An improved vacuum pre-cooling method for bayberry

A processing method and pre-cooling technology, which is applied in the fields of freezing/cold preservation of fruits/vegetables, food science, fruit and vegetable preservation, etc., can solve the problem of inability to complete the temperature drop of bayberry, hinder the outward diffusion of bayberry water, and slow the rate of temperature drop of bayberry To improve energy efficiency, avoid quality deterioration, and facilitate operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

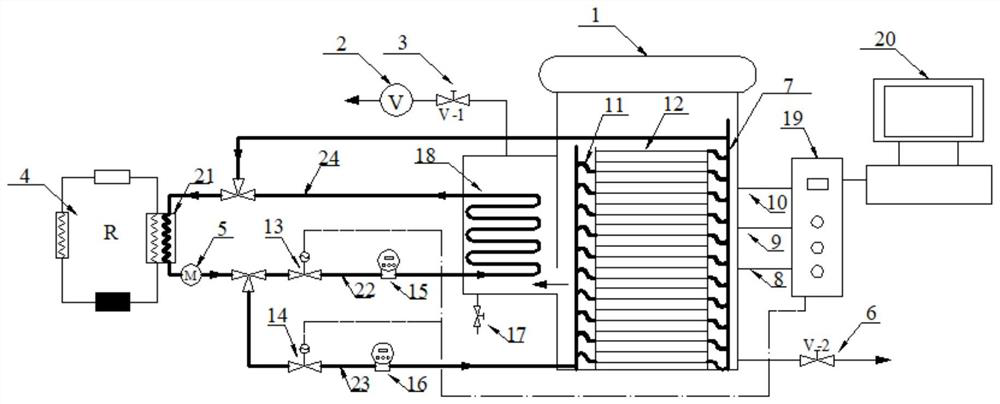

[0035]The auxiliary device group 7 involved in the present invention is used together with the vacuum precooling combination for the precooling of red bayberry. Among them, the vacuum pre-cooler includes a condensing system, a vacuum system, a data collection system, and a data processing and operating system, which are connected in sequence, including a refrigeration unit 4, a condenser 18, a cryogenic liquid circulation pump 5, a heat exchanger 21, and branch pipelines Ⅰ22, electric valve 13, flow meter 15, branch pipe Ⅱ23, electric valve 14, flow meter 16 and hose 14, vacuum box 1, vacuum pump 2, pneumatic valve 3, exhaust valve 6, drain valve 17, weight sensor 8, pressure Sensor 9 and temperature sensor 10, data processor 19 and computer 20; the condensing system is composed of refrigeration unit 4, cryogenic liquid circulation pump 5, branch pipeline cooling capacity ①, branch pipeline cooling capacity ②; branch pipeline cooling capacity ① is composed of condenser 18. The...

Embodiment 2

[0041] (1) The freshly picked Dongkui bayberry should be sent to the laboratory immediately, and the time should not exceed 2 hours. Through the pretreatment of the harvested red bayberry, select the red bayberry with a darker color, no peculiar smell, a complete sample, a diameter of 45±2mm, no juice, and no damage.

[0042] (2) Auxiliary device group 7 is first cleaned with tap water, then sterilized with 75% low-temperature alcohol, rinsed with tap water at 4±1°C for 2 minutes, and then connected to branch pipeline II23.

[0043] (3) Before vacuum precooling, turn on the refrigeration unit 4, the cryogenic liquid circulation pump 5 and the electric valves 13 and 14, and lower the temperature of the auxiliary device group 7 and the condenser 18 to the set temperature -2 through the heat exchanger 21 ±2°C.

[0044] (4) Maintain the temperature of the main pipe 24 at -2±2°C, and control the pipeline flow rate at 35L / min.

[0045] (5) When the temperature of the auxiliary dev...

