Distribution network hot-line work robot system

A robot system and live work technology, applied in the directions of manipulators, program control manipulators, joints, etc., can solve the problems of small distance between lines, difficult to carry out live work, high labor intensity, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The technical solutions of the present invention will be further described in detail below by accoverts and examples.

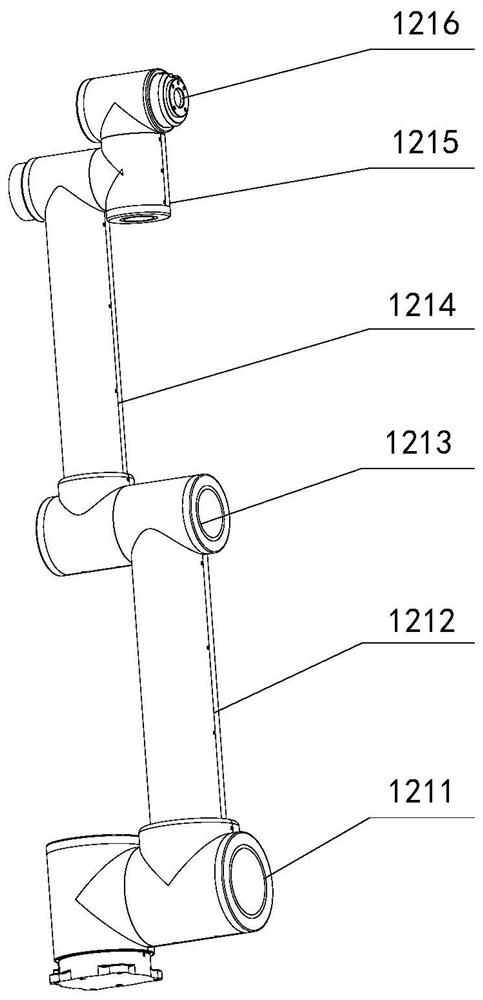

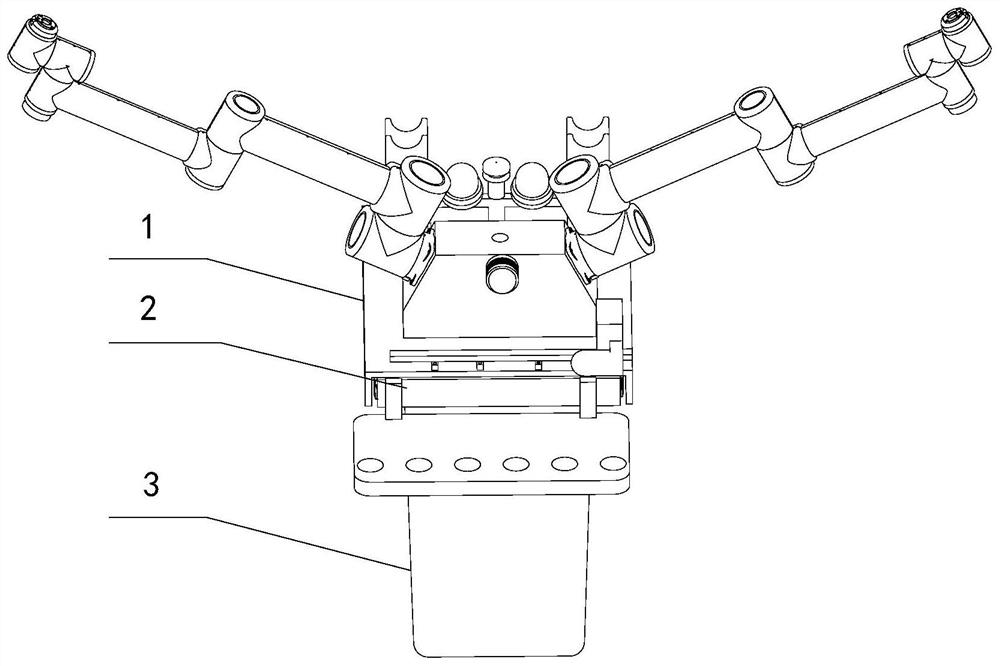

[0044] The distribution network of the present invention has the characteristics of miniaturization, lightweight, and the separation design of the workstable device and the support device, and the multi-joints of the robotic arms, which are freedom in a small job space. Sports, automatic fast replacement of the work tool, enhance the automatic operation capacity of the system.

