Building waterproof roll

A technology for building waterproofing and coiled materials, applied in chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve the problems of poor tensile strength of coiled materials and poor wear resistance of waterproof layer, and achieve tensile strength. High, increase wear resistance, increase practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

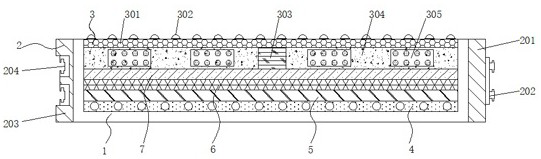

[0028] Example 1: See Figure 1-5 , a building waterproof coiled material, comprising a coiled material body 1, a firm structure 3 is arranged at the top inside the coiled material body 1, splicing structures 2 are arranged on both sides of the coiled material body 1, and a bottom end inside the coiled material body 1 is provided with Tensile structure;

[0029] see Figure 1-5 , a building waterproof coiled material also includes a tensile structure, the tensile structure includes a protective layer 4, the protective layer 4 is fixedly connected to the bottom end of the main body of the coiled material 1, the top of the protective layer 4 is fixedly connected to a waterproof layer 5, and the waterproof layer 5 and the protective layer 4 are connected by an adhesive, the material of the waterproof layer 5 is polyethylene polypropylene fiber, the top of the waterproof layer 5 is fixedly connected with a reinforcement layer 6, and the top of the reinforcement layer 6 is fixedly...

Embodiment 2

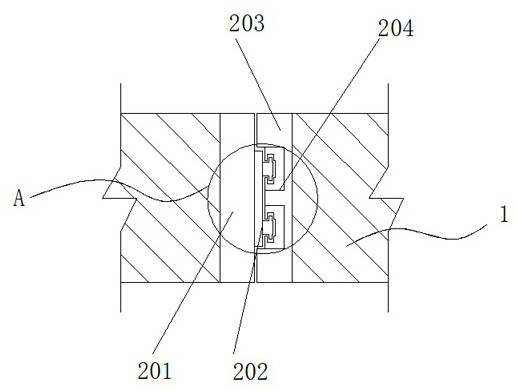

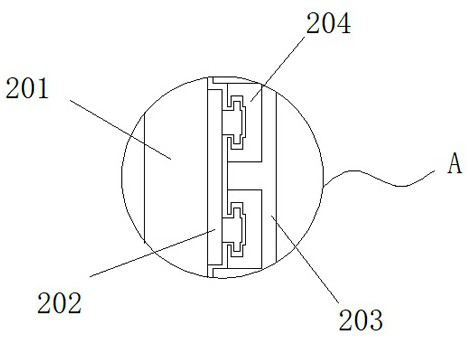

[0031] Embodiment 2: The splicing structure 2 is composed of a first connecting seat 201, a block 202, a second connecting seat 203 and a card slot 204. The first connecting seat 201 is fixedly connected to one side of the coil body 1. The first connecting seat 201 The outside of the card is fixedly connected with a block 202, the width of the outside of the block 202 is smaller than the width of the inside of the slot 204, the block 202 is embedded in the inside of the slot 204, and there is an engaging structure between the block 202 and the slot 204, the second The connecting seat 203 is fixedly connected to the other side of the coil body 1, and the second connecting seat 203 is fixedly connected with a card slot 204 inside;

[0032] Specifically, such as figure 1 , figure 2 and image 3 As shown, when the length of the main coil body 1 needs to be extended, the second connecting seat 203 of the previous piece is spliced together with the first connecting seat 201 of ...

Embodiment 3

[0033] Embodiment 3: The solid structure 3 is composed of a buffer pad 301, a bump 302, a partition 303, a sponge board 304 and waterproof particles 305. The sponge board 304 is fixedly connected to the top of the insulation cotton 7, and the middle position of the sponge board 304 is fixedly connected. There is a partition 303, the two sides of the sponge board 304 are fixedly connected with waterproof particles 305, the top of the sponge board 304 is fixedly connected with a buffer pad 301, and the upper surface of the buffer pad 301 is fixedly connected with a bump 302, and the bump 302 is provided with multiple group and arranged at equal intervals on the upper surface of the buffer pad 301;

[0034] Specifically, such as figure 1 and Figure 5 As shown, the outer surface of the bump 302 is in contact with the building and fit together, which increases the friction between the building and ensures the firmness of the fit, so that the coil main body 1 and the building are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com