Embodiment 3

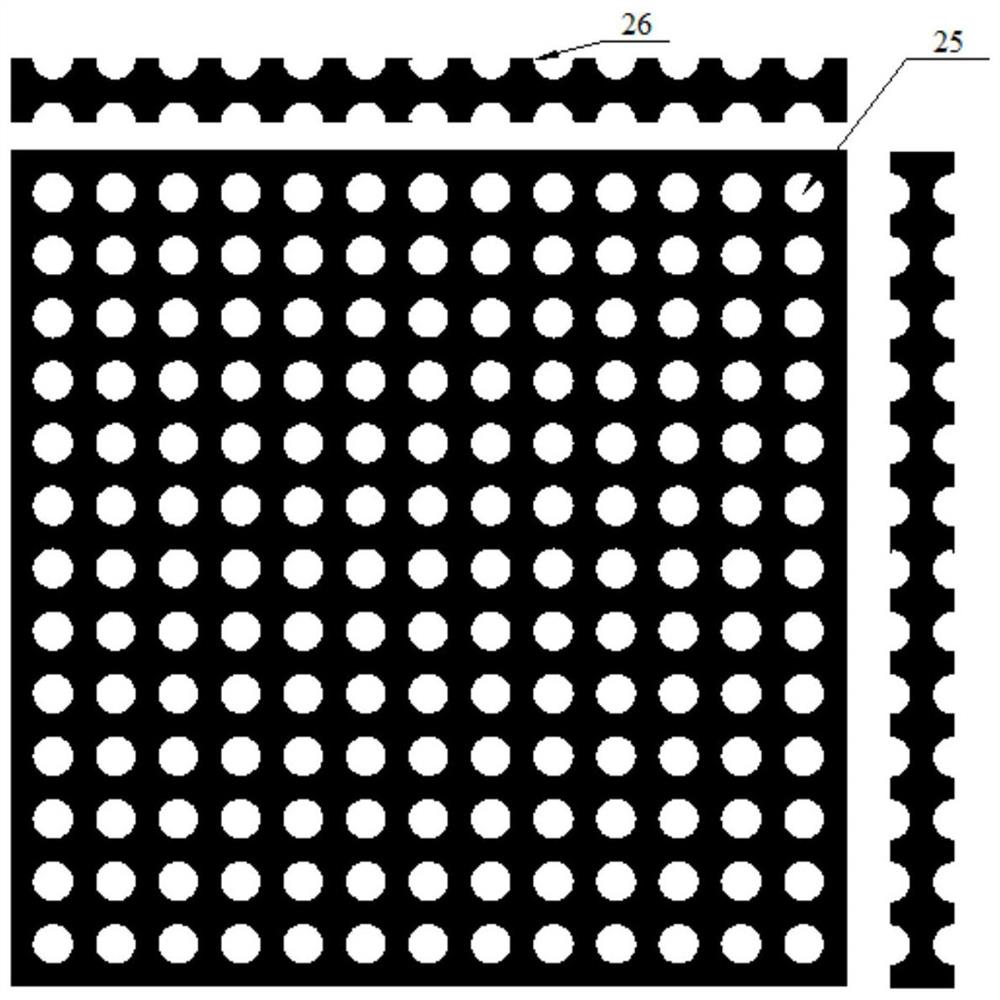

[0066] Embodiment 3 is the same as embodiment 1 method of operation, and the difference is that the device is different. The device used in embodiment 3 is different from the device in embodiment 1 in that the distance between the hemispherical groove 25 on the hollow cuboid 26 is different. Embodiment 3 The selected ones are spacings of 10mm and 40mm respectively. Other parameters include the diameter of the hemispherical groove 25 and the height of the hollow cuboid 26. The results obtained after precooling are as follows:

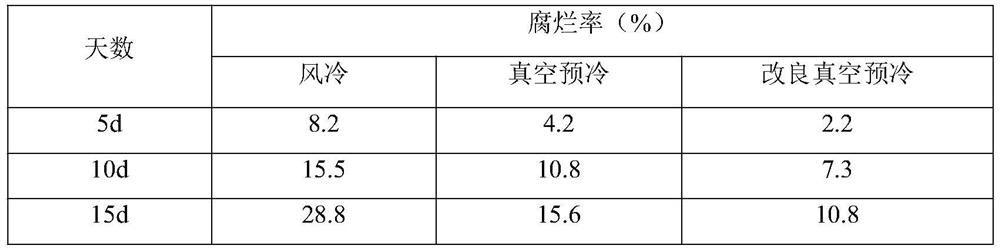

[0067] Table 4 Effects of different vacuum precooling methods on parameters in the precooling process of bayberry

[0068]

[0069] Table 4 is the impact of different device-assisted vacuum precooling modes on the red bayberry precooling process, and the results show that the number of embedded hemispherical grooves 25 on the hollow cuboid 26 is too much or too little (not within the scope of this patent claim) all have a negative impact on the red bay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com