Efficient glazing device for silicon carbide ceramic for new material

A technology of silicon carbide ceramics and new materials, applied in the direction of ceramic molding machines, manufacturing tools, etc., can solve the problems of low work efficiency and manpower consumption, and achieve the effect of saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

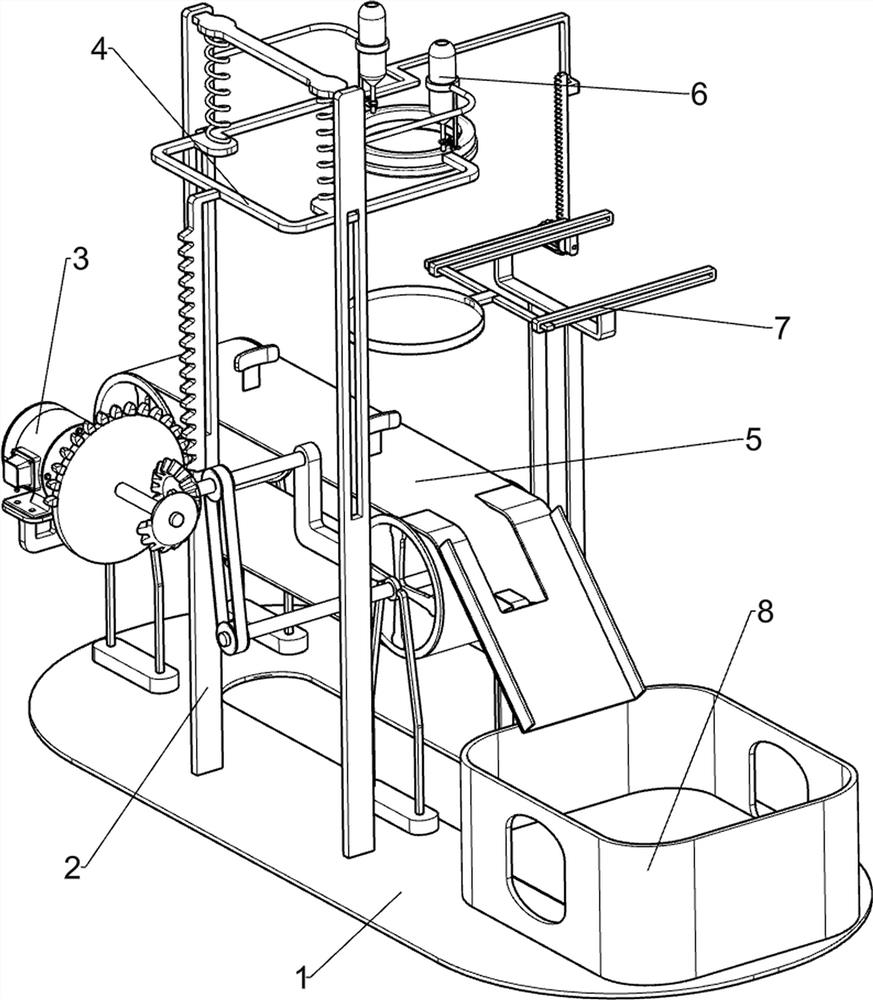

[0029] A high-efficiency glazing device for silicon carbide ceramics for new materials, such as Figure 1-3 As shown, it includes a bottom plate 1, a first sliding guide frame 2, a driving mechanism 3 and a lifting mechanism 4, the top right side of the bottom plate 1 is connected with a first sliding sliding frame 2, and the first sliding sliding frame 2 is provided with a driving mechanism 3, A lifting mechanism 4 is provided between the driving mechanism 3 and the first guide carriage 2, and the driving mechanism 3 and the lifting mechanism 4 are connected by transmission.

[0030] The driving mechanism 3 includes a first fixed mount 31, a low-speed motor 32 and a rotating shaft 33, the first guide carriage 2 right side is connected with the first fixed mount 31, the first fixed mount 31 is equipped with a low-speed motor 32, and the low-speed motor 32 A rotating shaft 33 is connected to the output shaft.

[0031] The lifting mechanism 4 includes a sector gear 41, a limit ...

