Assembling, welding and pressing jig for 5G communication mobile phone antenna FPC

A technology for mobile phone antennas and pressing fixtures, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of overall convenience, stability and practicability, damage to PCB boards and FPC boards, Problems affecting the product pass rate, etc., achieve the effects of high stability and practicability, improved welding pass rate, and convenient and fast welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

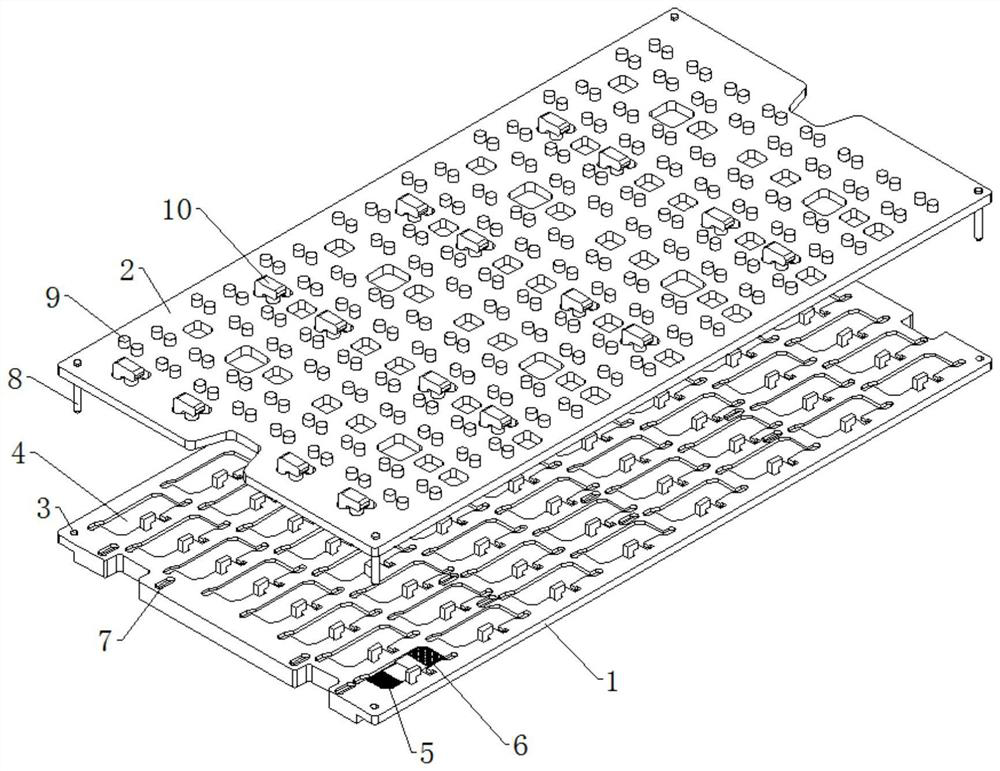

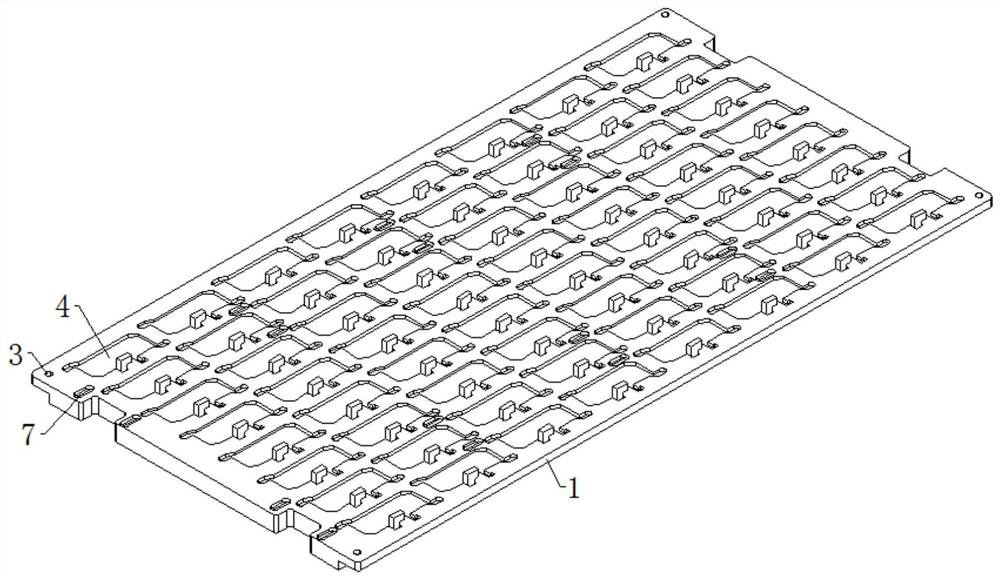

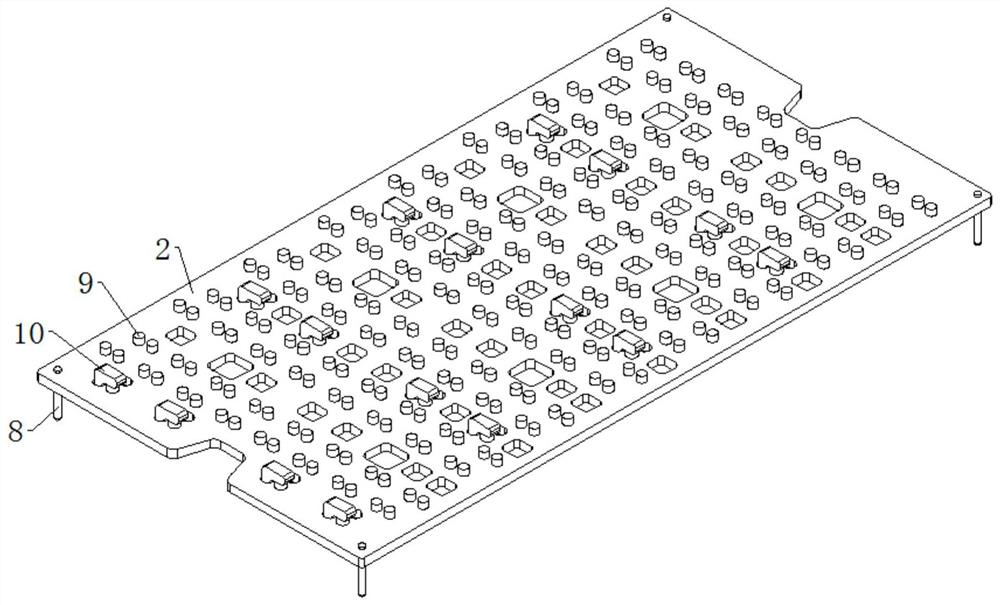

[0020] Examples, see Figure 1-3 , the present invention provides a technical solution: a 5G communication mobile phone antenna FPC assembly welding pressing fixture, including a fixture base 1 and a fixture gland 2, characterized in that: the corners of the upper surface of the fixture base 1 are equipped with positioning hole 3, the upper surface of the fixture base 1 is uniformly provided with a number of limit grooves 4, the inside of the limit grooves 4 are respectively placed PCB board 5 and FPC board 6, the upper surface of the fixture base 1 is located between the limit grooves 4 Correspondingly, there is a clamping groove 7, and the corner of the bottom of the fixture gland 2 is correspondingly provided with a positioning column 8, and a number of PIN thimbles 9 are uniformly arranged on the bottom of the fixture gland 2 and corresponding to the position of the limit groove 4, and the fixture pressure An automation knob 10 is provided at the bottom of the cover 2 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com