Turnover device and method suitable for elastic deflection beam

A technology of elastic deflection and turning frame, which is applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems of beam structure size difference, failure to recover, beam deformation, etc., to reduce the difficulty of turning over, simple structure, Avoid the effect of shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

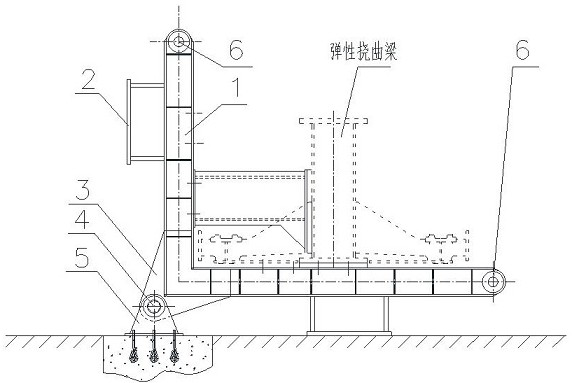

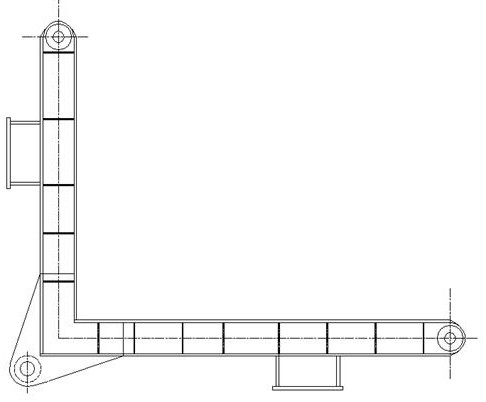

[0016] Example 1: refer to the attached Figure 1-8 . A turning device suitable for elastic flexural beams is composed of an L turning frame 1, a supporting pier 2, an anchoring pin shaft lug 3, an anchoring pin shaft 4, and a fixed seat 5. The anchoring pin shaft lug 3 and the L turning frame are composed of 1 is connected at the root, the anchor pin 3 is hinged to the fixed seat 5 through the anchor pin 4, the fixed seat 5 is fixed on the ground as a fixed rotation point, and the support pier 2 is connected to the frame body of the L turning frame respectively. The two connecting ends of the L turning frame are respectively hoisting holes 6 .

Embodiment 2

[0017] Example 2: On the basis of Example 1, a method for turning over an elastically deflected beam, one lifting point of the hoisting device is connected to the first hoisting hole 6 in the L turning frame 1, and another lifting point of the hoisting device and The second hoisting hole 6 in the L turning frame 1 is connected. Through the action of the lifting equipment, the first hoisting hole 6 is raised sideways, and the second hoisting hole 6 is sidely lowered to realize the beam body 90 0 Turn over, and then be supported by the support pier 2 on the L turning frame; change the position of the turning device, the first hoisting hole 6 side in the L turning frame 1 descends, the second hoisting hole 6 side rises, the L turning frame is turned in place, and then the Supported by the support pier 2 on the L turning frame.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com