A method for reducing moisture loss during vacuum precooling of rice

A vacuum and rice technology, applied in the direction of food ingredients as color, food science, etc., can solve the problems of increasing the risk of microbial contamination, uneven distribution of rice moisture, affecting quality, etc., to avoid the deterioration of rice quality, and to improve the vacuum pre-cooling effect. , the effect of reducing the effect of color and lustre

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

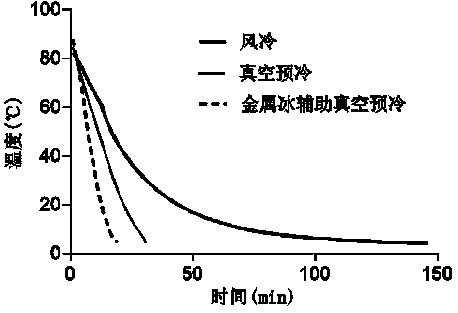

Method used

Image

Examples

Embodiment 1

[0030] (1) Cook the mixture of rice and water (the weight ratio of rice and water is 1:1.5), and control the weight of the mixture and the size of the container so that the height of the cooked rice is 200mm, and the length and width are both 1000mm. The time is half an hour, and the cooking method is steam cooking.

[0031] (2) Metal ice needs to be cleaned with tap water first, and then placed in a cold storage at -18±2°C for 2 to 3 hours (satisfied that the temperature of the refrigerant reaches -5±2°C), and then sterilized with 75% alcohol for 1 minute , and then rinse with tap water at 4±1°C for 2 minutes. Wherein, the composition ratio of the brine in the metal ice in specific embodiment 1 is 12.5% sodium chloride, 85.5% water and 2% sodium alginate. The weight ratio of metal ice to rice is 2.5:1. At the same time, the operating conditions of the "metal ice assisted vacuum precooling" in Examples 2 and 3 are the same as the operating conditions of the "metal ice assi...

Embodiment 2

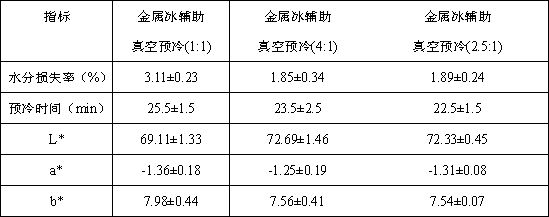

[0045] The operation method of embodiment 2 is the same as that of embodiment 1, the difference is the amount of metal ice added, in order to form a comparison and determine the best ratio, we have selected the weight ratio of metal ice and rice to be 1:1 and 4:1 respectively For comparison, the results are shown in Table 3: Although the addition of metal ice can effectively improve the water loss and reduce the pre-cooling time, the more the better, when the increase reaches 4:1, it may be due to gravity. Slightly increased cooldown time. Of course, it is well known that the increase of metal ice will also increase the corresponding cost. The above results show that the selected specific weight ratio of metal ice and rice in the patent scope can effectively reduce the water loss rate of rice, pre-cooling time and color influence. Among them, the proportion range of metal ice-borne refrigerant is 12.5% sodium chloride, 85.5% water and 2% sodium alginate.

[0046] Table 3 E...

Embodiment 3

[0050] The operation method of embodiment 3 is the same as that of embodiment 1, but the difference is the brine in the metal ice. In order to form a comparison, we have selected various ratios of brine for comparison, such as I, II, and IV in Table 4 and V, while 12.5% sodium chloride, 85.5% water and 2% sodium alginate (III) were used in this example. The results are shown in Table 4: Different refrigerants will also lead to differences between the results. From the data results in Table 4, it can be speculated that too high or too low sodium alginate and sodium chloride content will lead to parameters in the rice pre-cooling process. and color changes. The ratio of brine III in metal ice has a lower water loss rate and precooling time than other brines, and there is no significant difference in other indicators such as color. The above results show that the specific composition ratio of brine selected in the scope of the patent rights can effectively reduce the water los...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com