Shaft expansion forming device

A molding device and expanding head technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve a lot of problems such as smoke and dust environment, pollution, etc., and achieve the effect of precise molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

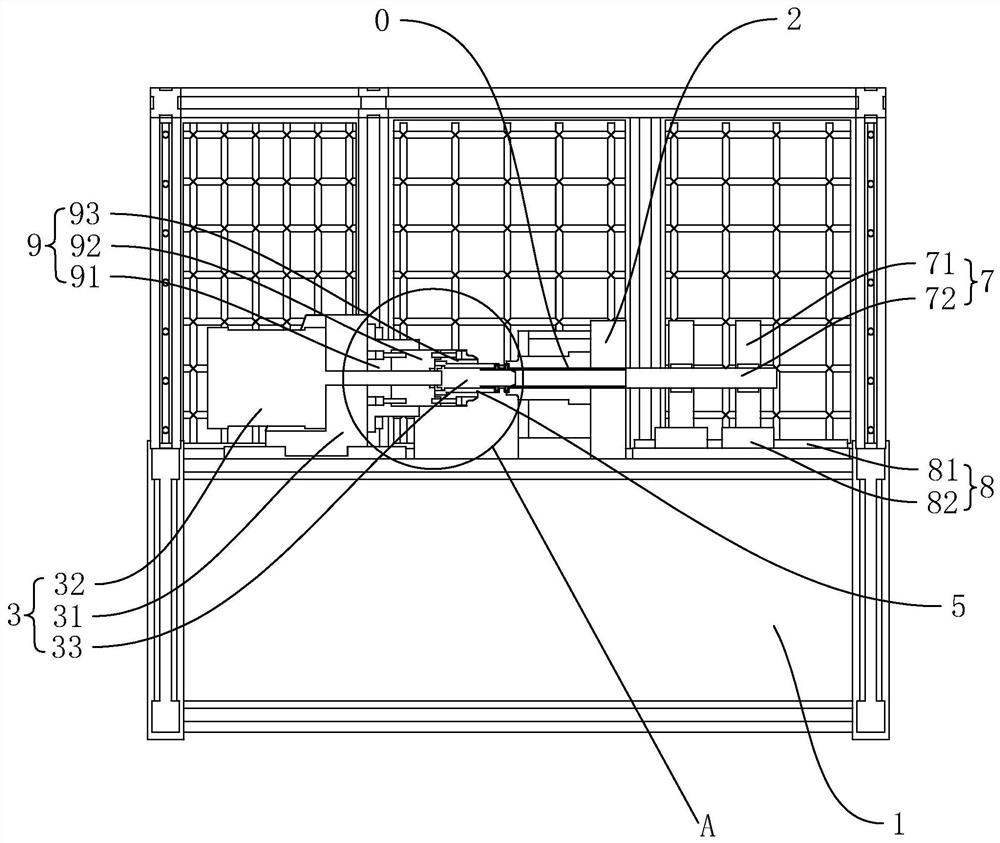

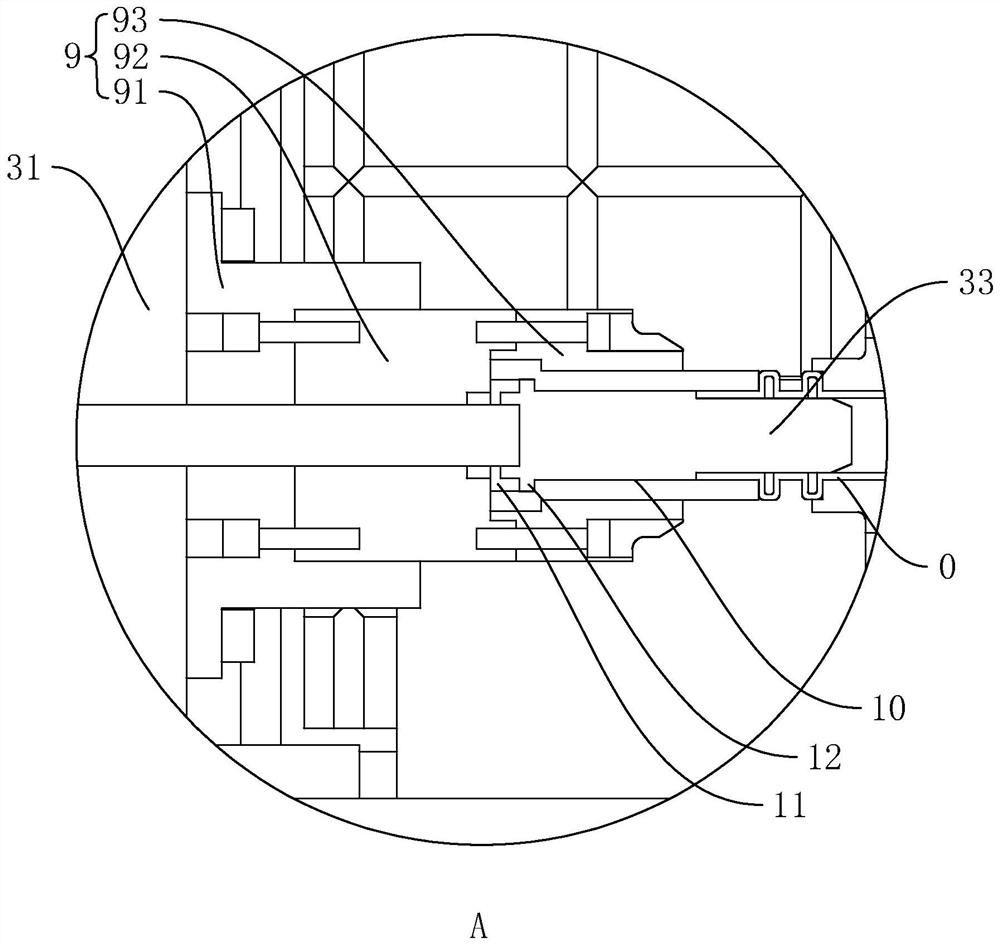

[0033] The following is attached Figure 2-4 The application is described in further detail.

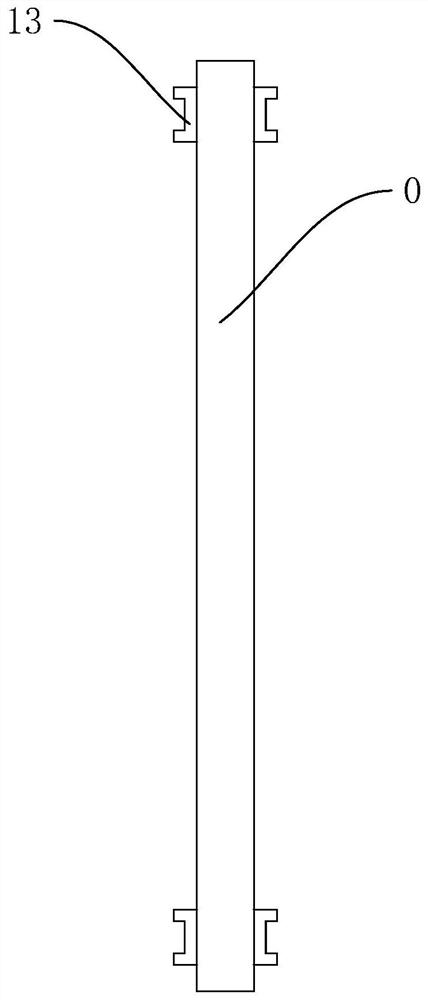

[0034] The embodiment of the present application discloses a shaft expansion forming device, referring to figure 2 and image 3 , including a body 1, the body 1 is a rectangular platform, the body 1 is provided with a clamping assembly 2, the clamping assembly 2 is used to clamp the pipe body 0, and the clamping assembly 2 is clamped at one end of the pipe body 0 close to the length direction, The tube body 0 clamps the clamping assembly 2 and one end is provided with a shaft expansion assembly 3, and the shaft expansion assembly 3 includes a mounting platform 31, and the mounting platform 31 and the tube body 0 end are installed on the body 1, and the mounting platform 31 faces close to or away from the tube body Sliding in the direction of 0, the side of the installation table 31 away from the 0 of the pipe body is equipped with a shaft expansion cylinder 32, and the piston rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com