Plate cleaning equipment

A technology for cleaning equipment and plates, which is applied in the direction of dust removal, cleaning methods and utensils, cleaning methods using tools, etc., and can solve problems such as unclean plate cleaning, a large amount of cleaning oil, and complicated processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

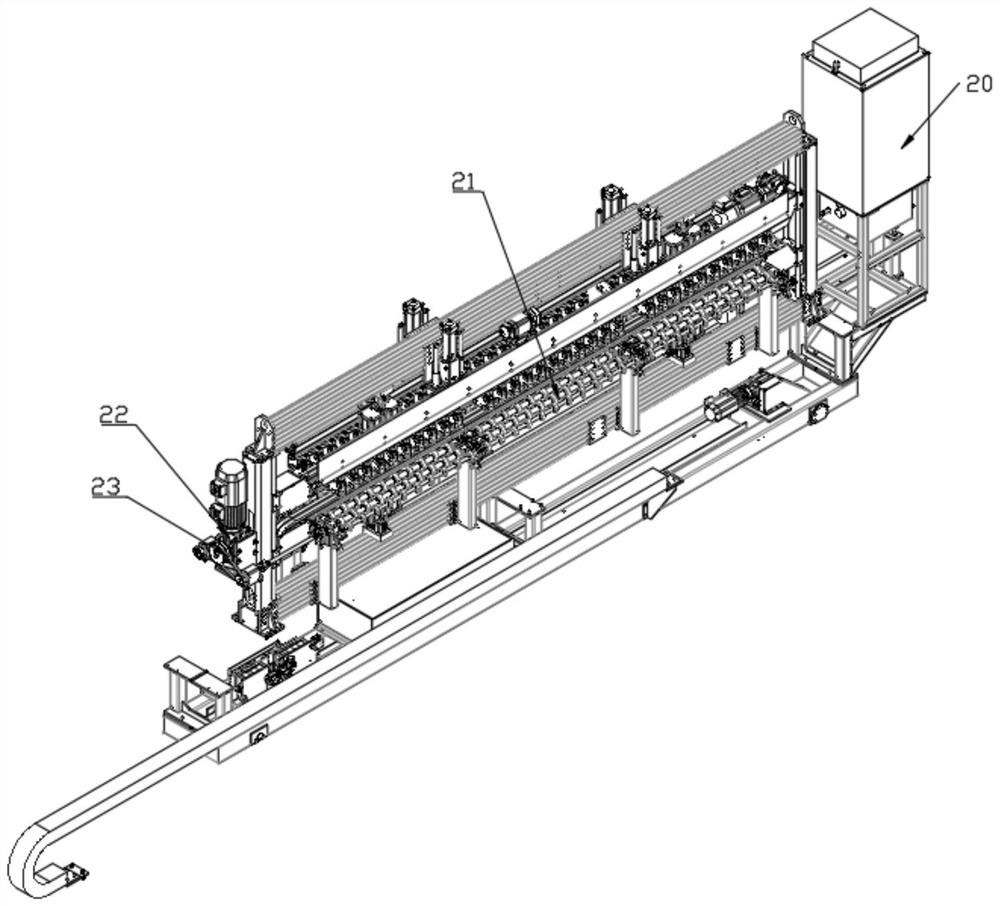

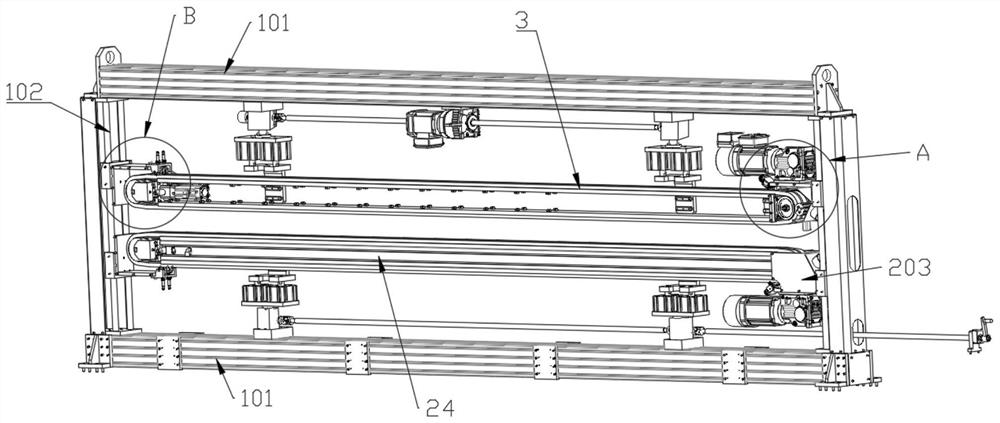

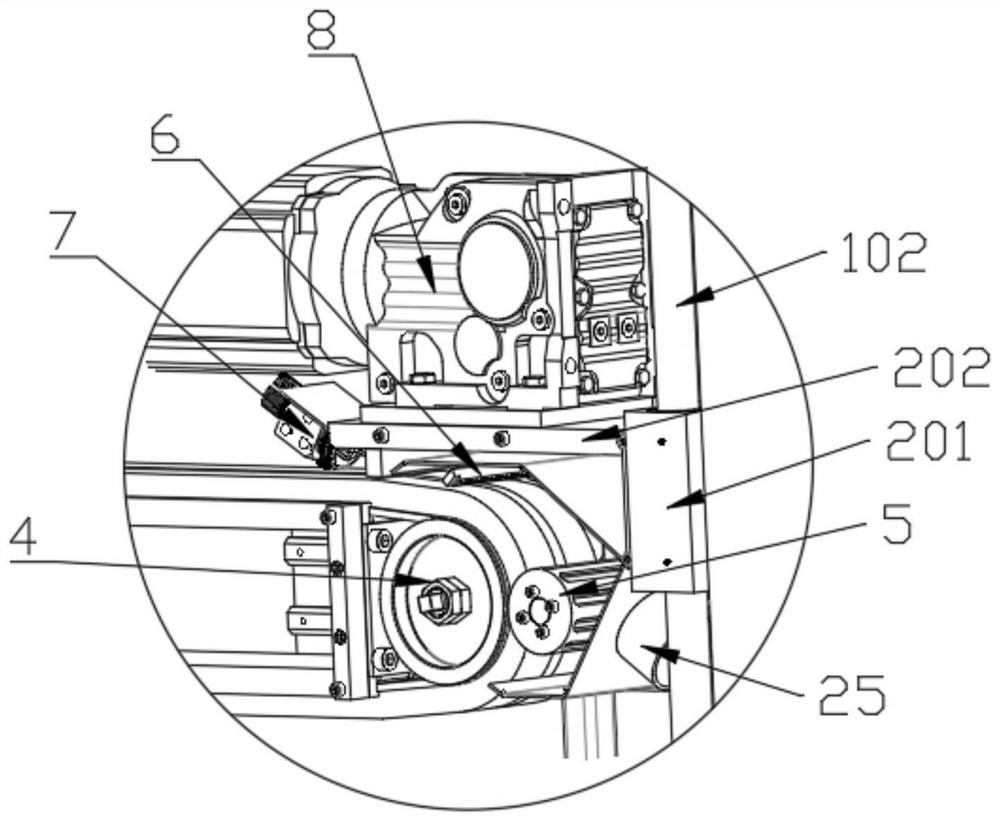

[0032] Such as Figure 1-Figure 6 The plate cleaning equipment shown includes a frame, and the frame includes two upper and lower beams 101, the left and right ends of the two beams 101 are supported by polished rods 102, and the polished rods 102 are provided with two sets of parallel corresponding support seats through linear bearing sliding , the support seat includes an L-shaped plate 202, a sliding seat 201, and two vertical plates 203 on the left and right. Fixed connection.

[0033] A belt roller 4 is provided between the two vertical plates 203 inside the support base, and a fixed plate 24 is provided between the two corresponding belt rollers 4 on the left and right sides. There are two brush belts 3 up and down, and the belt roller 4 on the right is provided with a brush driving mechanism 8 , and the brush driving mechanism 8 is fixed on the outer end surface of the L-shaped plate 202 .

[0034] The output end of the hairbrush driving mechanism 8 and the rotating s...

Embodiment 2

[0040] Such as Figure 1-Figure 6 The plate cleaning equipment shown includes a frame, and the frame includes two upper and lower beams 101, the left and right ends of the two beams 101 are supported by polished rods 102, and the polished rods 102 are provided with two sets of parallel corresponding support seats through linear bearing sliding , the support seat includes an L-shaped plate 202, a sliding seat 201, and two vertical plates 203 on the left and right. Fixed connection.