Embodiment 2

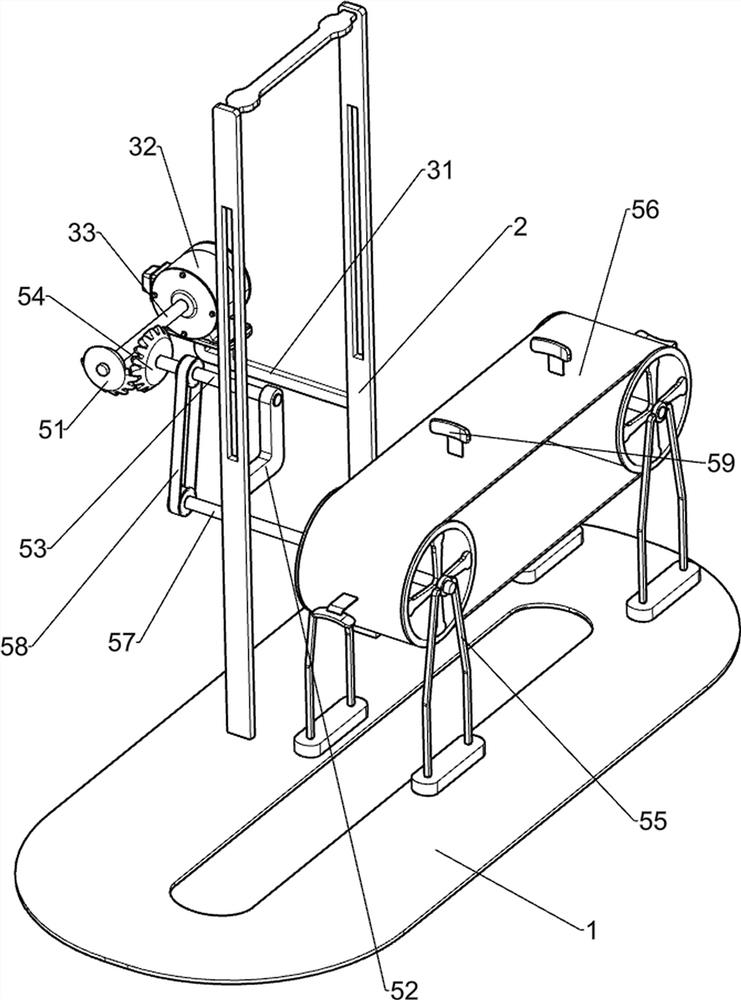

[0034] On the basis of Example 1, such as Figure 4 As shown, a transmission mechanism 5 is also included, and the transmission mechanism 5 includes a sector bevel gear 51, a second fixed mount 52, a first connecting shaft 53, a transmission bevel gear 54, a support frame 55, a belt transmission group 56, a second connecting shaft 57, flat belt 58 and block 59, bevel sector gear 51 is connected on the rotating shaft 33, the second fixed frame 52 is connected on the first guide carriage 2, the first connecting shaft 53 is connected with the rotation type on the second fixed frame 52 , the first connecting shaft 53 is connected with a transmission bevel gear 54, the sector bevel gear 51 will mesh with the transmission bevel gear 54, two support frames 55 are connected to the top of the bottom plate 1, and a belt transmission group is wound between the upper parts of the two support frames 55 56, one of the power transmission shafts of the belt transmission group 56 is connected ...

Embodiment 3

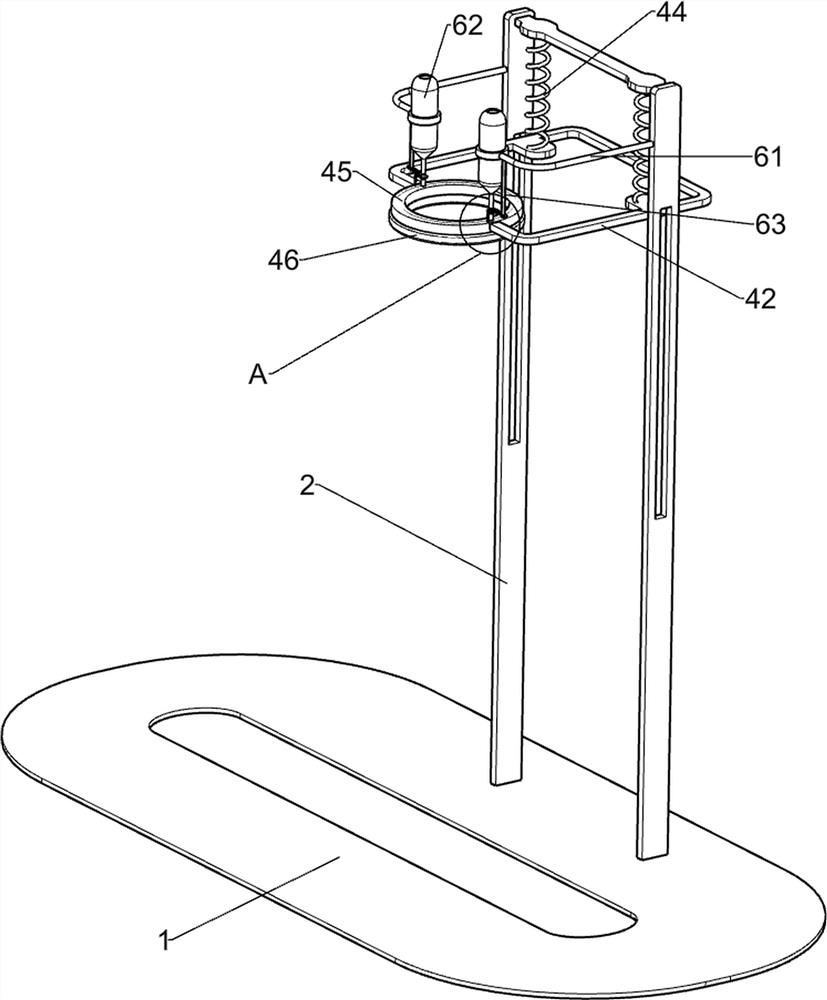

[0039] On the basis of Example 2, such as image 3 and Figure 7 As shown, it also includes a stopper mechanism 7, the stopper mechanism 7 includes a second rack 71, a second guide carriage 72, a glaze box 73, a third rack 74 and a spur gear 75, on the limit frame 42 A second rack 71 is connected, a second guide carriage 72 is connected to the left side of the top of the bottom plate 1, a glaze connection box 73 is slidingly connected to the second guide carriage 72, and a third rack 74 is connected to the glaze connection box 73 , The second guide carriage 72 is rotatably connected with a spur gear 75, and the spur gear 75 meshes with the second rack 71 and the third rack 74 respectively.

[0040] When there are more glaze liquids in the brushing glaze foam cotton 46, the excess glaze liquid on it will be dripped in the glaze receiving box 73, and the stop frame 42 drives the second tooth bar 71 to move downward when moving downward. After the tooth bar 71 moves down to mes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com