Sand-containing glaze coating as well as preparation method and application thereof

A glaze and coating technology, applied in anti-corrosion coatings, multi-color effect coatings, coatings, etc., can solve problems such as grinding hands, hidden dangers of babies or young children, and large particle size of natural sand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

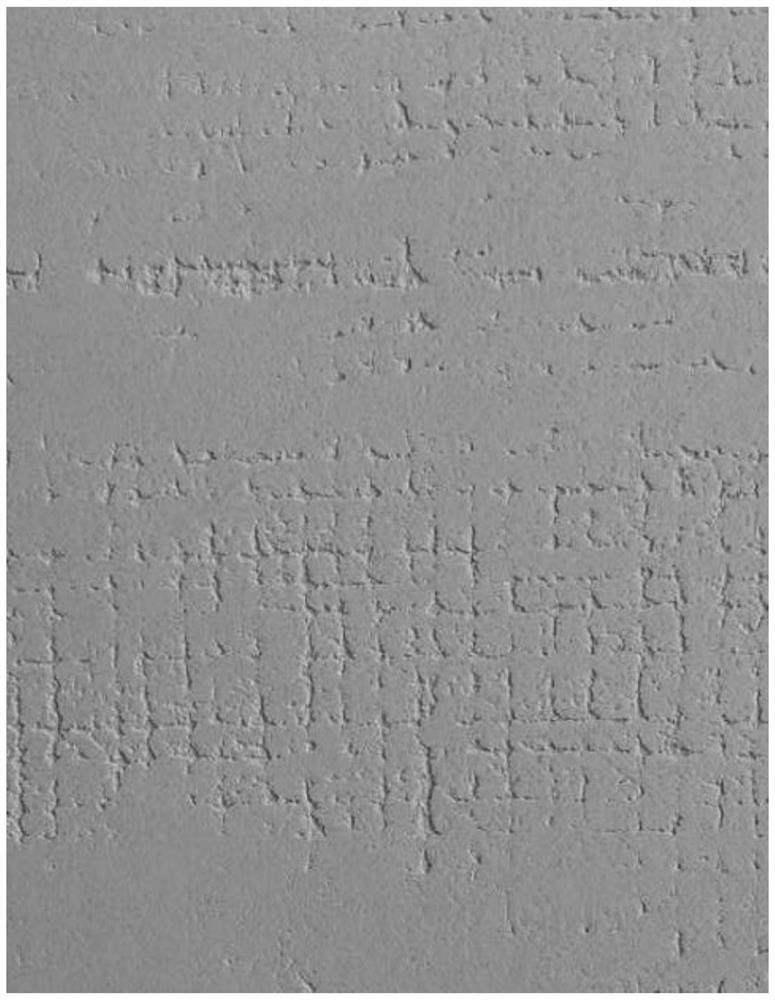

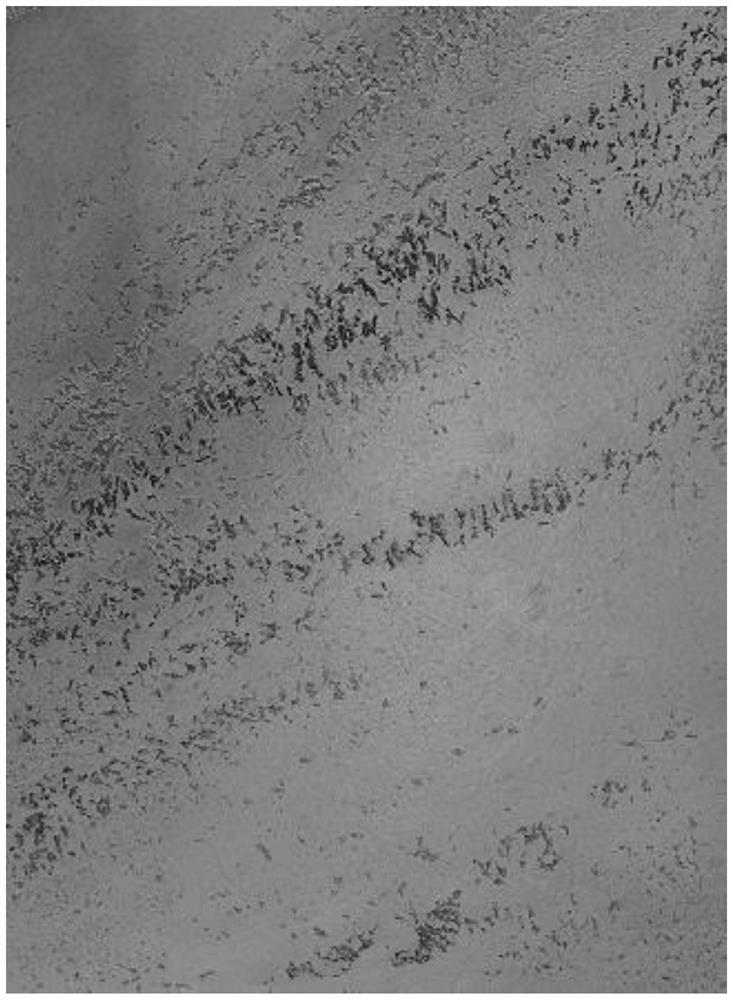

Image

Examples

preparation example Construction

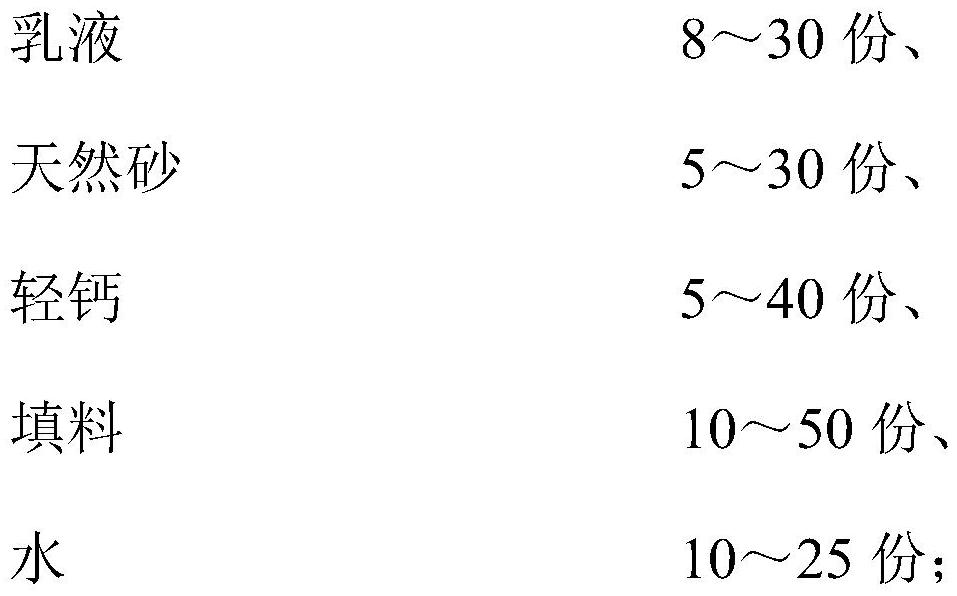

[0073] The present invention also provides a kind of preparation method of above-mentioned sand-containing glaze coating, comprising the following steps:

[0074] Mix said emulsion, natural sand, light calcium, filler and water.

[0075] Preferably, for formula containing emulsion, natural sand, light calcium, filler, water, cellulose, bentonite, alkali swelling thickener, dispersant, wetting agent, defoamer, film-forming aid, pH regulator, And the sand-containing glaze coating of preservative, its preparation method comprises the following steps;

[0076] (1) Pre-mixing: Dissolve cellulose in part of the water, then add dispersant, wetting agent, defoamer, film-forming aid, pH regulator while stirring, add emulsion and stir after dispersing for 1-5 minutes , Mixture A was prepared after stirring.

[0077] (2) Dispersion: Add bentonite, titanium dioxide, light calcium and fillers to mixture A under stirring, add natural sand after stirring for 15-20 minutes, and continue sti...

Embodiment 1

[0085] This embodiment provides a sand-containing glaze paint and a preparation method thereof.