[0041] A belt roller 4 is provided between the two vertical plates 203 inside the support base, and a fixed plate 24 is provided between the two corresponding belt rollers 4 on the left and right sides. There are two brush belts 3 up and down, and the belt roller 4 on the right is provided with a brush driving mechanism 8 , and the brush driving mechanism 8 is fixed on the outer end surface of the L-shaped plate 202 .

[0042] The output end of the hairbrush driving mechanism 8 and the rotating s...

Embodiment 3

[0048] Such as Figure 1-Figure 6 The plate cleaning equipment shown includes a frame, and the frame includes two upper and lower beams 101, the left and right ends of the two beams 101 are supported by polished rods 102, and the polished rods 102 are provided with two sets of parallel corresponding support seats through linear bearing sliding , the support seat includes an L-shaped plate 202, a sliding seat 201, and two vertical plates 203 on the left and right. Fixed connection.

[0049] A belt roller 4 is provided between the two vertical plates 203 inside the support base, and a fixed plate 24 is provided between the two corresponding belt rollers 4 on the left and right sides. There are two brush belts 3 up and down, and the belt roller 4 on the right is provided with a brush driving mechanism 8 , and the brush driving mechanism 8 is fixed on the outer end surface of the L-shaped plate 202 .

[0050] The output end of the hairbrush driving mechanism 8 and the rotating s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com