A mixed flow fan

A mixed-flow fan and liquid storage chamber technology, which is applied in mechanical equipment, electromechanical devices, machines/engines, etc., can solve the problems of shortening the service life of the motor, slow heating of the coolant, and reducing the cooling effect of the motor, so as to improve the use environment and improve the protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

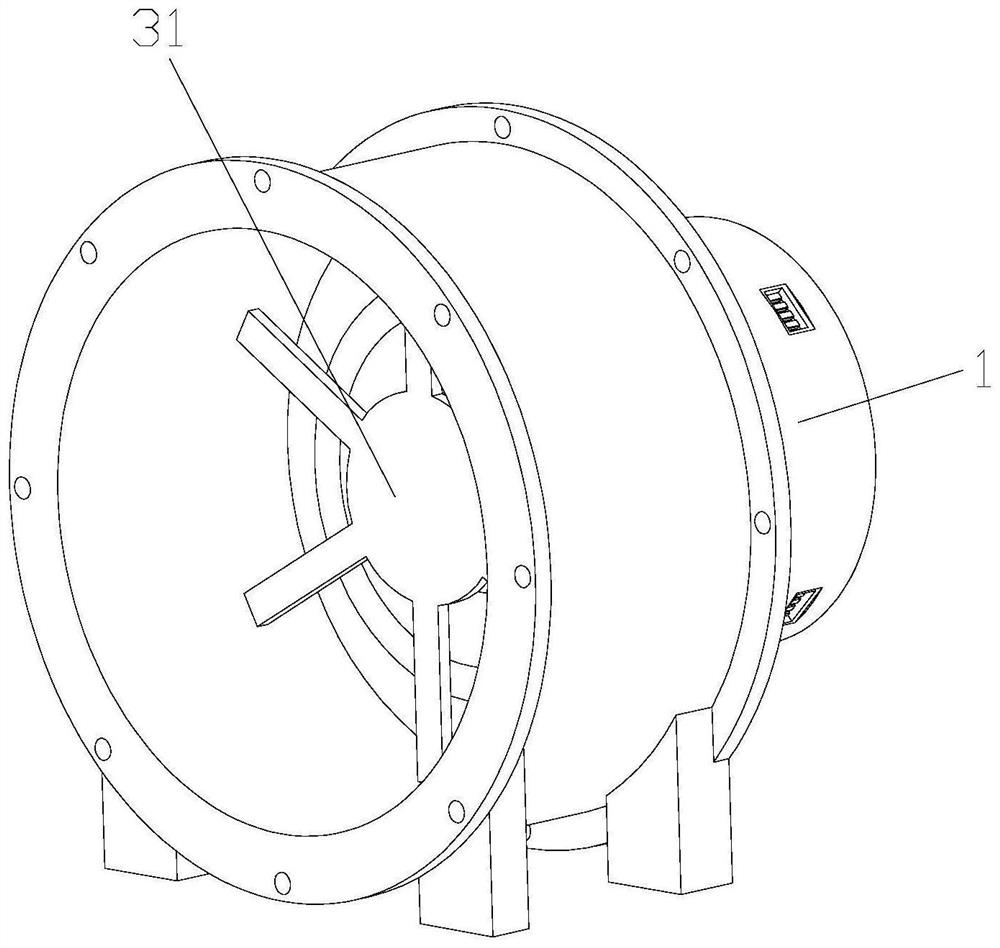

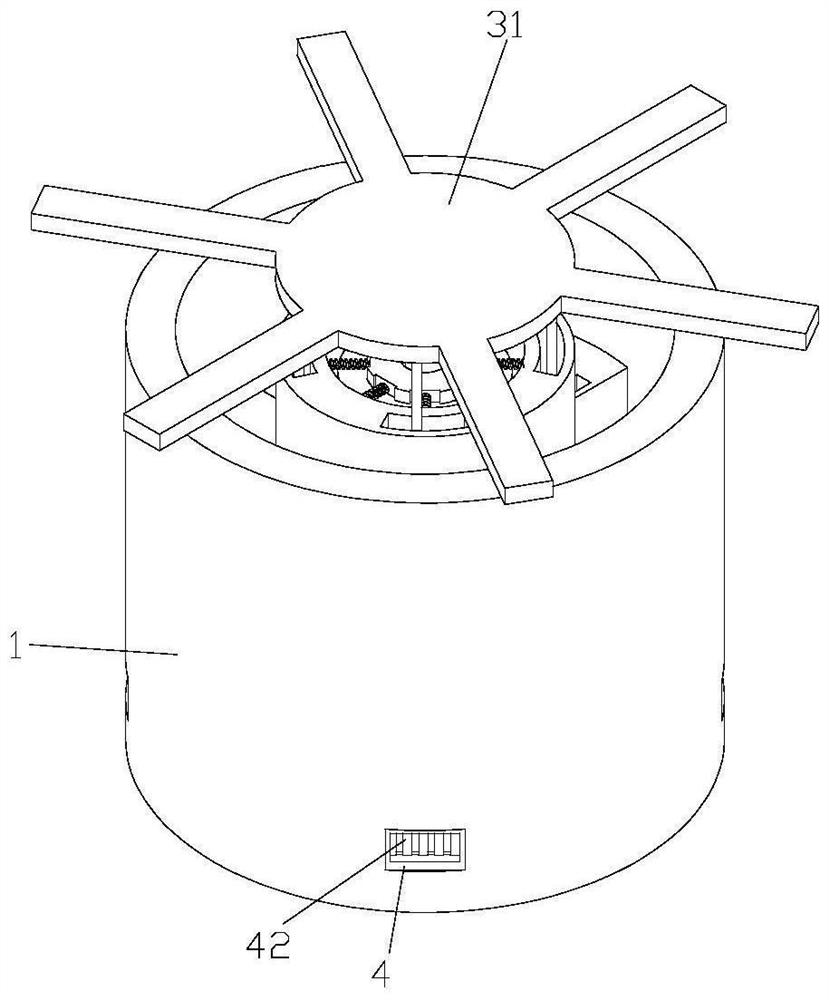

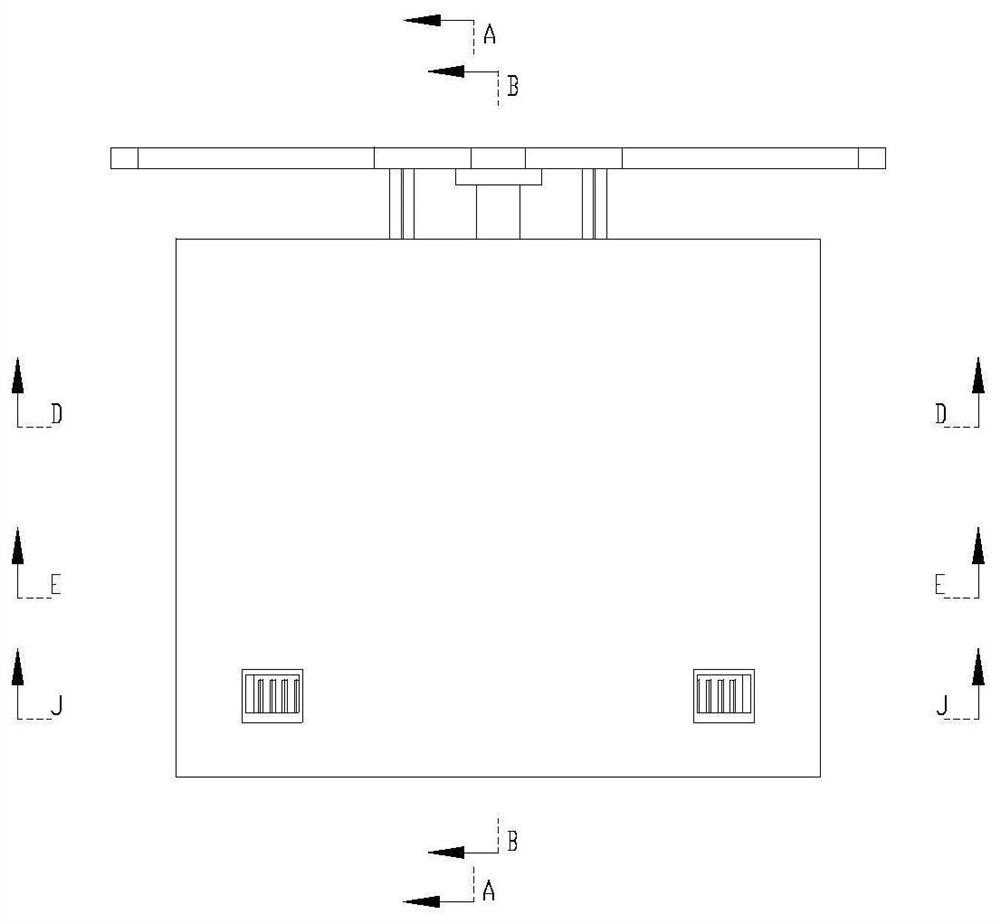

[0042] like Figure 1-24 As shown, a mixed-flow fan includes a casing 1, a motor 3 disposed in the casing 1, and a first fan 31 disposed on the output shaft of the motor 3. The casing 1 is provided with a first fan 31. The connection block 24, the first connection block 24 is provided with a fixing ring 2, the motor 3 is arranged in the fixing ring 2, the top of the fixing ring 2 is provided with a first fixing plate 21, the first fixing A plurality of first fixing springs 211 are arranged on the side wall of the plate 21, a second fixing plate 22 is arranged at the bottom of the fixing ring 2, and a plurality of second fixing springs 221 are arranged on the side wall of the second fixing plate 22; The casing 1 is provided with a first liquid storage cavity, the fixing ring 2 is provided with a second liquid storage cavity, and the first liquid storage cavity is filled with cooling liquid. When the fan is working, the first liquid storage cavity is The cooling liquid in the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com