Compact pintle injector adjusting mechanism

A technology of adjusting mechanism and injector, which is applied to machines/engines, aerospace vehicles, aircrafts, etc., can solve the problems of large volume, many parts, and reduce the reliability of rocket engine systems, and achieve the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

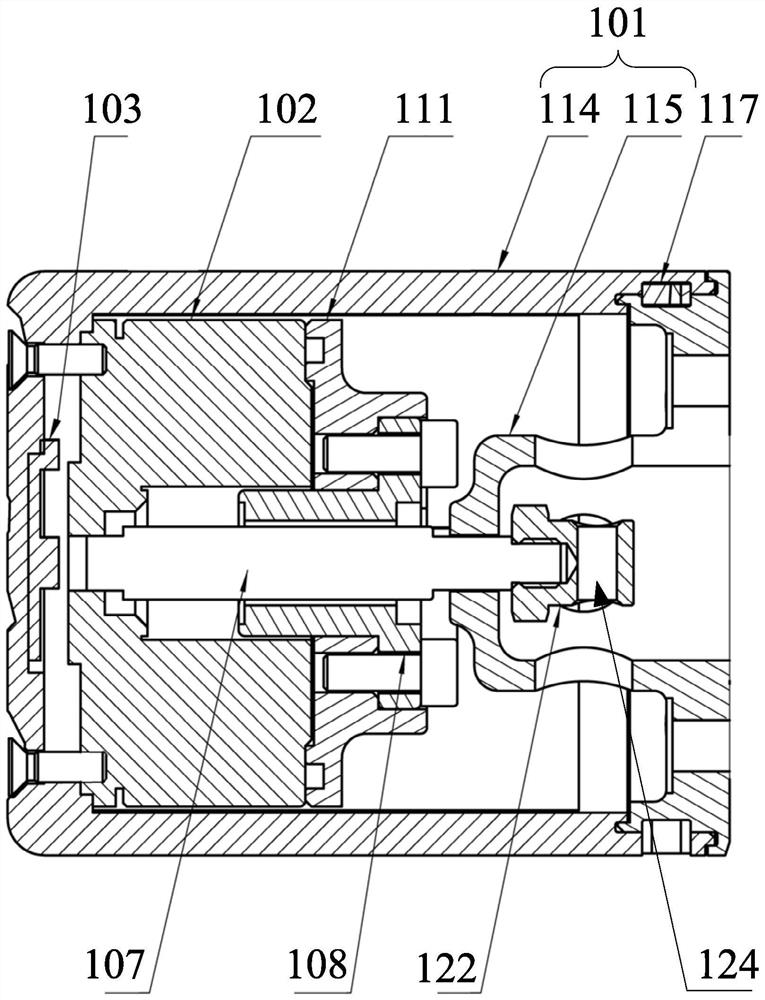

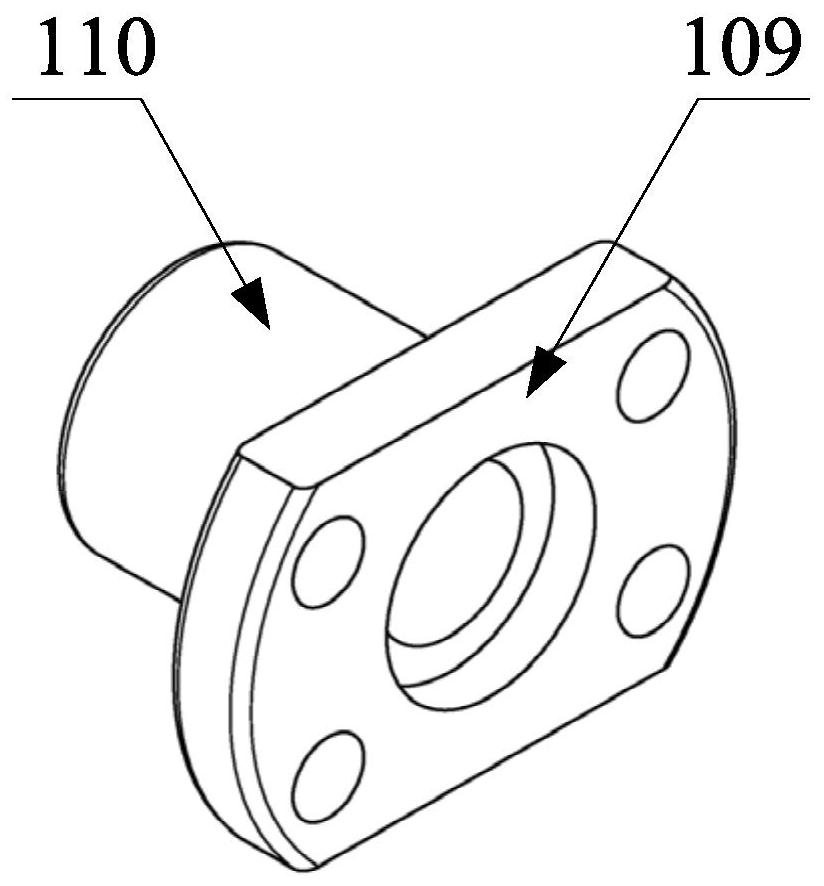

[0050] see Figure 1 to Figure 6As shown, the compact pintle injector adjustment mechanism provided by the present application includes a fixed frame 101 , a through-hole servo motor 102 and a transmission assembly. The end of the fixed frame 101 is connected to the head of the pintle injector, and the through-hole servo motor 