Material conveying device based on electric automatization

A technology of electrical automation and transportation devices, which is applied in the direction of transportation and packaging, packaging, containers, etc., can solve the problems of low efficiency, cumbersome and inconvenient adjustment operations, etc., and achieve the effects of high efficiency, convenient and quick adjustment operations, and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

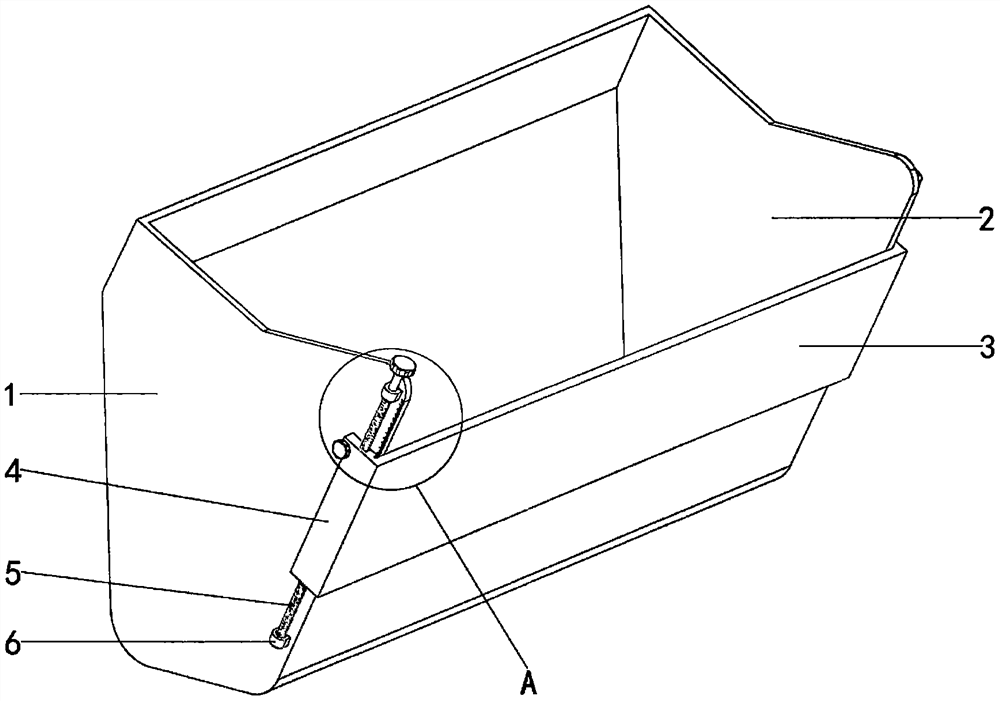

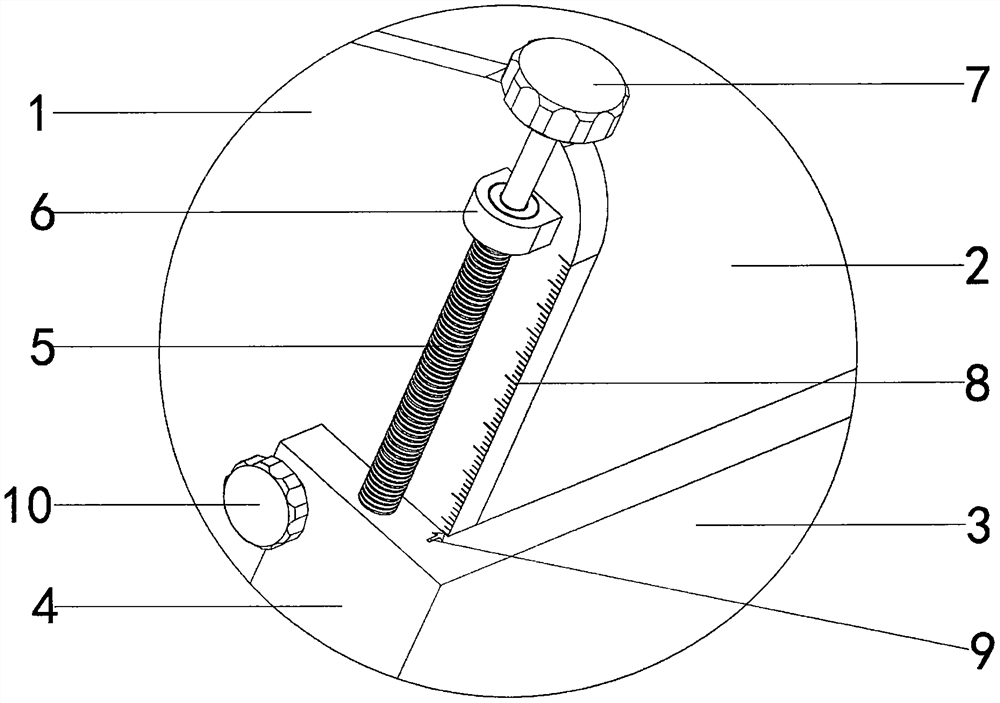

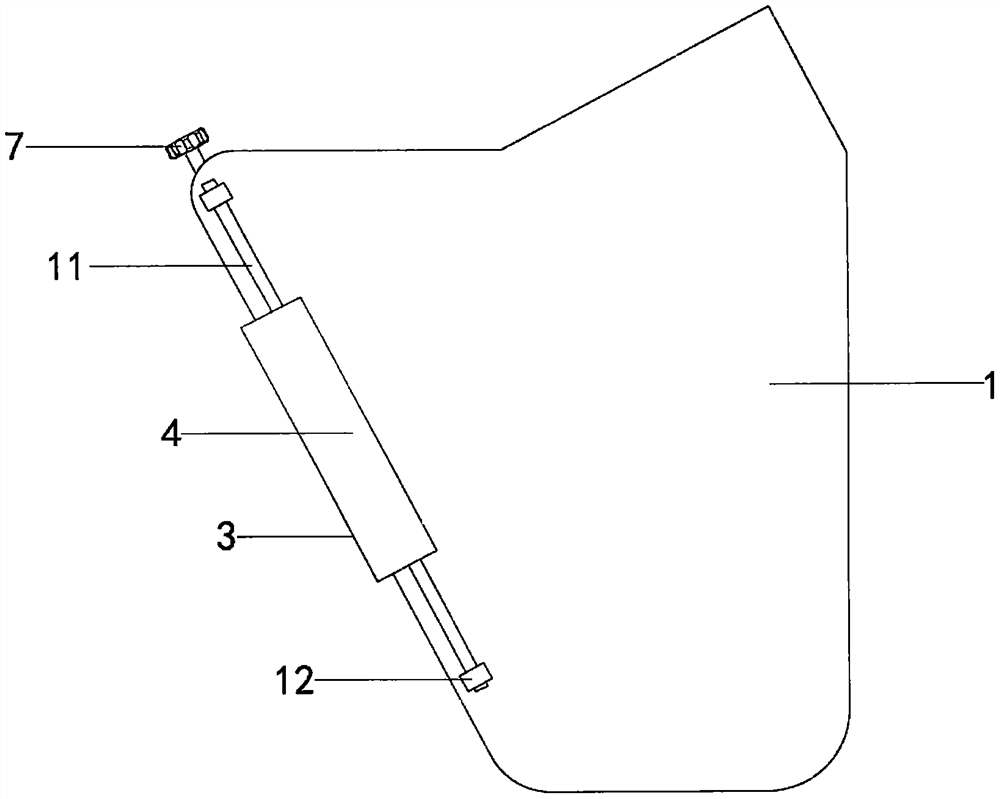

[0025] A material conveying device based on electrical automation, including: bucket body 1, overflow port 2, material blocking plate 3, slider 4, threaded rod 5, swivel seat 6, knob 7, scale 8, pointer 9, hand screw 10. Polished rod 11, fixed seat 12; the top of the front end of the bucket body 1 is provided with a rectangular overflow port 2, and the front end of the overflow port 2 is provided with a rectangular material blocking plate 3; the left and right ends of the material blocking plate 3 A rectangular plate-shaped slider 4 is welded, and the slider 4 is slidingly connected to the side end of the bucket body 1; the middle position of the left slider 4 is vertically penetrated with a threaded rod 5, and the threaded rod 5 is threaded with the slider 4 The upper and lower ends of the threaded rod 5 are rotatably connected with a rectangular block-shaped swivel seat 6, and the swivel seat 6 bolts are fixed on the left end of the bucket body 1; the top of the threaded rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com