Three-axis ball serving holder with connecting rod mechanism

A link mechanism and cloud platform technology, which is applied in the field of serving equipment, can solve the problems of inaccurate serving and unstable serving trajectory, and achieve the effect of light weight, small size, simple and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with specific embodiments.

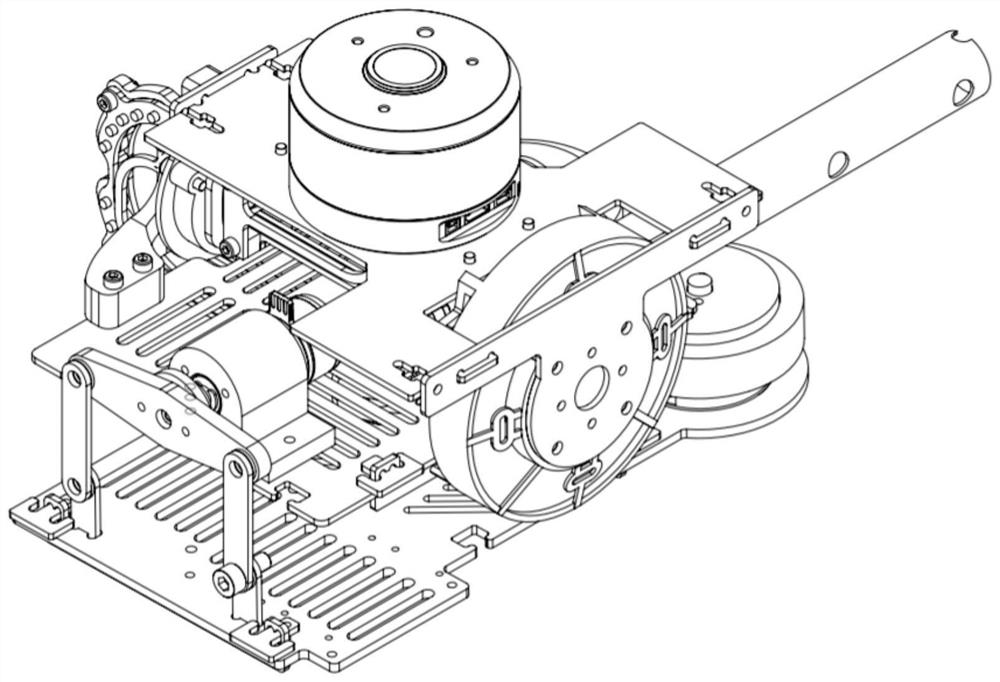

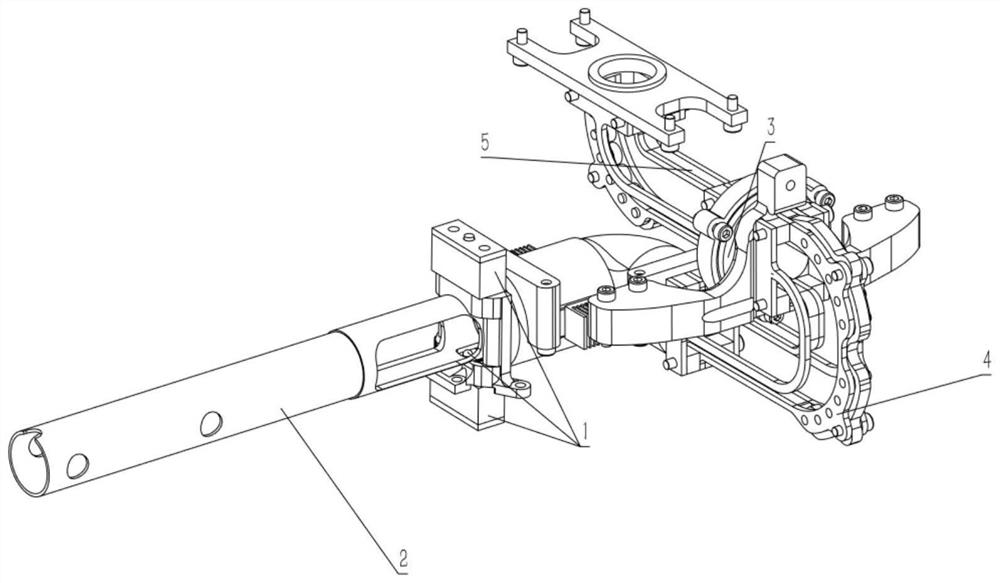

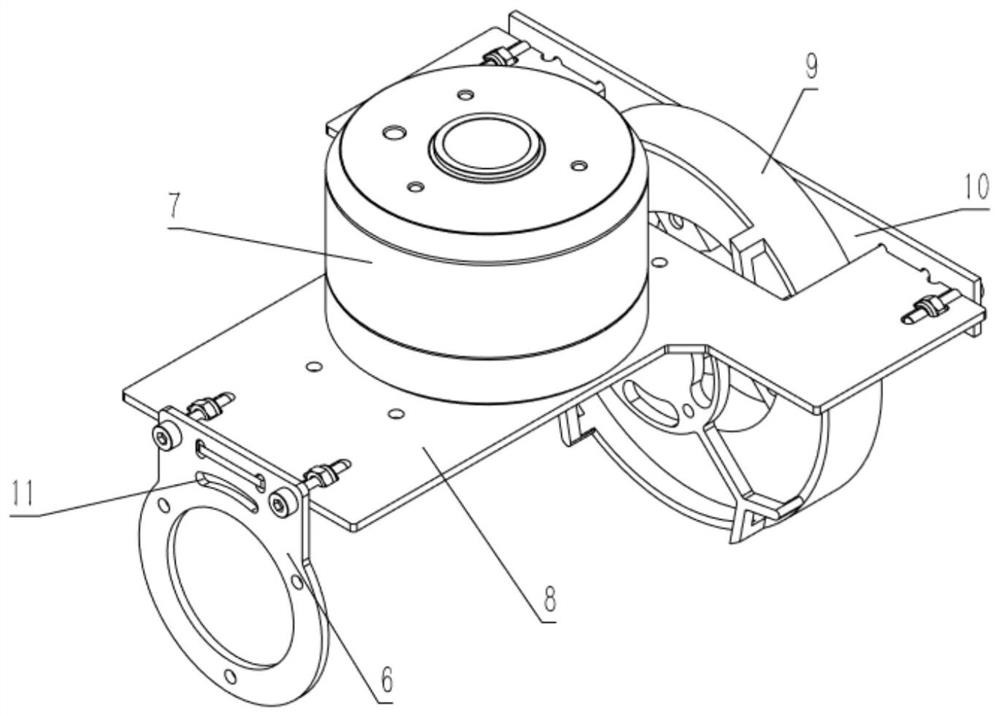

[0028] A three-axis ball head with a link mechanism, comprising a top part, a middle part, a launch part, a link mechanism, a middle motor 15, a top motor 9, and a steering motor 7 installed on a fixture;

[0029] The launching part includes the gun barrel 2, the middle layer motor is installed on the middle layer part, the middle layer motor is connected with the launching part through a linkage mechanism and drives the launching part to rotate around the axis of the gun barrel, the top layer motor is installed on the top layer part, and the top layer motor is connected with the middle layer part And drive the middle part to rotate around the first axis, the steering motor is connected with the top part and drives the top part to rotate around the vertical axis; the first axis is horizontal and perpendicular to the axis of the gun barrel.

[0030] The connecting ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap