Method for reducing moisture losses of cooked rice in vacuum precooling course

A vacuum and rice technology, which is applied in the direction of food ingredients as color, food science, etc., can solve the problems of uneven moisture distribution of rice, increase the risk of microbial contamination, and affect quality, so as to inhibit the outward evaporation of water vapor and avoid secondary pollution , the effect of reducing the loss of water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Cook the mixture of rice and water (the weight ratio of rice and water is 1:1.5), and control the weight of the mixture and the size of the container so that the cooked rice has a height of 200mm, a length and a width of 1000mm, The cooking time is half an hour, and the cooking method is steam cooking.

[0030] (2) The edible water polo was prepared with the prepared sodium alginate solution and calcium lactate solution, and the prepared edible water polo was continued to be immersed in the calcium lactate solution for 12 hours to make it completely immobilized, and then the immobilized The water polo is frozen in a freezer at -18°C, so that micro-ice crystals of 1 to 2 mm are formed on the surface (in specific example 1, the mass fraction of sodium alginate solution is 2%, the mass fraction of calcium lactate solution is 0.67%, slightly frozen The weight ratio of edible water polo and rice is 1.5: 1, and the freezing time of slightly frozen edible water polo is 20m...

Embodiment 2

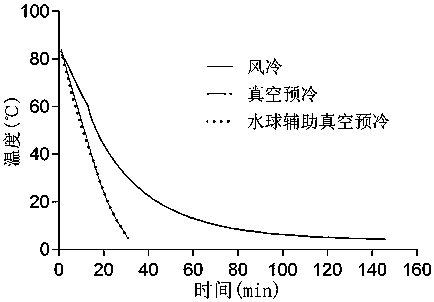

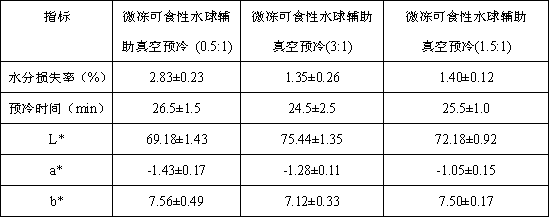

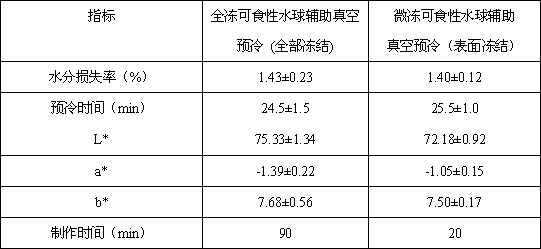

[0044] The operating method of embodiment 2 is identical with embodiment 1, and difference is the addition amount of slightly frozen edible water polo, in order to form a contrast and determine the best ratio, we have selected the ratio of slightly frozen edible water polo and rice to be respectively 0.5: 1 and 3:1 for comparison, the results are shown in Table 3: With the addition of slightly frozen edible water polo can effectively reduce water loss and pre-cooling time, but not as much as possible, when the increase reaches 3:1 At this time, although the ideal water loss value and pre-cooling time value are obtained, the color of the rice is very white when the color value L* is large, which is obviously different from the normal rice color operation. At the same time, the increase of slightly frozen edible water polo will also increase the corresponding cost. The above results show that the selected specific edible water polo and rice weight ratio in the patent scope can e...

Embodiment 3

[0049] Table 4 Effects of different ratios of sodium alginate and calcium lactate on water loss and color difference of rice (0±2°C, storage for 3 days)

[0050] index

Ⅰ

Ⅱ*

Ⅲ

Ⅳ

Ⅴ

1.83±0.23

/

1.40±0.12

1.56±0.35

2.43±0.19

Pre-cooling time (min)

51.5±5.5

/

25.5±1.0

49.5±1.5

24.5±1.5

L*

77.18±1.59

/

72.18±0.92

78.19±0.26

69.16±0.35

a*

-1.49±0.21

/

-1.05±0.15

-1.32±0.18

-1.21±0.33

b*

7.98±0.36

/

7.50±0.17

7.33±0.26

7.98±0.23

[0051] Ⅰ, Ⅱ, Ⅲ, Ⅳ, Ⅴ in the figure above. Among them Ⅰ: composition ratio of water polo (0.5% sodium alginate and 0.67% calcium lactate); Ⅱ: composition ratio of water polo (4% sodium alginate and 0.67% calcium lactate); Ⅲ: composition ratio of water polo (2% sodium alginate and 0.67% % calcium lactate); Ⅳ: composition ratio of water polo (2% sodium alginate and 0.17% calcium lactate); Ⅴ: composition r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com