Preparation method of non-woven fabric for X-ray and gamma-ray protection

A non-woven, gamma ray technology, applied in the field of radiation protection, can solve the problems of long time and many processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

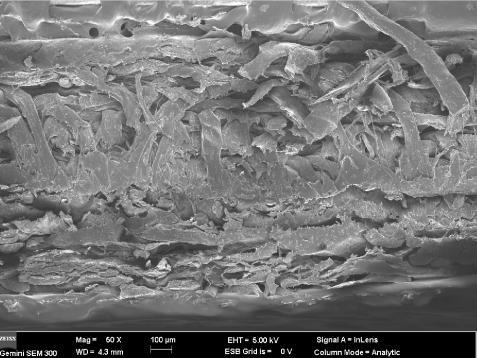

Image

Examples

Embodiment 1

[0054] This embodiment provides a method for preparing a non-woven fabric for protection against X and gamma rays, the method comprising the following steps:

[0055] (1) Prepare a dopamine salt solution with a concentration of 2g / L, add tris buffer to adjust the pH value of the solution to 8.5, then add tungsten powder cleaned with ethanol, stir with an electric stirrer for 24 hours, filter and separate, and then use deionized water respectively After washing twice with ethanol, dry at 80°C for 5 hours to obtain W@PDA;

[0056] (2) Add W@PDA obtained in step (1) to 0.3M / L gadolinium nitrate solution, stir magnetically for 2 hours, filter and separate, dry at 80°C for 5 hours, and then dry the prepared sample at 800°C Calcined at high temperature under nitrogen for 2h (heating rate 2°C / min), and finally obtained the core-shell structure W@Gd 2 o 3 powder.

[0057] (3) The core-shell structure W@Gd obtained in step (2) 2 o 3 The powder and the dried PP masterbatch are adde...

Embodiment 2

[0066] This embodiment provides a method for preparing a non-woven fabric for protection against X and gamma rays, the method comprising the following steps:

[0067] (1) Prepare a dopamine salt solution with a concentration of 1.5g / L, add tris buffer to adjust the pH value of the solution to 8, then add tungsten powder cleaned with ethanol, stir with an electric stirrer for 20 hours, filter and separate, and then use deionized After washing with water and ethanol for 3 times, it was dried at 60°C for 8 hours to obtain W@PDA;

[0068] (2) Add the W@PDA obtained in step (1) into a 0.35M / L gadolinium nitrate solution, stir magnetically for 3 hours, filter and separate, dry at 60°C for 8 hours, and then dry the prepared sample at 900°C Calcined at high temperature under nitrogen for 2.5h (heating rate 3°C / min), and finally obtained the core-shell structure W@Gd 2 o 3 powder.

[0069] (3) The core-shell structure W@Gd obtained in step (2) 2 o 3 The powder and the dried PP mas...

Embodiment 3

[0077] This embodiment provides a method for preparing a non-woven fabric for protection against X and gamma rays, the method comprising the following steps:

[0078](1) Prepare a dopamine salt solution with a concentration of 2.5g / L, add tris buffer to adjust the pH value of the solution to 9, then add tungsten powder cleaned with ethanol, stir with an electric stirrer for 18 hours, filter and separate, and then use deionized After washing twice with water and ethanol, dry at 70°C for 6 hours to obtain W@PDA;

[0079] (2) Add W@PDA obtained in step (1) to 0.4M / L gadolinium nitrate solution, stir magnetically for 2.5h, filter and separate, dry at 70°C for 6h, and then place the prepared sample in Calcined at 1000°C for 3h under nitrogen gas (heating rate 4°C / min), and finally got the core-shell structure W@Gd 2 o 3 powder.

[0080] (3) The core-shell structure W@Gd obtained in step (2) 2 o 3 The powder and the dried PP masterbatch are added to the feeding port of the scre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com