Fabricated building main body protection device

A technology of building main body and protective device, which is applied in the direction of construction, building structure, and building material processing. It can solve the problems of inability to adjust the protective effect of supports and the fixed structure of protective devices, so as to improve the protective effect, facilitate docking installation, and ensure The effect of support and protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

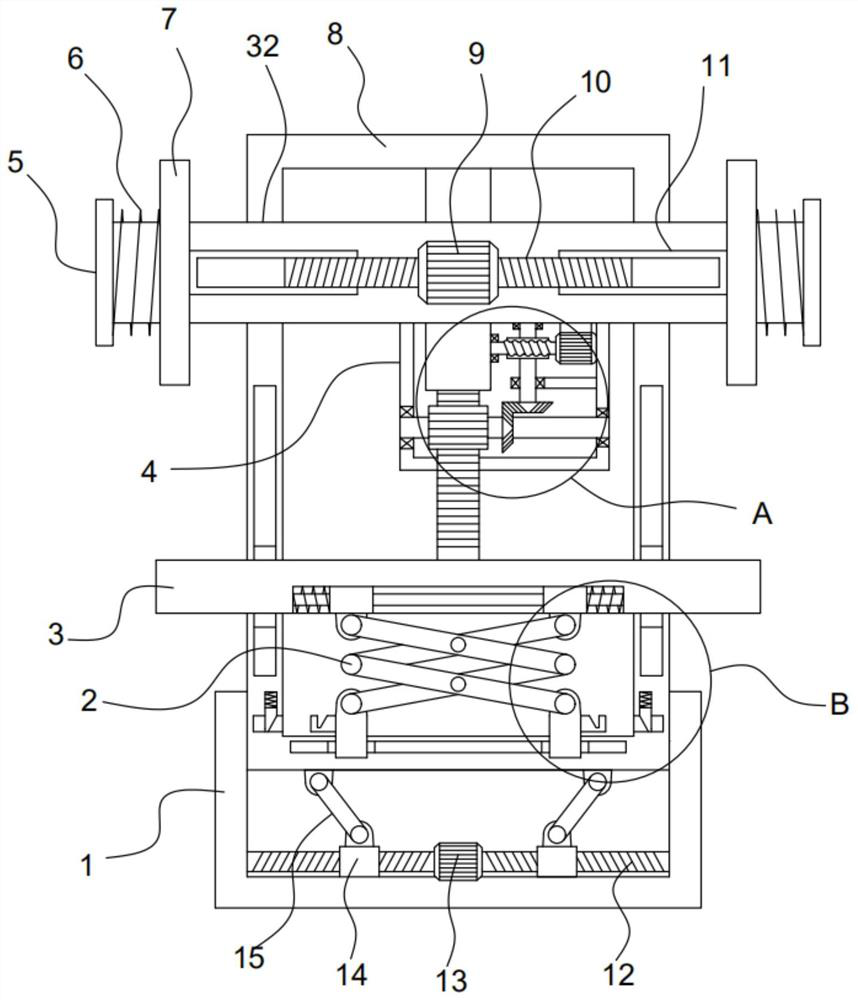

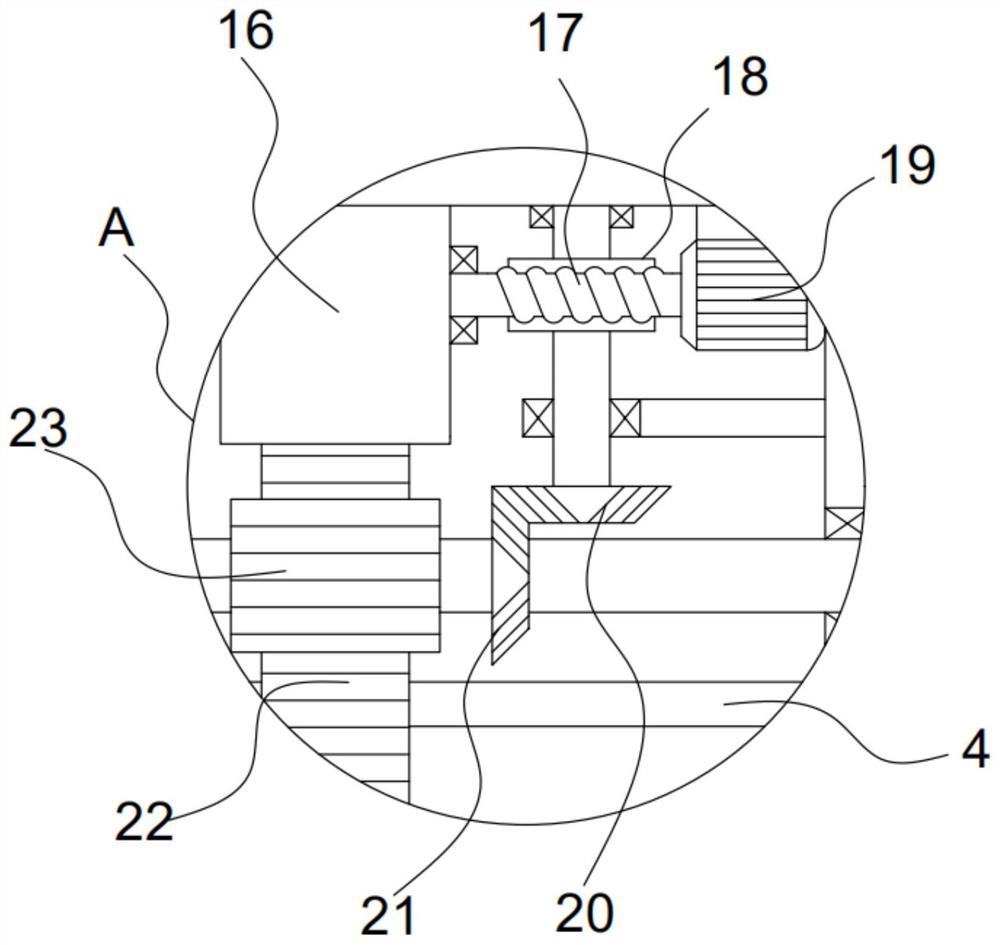

[0023] see Figure 1-4 , a prefabricated building body protection device, comprising a support base 1, a protective frame 8 is slidably installed on the support base 1, and a height adjustment mechanism for driving the vertical lifting of the protective frame 8 is provided on the support base 1, and the protective frame 8 A horizontally arranged bottom pallet 3 is slidingly installed on the upper side, and a guide column 32 is fixed horizontally on the protective frame 8, and a lateral limit mechanism for clamping the assembly is provided on the guide column 32. A transmission frame 4 is provided, and the transmission frame 4 is provided with a lifting adjustment mechanism for driving the bottom pallet 3 to slide relative to the protective frame 8 , and an anti-fall protection mechanism is provided between the bottom pallet 3 and the protective frame 8 .