[0086] (1) In parts by weight, the preparation raw materials of sand-containing glaze coating 1 are as follows:

[0087]

[0088]

[0089] Among them, the sedimentation volume of light calcium is 2.8mL / g.

[0090] (2) Preparation of sand-containing glaze coating 1:

[0091] (1) Pre-mixing: Dissolve cellulose in 50% water, then add dispersant, wetting agent, defoamer, film-forming aid, pH regulator while stirring, add emulsion after dispersing for 1-5 minutes and After stirring, Mixture A was prepared.

[0092] (2) Dispersion: Add bentonite, titanium dioxide, light calcium and heavy calcium to mixture A under stirring, add natural sand after stirring for 15-20 minutes, and continue stirring to obtain mixture B.

[0093] (3) Viscosity adjustment: Add preservative, alkali swelling thickener and remaining water to the stirring mixture B, and stir evenly to prepare sand-contai...

Embodiment 2

[0095] This embodiment provides a sand-containing glaze paint and a preparation method thereof.

[0096] (1) In parts by weight, the preparation raw materials of sand-containing glaze coating 2 are as follows:

[0097]

[0098]

[0099] Among them, the sedimentation volume of light calcium is 2.8mL / g.

[0100] (2) Preparation of sand-containing glaze coating 2:

[0101] The usage content of the raw materials in the coating was changed, and the preparation method was the same as in Example 1 to obtain the sand-containing glaze coating 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sedimentation volume | aaaaa | aaaaa |

| Sedimentation volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com