Injection molding equipment for plug injection molding

A technology of injection molding and injection equipment, applied in the direction of coating, etc., can solve the problems of lack of positioning of plug terminals, easy skew of plug terminals, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

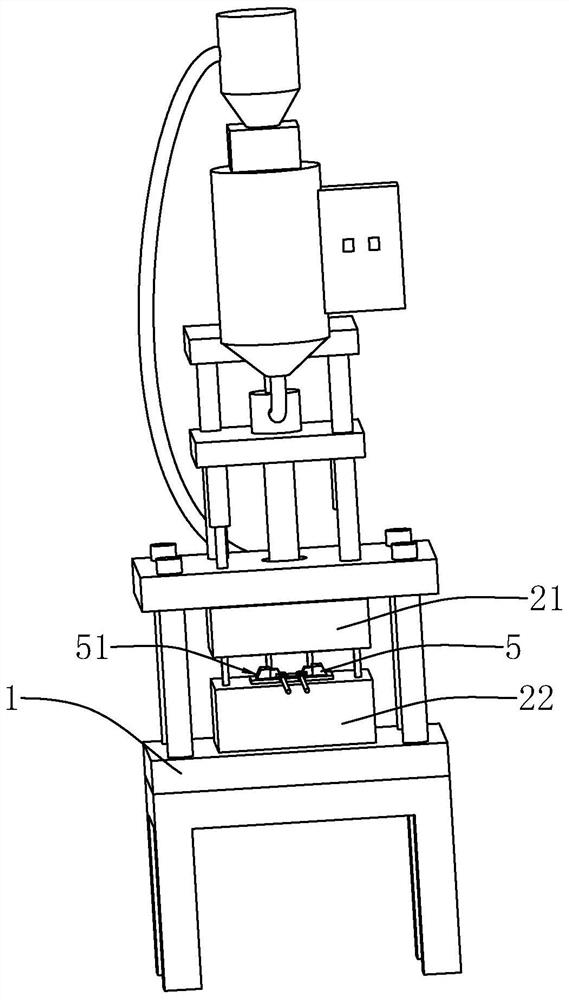

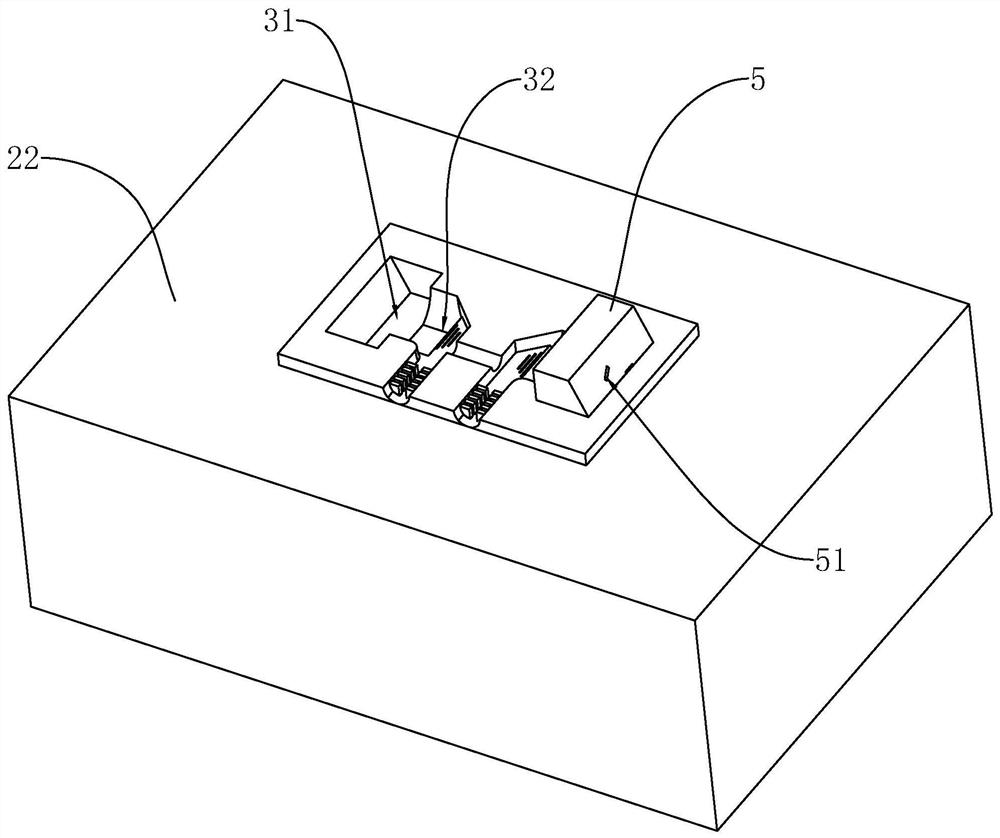

[0037] refer to figure 1 and figure 2 , including machine base 1, terminal holder 5 and injection molding device, injection molding device includes lower mold 22, upper mold 21, driving mechanism and injection mechanism, both driving mechanism and injection mechanism are installed on the machine base 1, and upper mold 21 is fixed Installed on the driving mechanism, the lower mold 22 is installed on the support 1 and is located below the upper mold 21 . The upper mold 21 is provided with a connected upper cavity and an upper relief cavity, and the lower mold 22 is provided with a lower cavity 32 and a lower relief cavity 31, and the lower cavity 32 and the upper cavity are combined into a cable for placing cables. The injection molding cavity, the lower relief cavity 31 and the upper relief cavity are combined into a placement cavity for placing the terminal holder 5. The terminal holder 5 is provided with an insertion hole 51 for inserting a plug terminal, and the insertion...

