Cryogenic treatment method for large-diameter cold-rolled work rolls and the cryogenic box used

A cold-rolled work roll and cryogenic treatment technology, used in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve the problems of low heat exchange efficiency, low work efficiency, slow cooling speed, etc., to achieve high thermal conductivity and improve work efficiency. , the effect of reducing the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

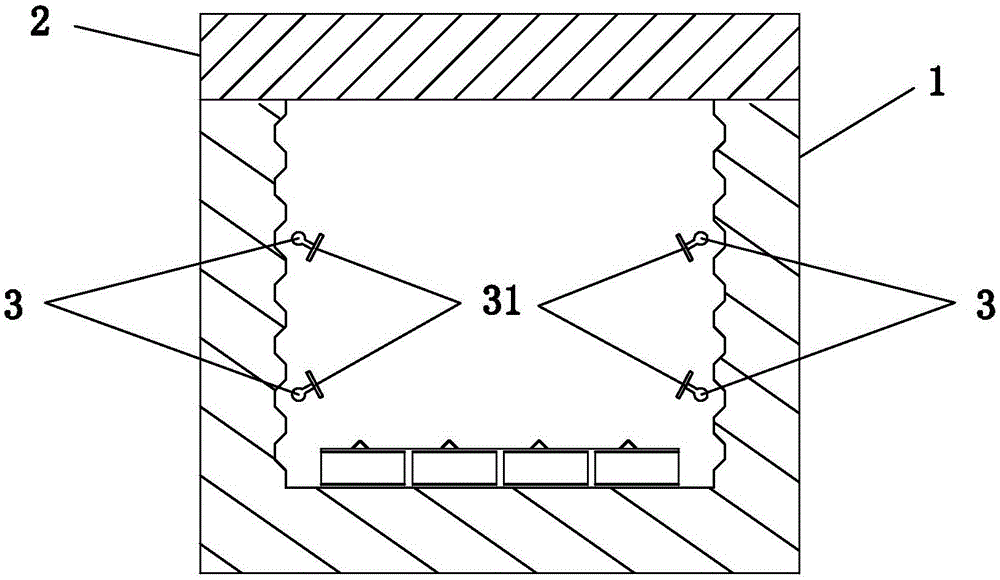

[0017] The cryogenic box used in the cryogenic treatment method of the large-diameter cold rolling work roll of this embodiment is shown in figure 1 , Which includes a box body 1 with a thermal insulation layer, a thermal insulation box cover 2 and a liquid nitrogen nozzle 3 arranged in the box body 1. There are two liquid nitrogen nozzles 3 up and down respectively, the upper 2 nozzles are inclined downward, the lower 2 nozzles are inclined upward, and the nozzle of each liquid nitrogen nozzle 3 is provided with a mesh cover 31.

[0018] Compared with the original cryogenic box, the internal structure, size and other components of this cryogenic box are basically the same. For example, the box 1 is also equipped with an exhaust hole, and the box 1 is also equipped with a temperature sensor and a liquid nitrogen nozzle. 3 It is connected to the liquid nitrogen storage tank through a pipeline, and the pipeline is equipped with an ultra-low temperature solenoid valve ( figure 1 No...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com