Vortex refrigeration drain valve

A liquid discharge valve and eddy current technology, applied in the direction of dispersion particle separation, chemical instruments and methods, separation methods, etc., can solve the problems of poor separation efficiency, inability to adjust refrigeration temperature, and inability to realize automatic gas-liquid separation, etc., and achieve good sealing effect , Improve the effect of heat conduction ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

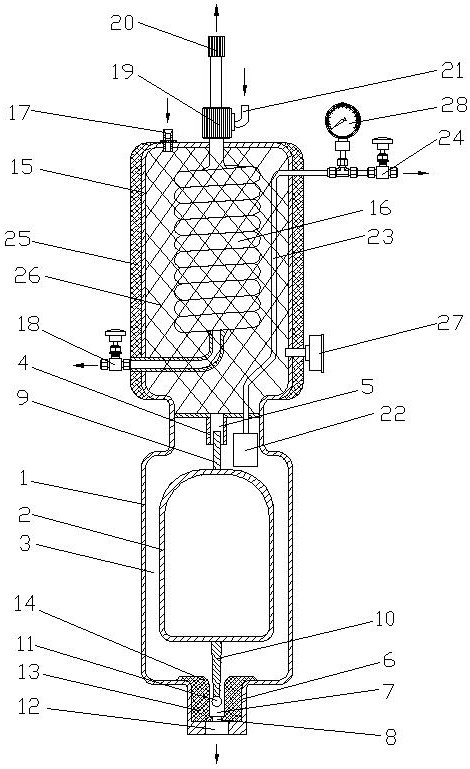

[0036] see figure 1 , a vortex refrigeration liquid discharge valve, including an outer cylinder 1, and also includes a refrigeration stainless steel cylinder 15, the refrigeration stainless steel cylinder 15 communicates with the outer cylinder 1, a stainless steel bellows 16 is arranged in the refrigeration stainless steel cylinder 15, and the refrigeration stainless steel cylinder 15 The upper part is connected with a stainless steel orifice inlet pipe 17 for the entry of pressurized sample gas, and the lower part of the refrigeration stainless steel cylinder 15 is connected with a first needle valve 18, which communicates with the lower end of the stainless steel bellows 16, and the stainless steel bellows The upper end of the pipe 16 runs through the refrigeration stainless steel cylinder 15, and the upper end of the stainless steel bellows 16 is connected with a vortex refrigerator 19 and a second needle valve 20, the vortex refrigerator 19 is connected with a compressed ...

Embodiment 2

[0039] see figure 1 , a vortex refrigeration liquid discharge valve, including an outer cylinder 1, and also includes a refrigeration stainless steel cylinder 15, the refrigeration stainless steel cylinder 15 communicates with the outer cylinder 1, a stainless steel bellows 16 is arranged in the refrigeration stainless steel cylinder 15, and the refrigeration stainless steel cylinder 15 The upper part is connected with a stainless steel orifice inlet pipe 17 for the entry of pressurized sample gas, and the lower part of the refrigeration stainless steel cylinder 15 is connected with a first needle valve 18, which communicates with the lower end of the stainless steel bellows 16, and the stainless steel bellows The upper end of the pipe 16 runs through the refrigeration stainless steel cylinder 15, and the upper end of the stainless steel bellows 16 is connected with a vortex refrigerator 19 and a second needle valve 20, the vortex refrigerator 19 is connected with a compressed ...

Embodiment 3

[0045] see figure 1, a vortex refrigeration liquid discharge valve, including an outer cylinder 1, and also includes a refrigeration stainless steel cylinder 15, the refrigeration stainless steel cylinder 15 communicates with the outer cylinder 1, a stainless steel bellows 16 is arranged in the refrigeration stainless steel cylinder 15, and the refrigeration stainless steel cylinder 15 The upper part is connected with a stainless steel orifice inlet pipe 17 for the entry of pressurized sample gas, and the lower part of the refrigeration stainless steel cylinder 15 is connected with a first needle valve 18, which communicates with the lower end of the stainless steel bellows 16, and the stainless steel bellows The upper end of the pipe 16 runs through the refrigeration stainless steel cylinder 15, and the upper end of the stainless steel bellows 16 is connected with a vortex refrigerator 19 and a second needle valve 20, the vortex refrigerator 19 is connected with a compressed g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com