Embodiment 2

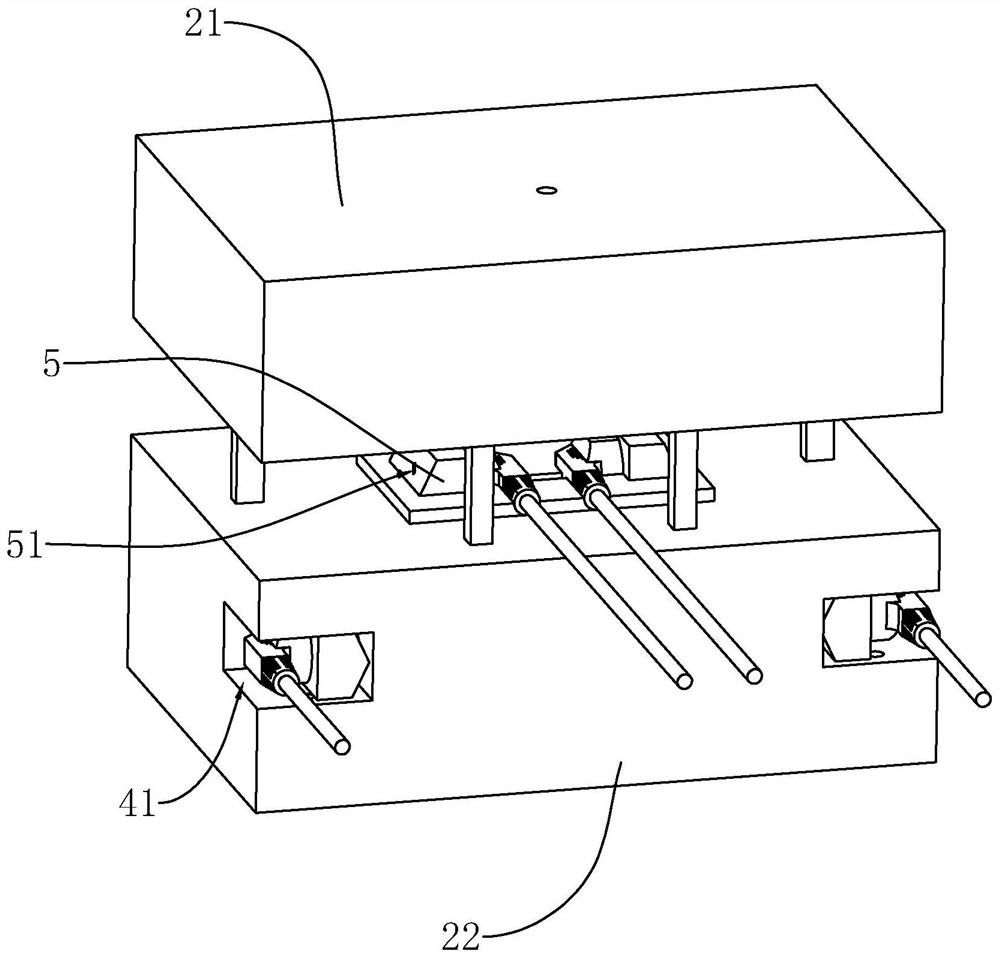

[0040] refer to image 3 and Figure 4The difference between this embodiment and Embodiment 1 is that the lower mold 22 is provided with a positioning cavity 41, a sliding cavity 421, a lift hole 422 and an extension hole 43, and the sliding cavity 421 and the positioning cavity 41 pass through the extension hole 43 The lifting hole 422 communicates with the sliding cavity 421 and communicates with the outside world. The positioning cavity 41 is used for placing the terminal holder 5 .

[0041] refer to Figure 4 and Figure 5 The lower mold 22 is also provided with an ejector plate 64 and a sliding mechanism for sliding the ejector plate 64. The sliding mechanism includes a lifting rod 61, a sliding rod 62 and an abutment assembly, and the abutment assembly includes a fixed plate 63 and an abutment assembly. Connect spring 65. The lifting rod 61 is fixedly connected to the upper mold 21 and can extend into the sliding cavity 421 through the lifting hole 422 . One side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com