Novel automatic bottle unloading device for canned bottles

A new type of technology for cans and bottles, which is applied in the direction of unstacking, transportation and packaging of objects, conveyor objects, etc. It can solve the problems of high cost, inconvenient adjustment of side limit plates, and low efficiency of manual removal of empty pallets.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

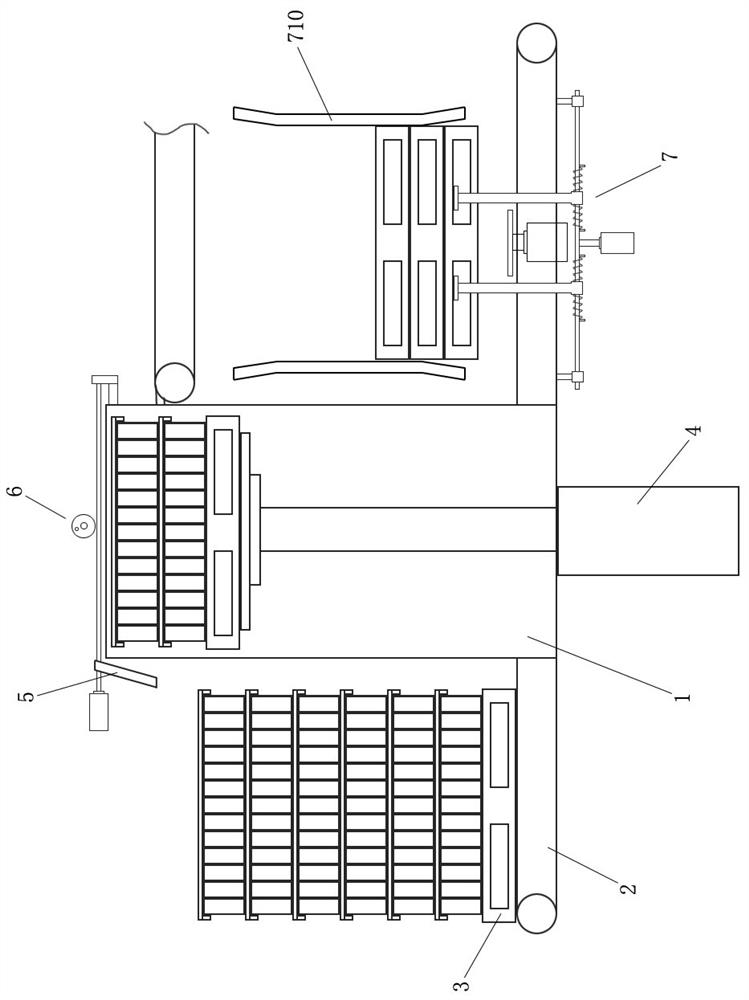

[0033] refer to Figure 1 to Figure 6 , the present invention is a novel automatic bottle unloading device for canned bottles, which includes a destacking bin 1 with a lifting cylinder 4 at the bottom; the bottom of the destacking bin 1 is provided with a horizontal conveyor belt 2 driven by a conveying motor; The top of the destacking bin 1 is provided with a pusher plate 5 that moves horizontally through a driving component;

[0034] The top and one side of the destacking bin 1 are respectively provided with a support limit mechanism 6 and a pallet stacking mechanism 7;