102 and the transmission assembly are installed in the fixed frame 101; the fixed frame 101 forms a main support structure for fixing the through-hole servo motor 102 And the transmission assembly, and accommodate them both to make the structure more compact.

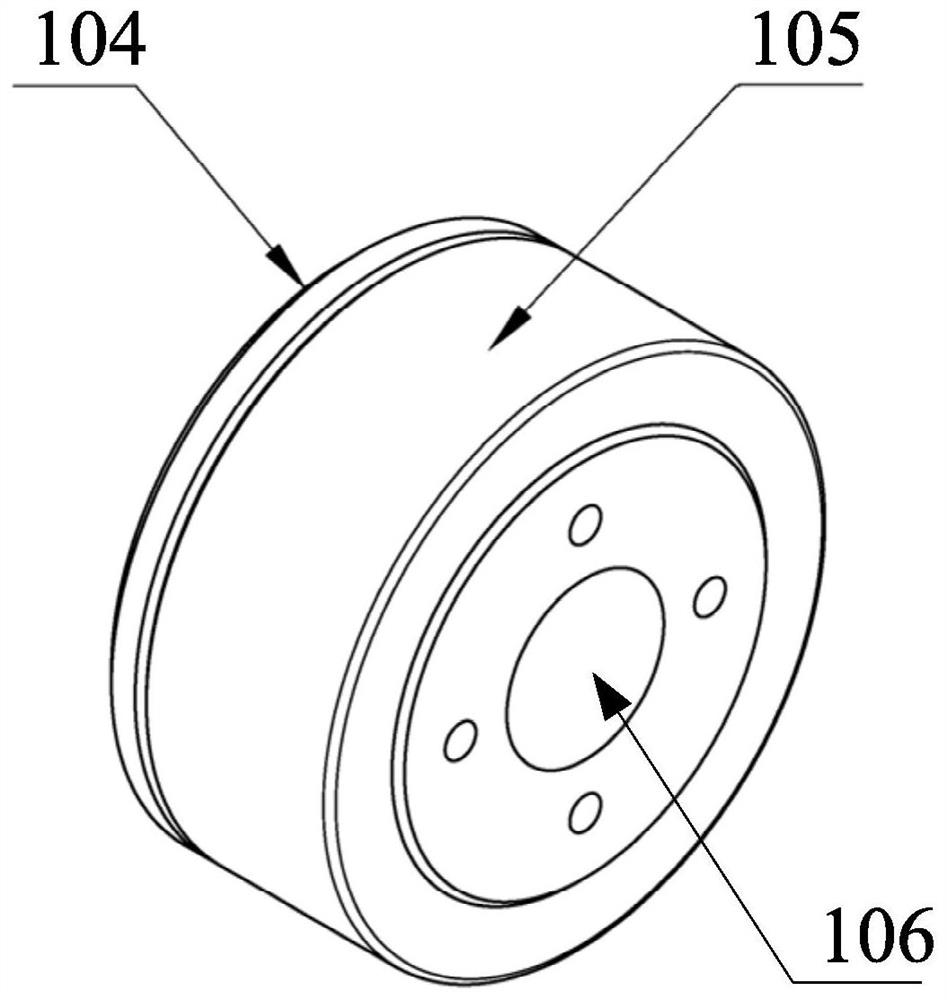

[0051] The stator 104 of the through-hole servo motor 102 is connected to the fixed frame 101, that is, the motor is installed on the fixed frame 101; the rotor 105 of the through-hole servo motor 102 is connected to the transmission assembly, and the transmission assembly is used to output the through-hole servo motor 102 The rotary motion of the pintle injector is converted into linear motion, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com