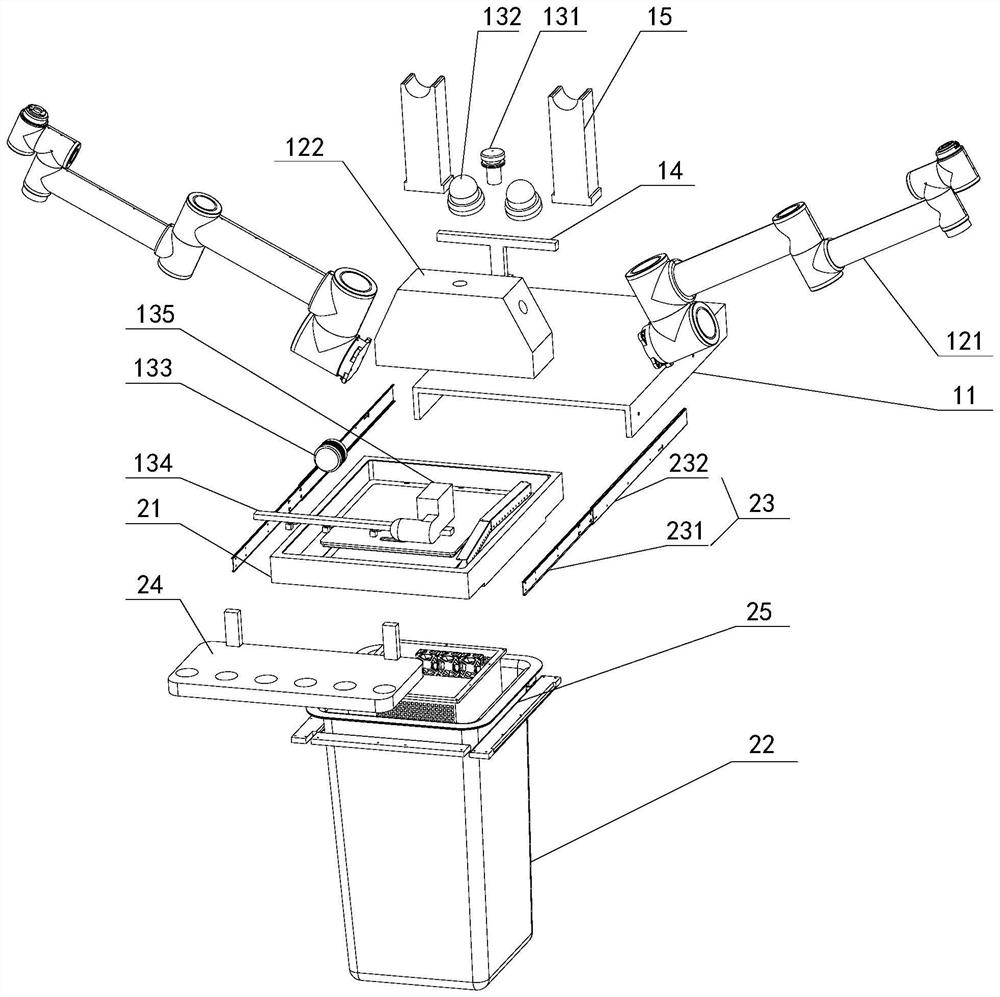

[0045] figure 1 An explosion diagram of the distribution network charging operation robot system provided by the embodiment of the present invention, image 3 The first structure of the distribution line charging operation robot system provided by the embodiment of the present invention, combined figure 1 with image 3 The present invention has been described in detail, and the distribution network-based operation robotic system includes: the operation table device 1, the support de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com