[0024] The height adjustment mechanism of the device includes two output shafts of the biaxial motor II13 fixed on the sup...

Embodiment 2

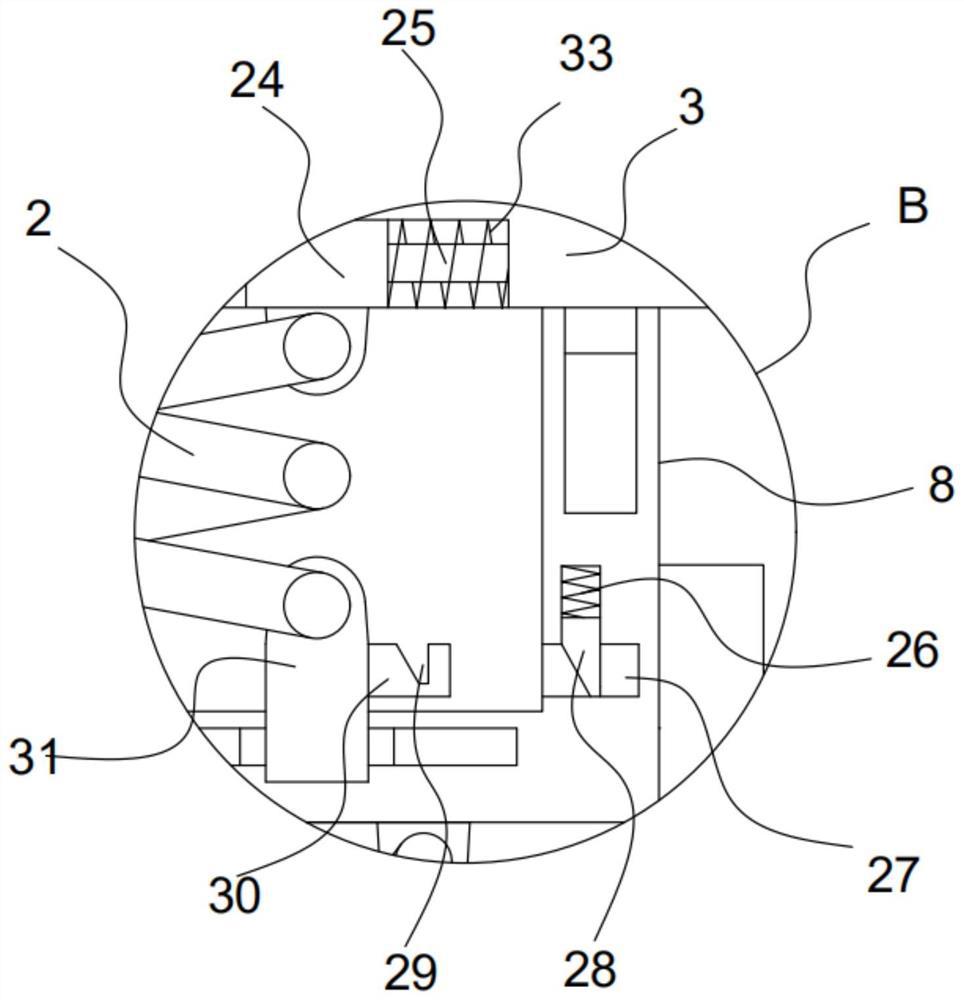

[0031] On the basis of Embodiment 1, in addition, the device is also provided with an anti-fall protection mechanism, including a telescopic frame 2 arranged between the bottom support plate 3 and the protective frame 8, the upper end of the telescopic frame 2 is hinged with a sliding sleeve 24, and the sliding sleeve 24 is horizontally pierced with a guide rod 25 fixed on the bottom pallet 3, and the lower end of the telescopic frame 2 is hinged with a sliding frame 31 slidably installed on the protective frame 8. Between the sliding sleeve 24 and the bottom pallet 3 A buffer spring 33 is fixed.

[0032] Through the above settings, in the process of installing the assembly, when the assembly accidentally falls, the bottom bracket 3 is provided to support and protect it, the bottom bracket 3 is impacted and moves down, and the telescopic frame 2 is deformed. At this time, the elastic deformation of the buffer spring 33 is used for buffering and shock absorption, which has a go...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com