Photoelectric module and method with dustproof assembly

A technology for optoelectronic modules and dust-proof components, which is applied in the directions of pollution prevention methods, cleaning methods and utensils, chemical instruments and methods, etc. To achieve the effect of satisfying heat dissipation and improving dustproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

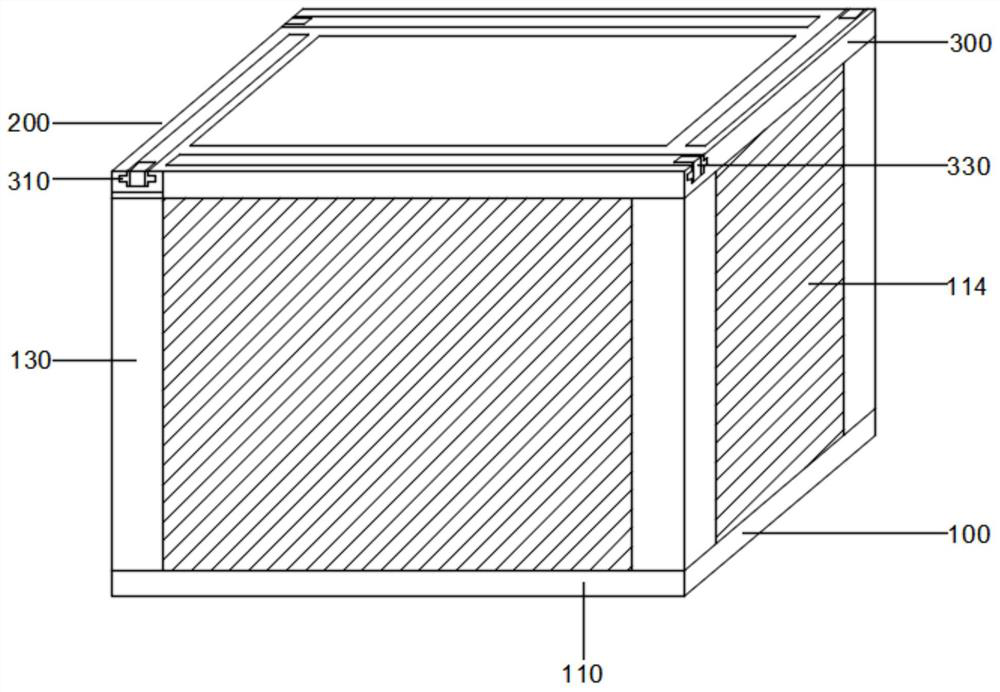

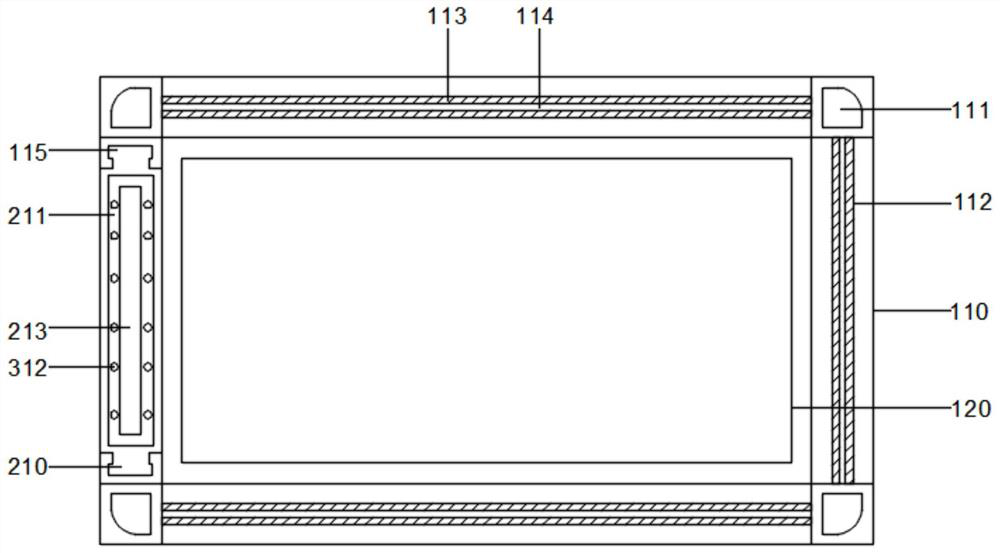

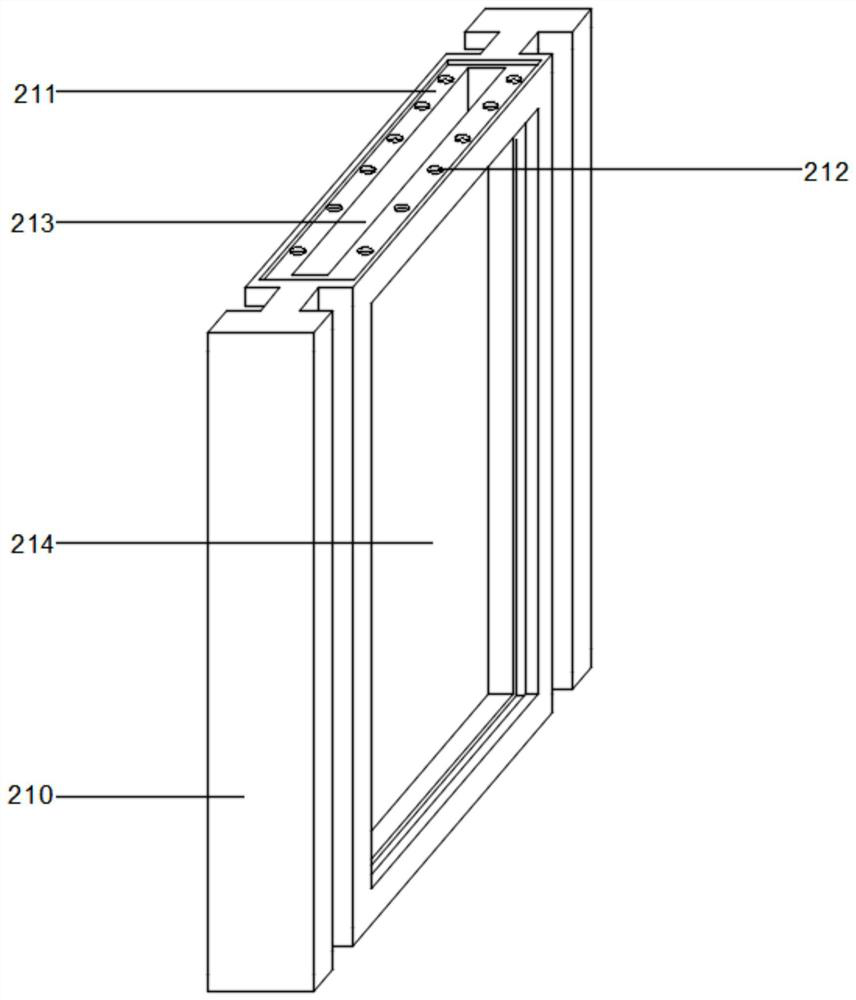

[0038] Refer to attached Figure 1-8 , the present invention provides a photoelectric module with a dust-proof component, including a base 100, a dust-proof and ventilating device 200, and a top cover 300. Specifically, the dust-proof and venting device 200 is fixedly installed on the top left side of the base 100, and the The top of the dust-proof and ventilating device 200 is provided with a top cover 300, the base 100 includes a bottom plate 110, the bottom of the bottom plate 110 is set as a rectangle, the four corners of the top of the bottom plate 110 are opened with column grooves 111, and the top of the bottom plate 110 is provided with side plate grooves 112, the side plate groove 112 is provided with three groups, the side plate groove 112 is located at the top of the front end, the rear end and the right side end of the bottom plate 110, the inner wall of the side plate groove 112 is provided with a gas phase silica gel gasket 113, the gas phase silica gel The gaske...

Embodiment 2

[0057] Refer to attached Figure 9 , the present invention provides a photoelectric module with a dust-proof component, including a gas-permeable film 224, and the dust-proof and ventilating device 200 also includes a gas-permeable film 224, and the gas-permeable film 224 is provided with two groups, and the gas-permeable film of the two groups 224 is fixedly installed on the inner wall of the T-shaped frame 221, and the material of the air-permeable membrane 224 is polytetrafluoroethylene. The air-permeable membrane 224 has the effects of air permeability, waterproof, dustproof, etc., and has a heat-absorbing effect, which is conducive to the heat dissipation of the photoelectric module 120;

[0058] A kind of photoelectric module method with dust-proof component, also comprise specific operation steps as follows;

[0059] Step 1: Install the photoelectric module 120 at a suitable position on the top of the bottom plate 110 in the clean room, then insert the column 130 into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com