Cutting device with limiting structure for carton processing

A technology of limit structure and limit mechanism, which is used in packaging, papermaking, transportation and packaging, etc., can solve the problems of corrugated board deformation, corrugated board damage, and the impact of cutting accuracy, so as to avoid deformation and damage, prevent carton damage, The effect of keeping the air pressure stable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

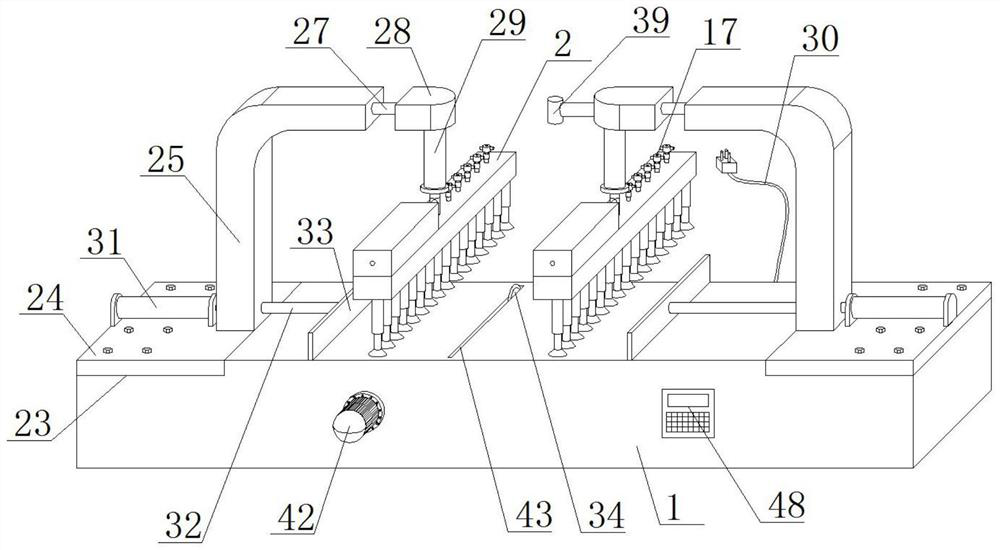

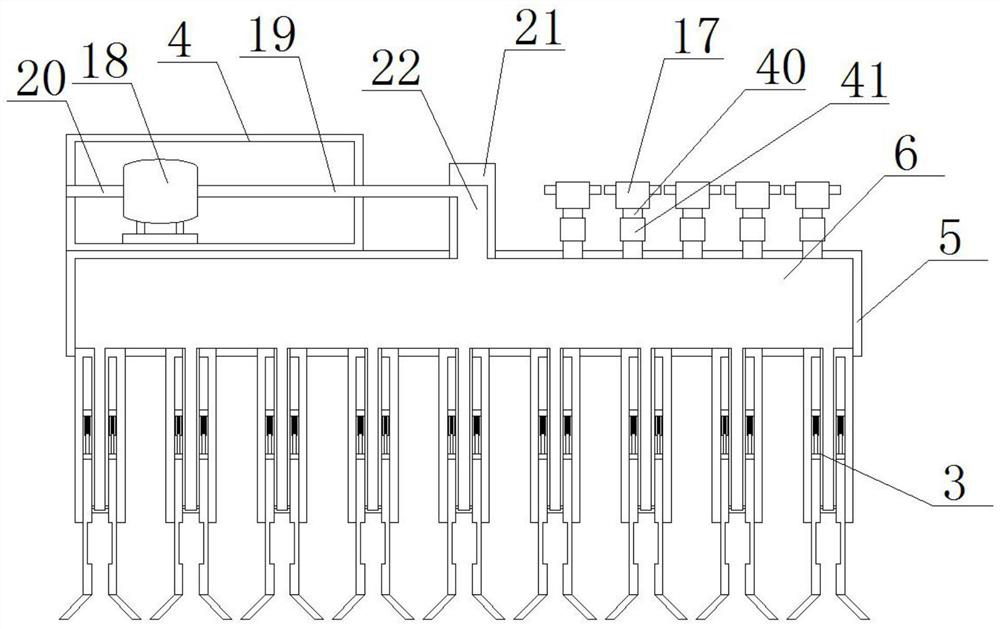

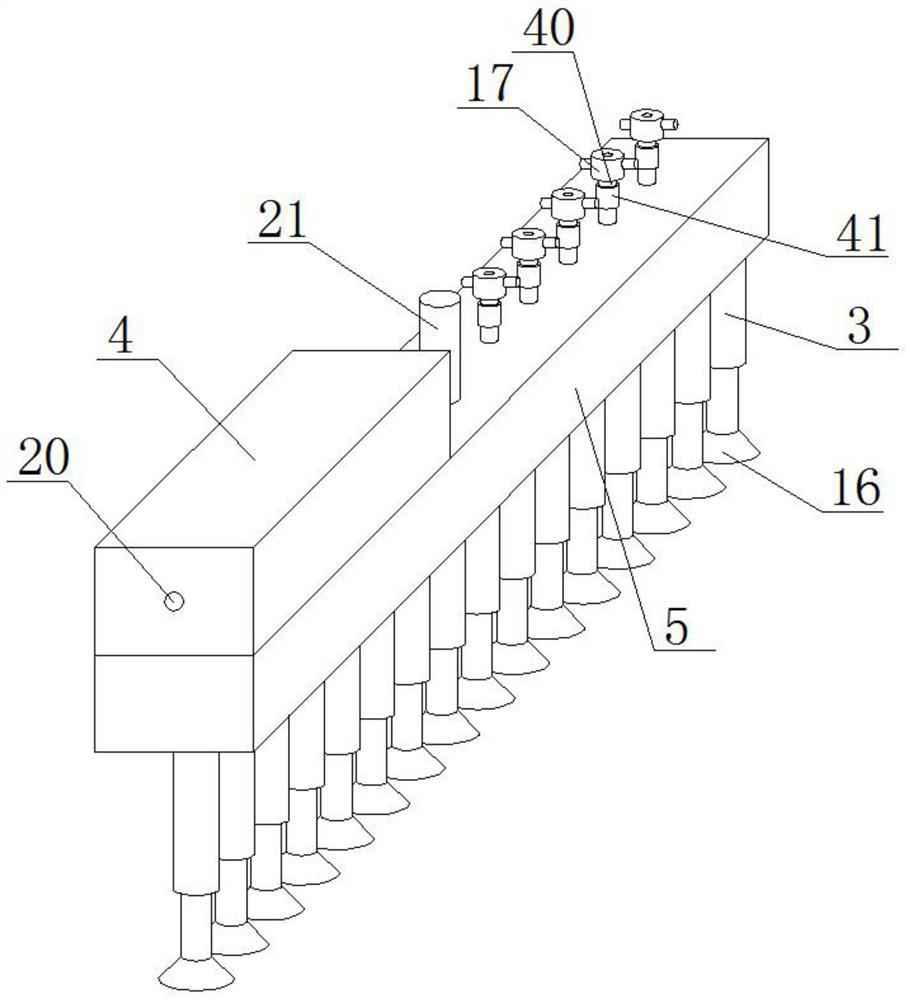

[0027] As a preferred embodiment of the present invention, a cutting mechanism 34 is fixedly installed in the workbench 1, and the cutting mechanism 34 includes a cutting seat 44, a cutting blade 46 and a ball screw 47, and the cutting seat 44 is fixedly installed There is a second motor 45, the cutting blade 46 is fixedly mounted on the output shaft of the second motor 45, the cutting seat 44 is provided with a through hole, and the cutting seat 44 is fixedly sleeved on the nut of the ball screw 47 through the through hole Above, the top of the workbench 1 is provided with a bar-shaped hole 43, the top of the cutting blade 46 is in the bar-shaped hole 43, the front side of the workbench 1 is equipped with a motor one 42, and the ball screw 47 It is fixedly connected with the output shaft of motor one 42, and a control panel 48 is installed on the front side of the workbench 1. The control panel 48 includes a processor and operation buttons, and the power cord 30 is respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com