Anti-falling device for bedplate of leather vacuum drying machine

A vacuum dryer and anti-drop technology, which is applied in leather drying, small raw hide/big raw hide/leather/fur mechanical treatment, raw hide/leather/fur manufacturing equipment, etc., can solve the hidden dangers of staff safety, staff injuries, Avoid problems such as the board is easy to fall, so as to improve safety, avoid accidents and prevent falls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016]Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

[0017]BRIEF DESCRIPTION OF THE INVENTION OF THE INVENTION The different types of cross-sectional lines in the figure are not marked in accordance with national standards, nor do not require the material of the components, and is a cross-sectional view of the elements in the figure.

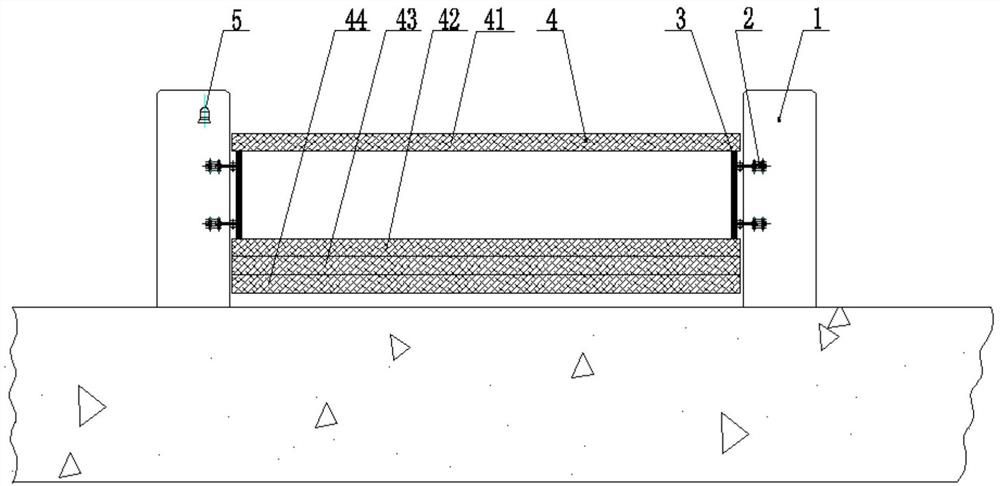

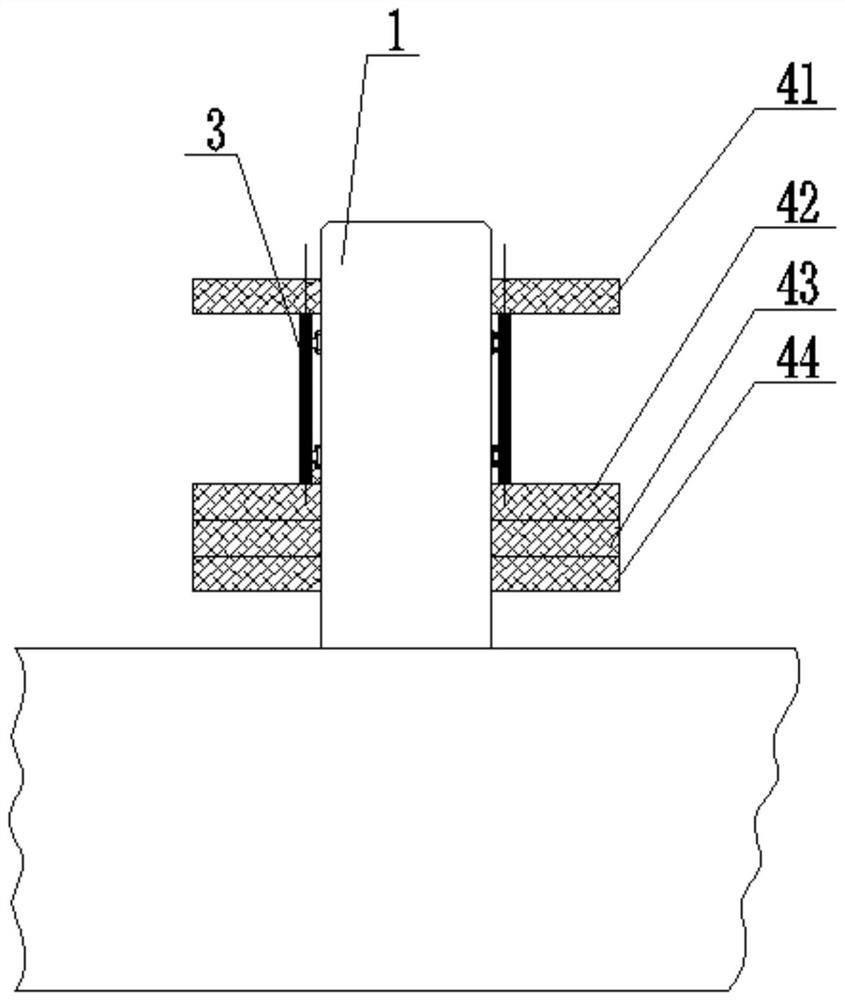

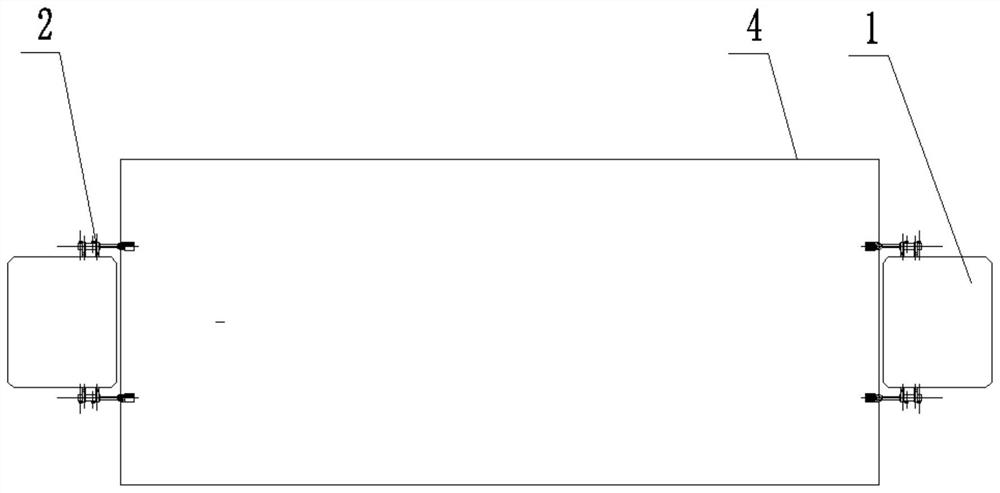

[0018]SeeFigure 1-4A leather vacuum dryer platen falling device, including a platen 4, and both ends of the plate 4 are provided with a column 1, and the platen 4 is from the first plate 41, the second board 42, The third plate 43 and the fourth board 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com