Device and method for determining resistance value of printing head and printer

A technology for determining devices and print heads, applied in printing devices, printing, etc., can solve problems such as the accuracy of thermal resistance resistance of the print head and low work efficiency, achieve improved accuracy and work efficiency, simple structure, and improved user experience degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

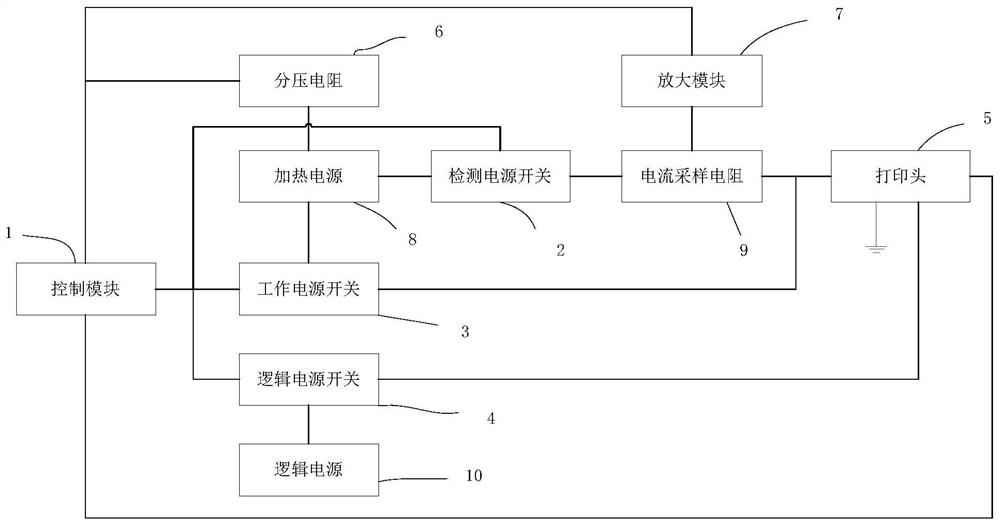

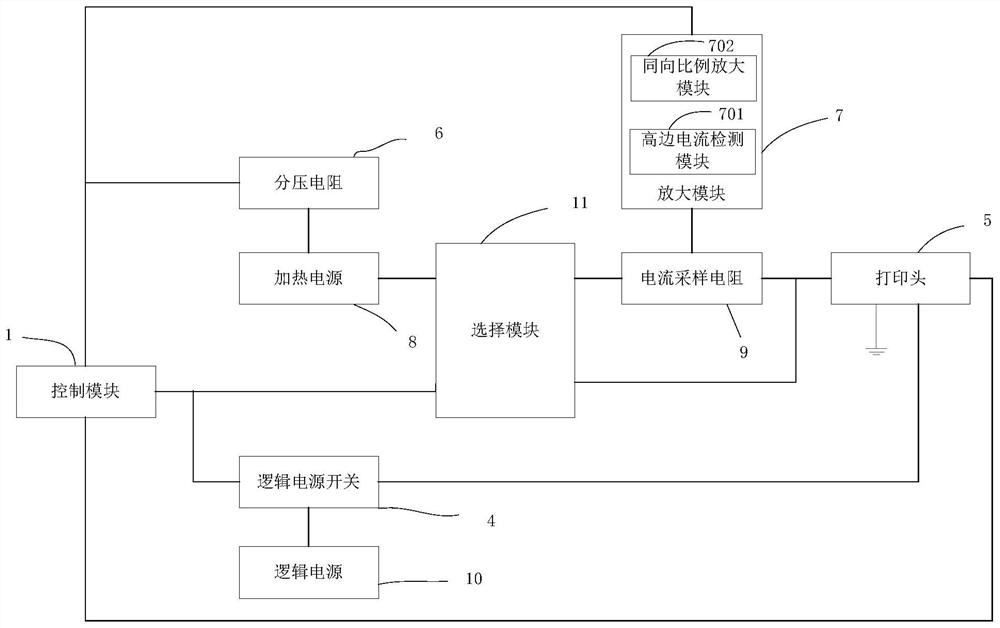

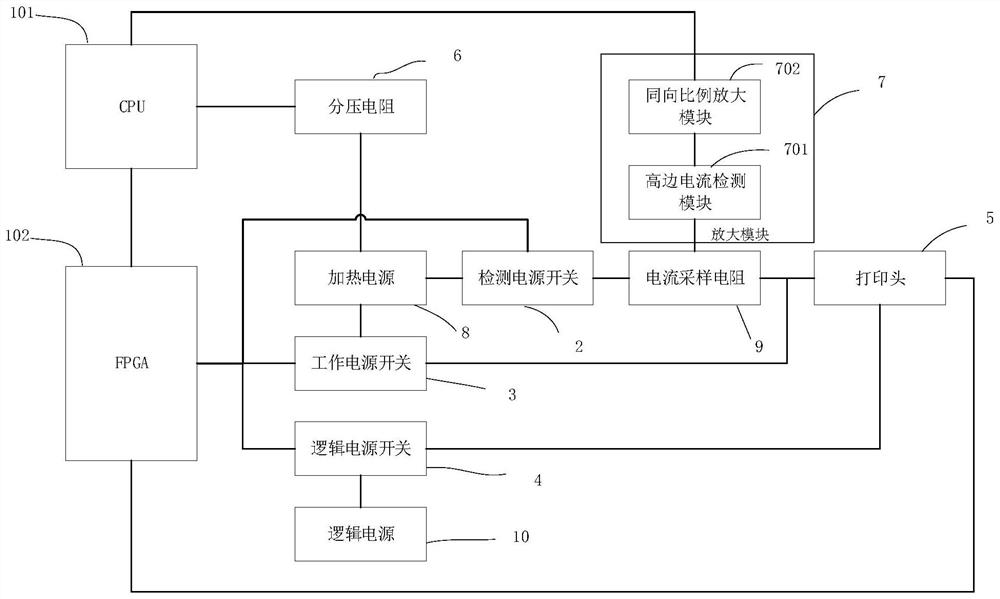

[0051] see figure 1 , an embodiment of the present invention provides a print head resistance detection device, including:

[0052] The control module 1 is respectively connected to the detection power switch 2, the working power switch 3, the printing head 5, and the voltage dividing resistor 6, and is used to respectively control the working states of the printing head 5, the detection power switch 2, and the working power switch 3;

[0053] The heating power supply 8 is respectively connected to the detection power switch 2, the working power switch 3 and the voltage dividing resistor 6;

[0054] The current sampling resistor 9 is connected to the detection power switch 2 respectively;

[0055] The print head 5 is also connected to the current sampling resistor 9 and the working power switch 3 respectively.

[0056] Optionally, the voltage dividing resistor is used to divide the heating power supply.

[0057] Optionally, the print head is grounded.

[0058] In some embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com