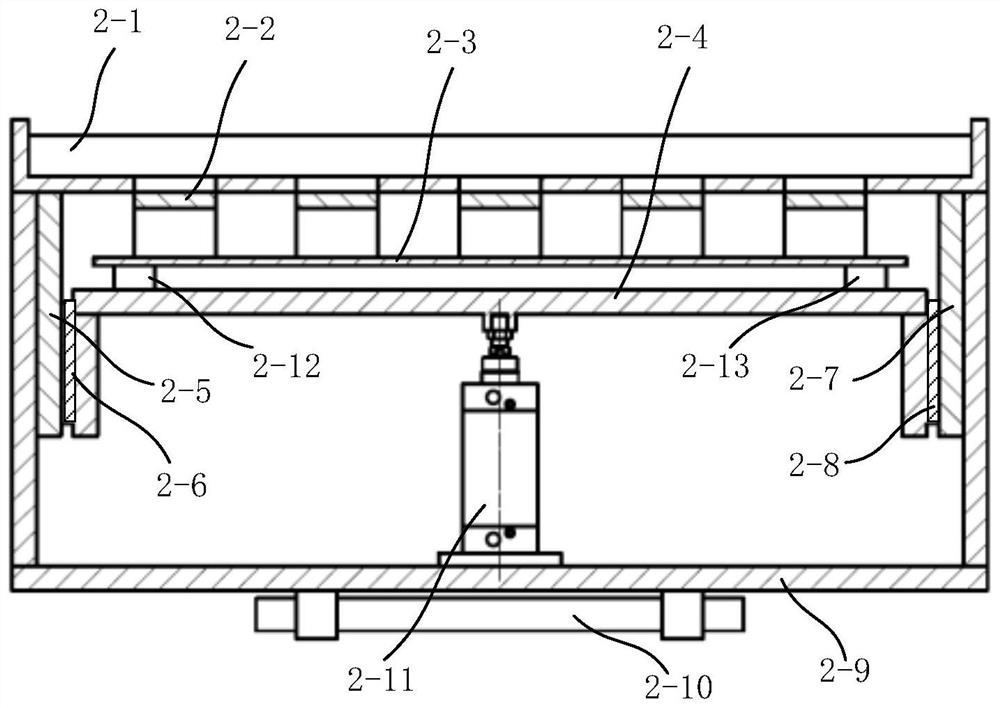

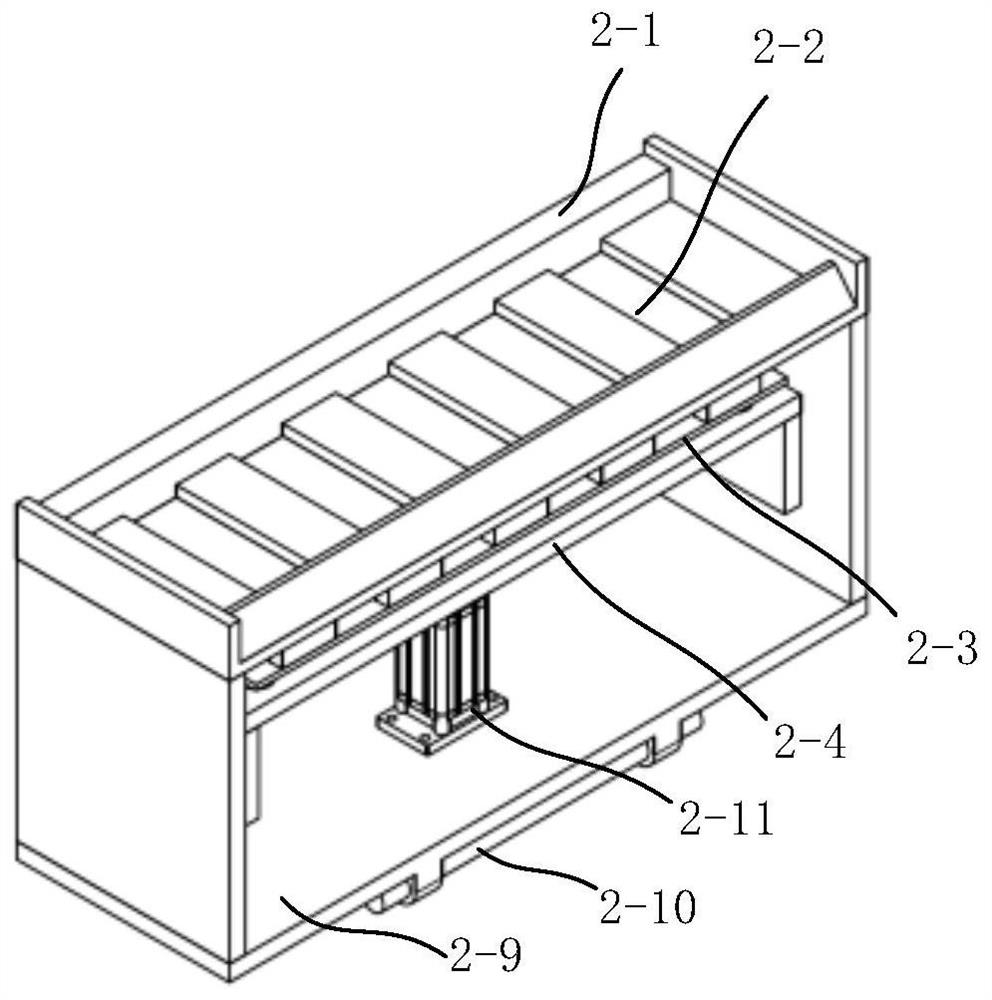

[0019] The swing-type steel rolling shear waste collection device of the present invention includes: a chute, a weighing platform, a dumping cylinder, a bracket, a swing cylinder, a first swing chute, a connecting rod, a second swing chute, a blanking slide, and a collection frame , the first swing link and the second swing link;

[0020] Includes stand;

[0021] A weighing platform is arranged on the support, one end of the weighing platform bottom is hinged with the support, the other end is hinged with the piston rod of the dumping cylinder, and the cylinder tail of the dumping cylinder is hinged with the bracket;

[0022] A blanking chute is provided on the dumping side of the weighing platform, and the blanking chute is arranged in the through hole of the bracket, and a first swing chute and a second swing chute are arranged on both sides of the lower outlet of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com