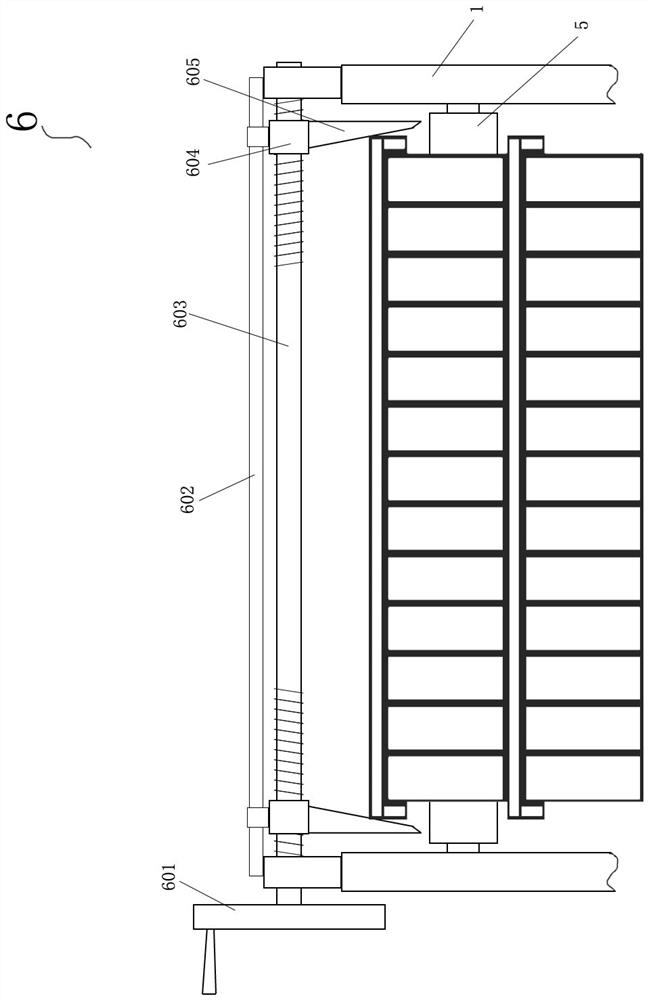

[0035] The supporting position-limiting mechanism 6 includes a two-way screw rod 603 spanning the width direction of the top of the destacking bin 1; two ends of the two-way screw rod 603 are respectively provided with sliding sleeves 604 which are threaded and move relative to each other in opposite directions. , and the bottom ends of the sliding sleeves 604 are respectively fixed with side aligning plat...

Embodiment 2

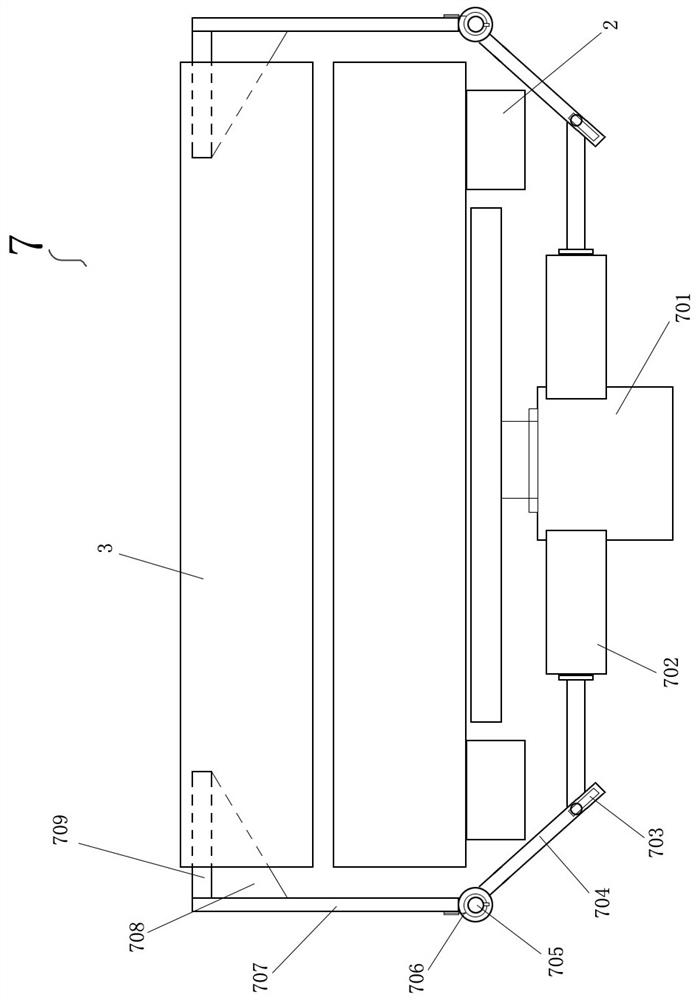

[0039] refer to figure 1 The pallet stacking mechanism 7 also includes a side regularizing plate 710 arranged along the traveling direction of the horizontal conveyor belt; the side regularizing plate 710 is symmetrically arranged on the front and rear sides of the stacking cylinder 701, and is connected to Device frame connection. The bottom ends of the side regularizing plates 710 respectively have a reverse outward expansion structure. This structure can play the role of regular alignment in the front and rear directions, and the expanded structure at the bottom facilitates the smooth insertion and return of skewed pallets.

[0040] refer to Figure 3 to Figure 6The lifting plate 709 is separated from the horizontal conveyor belt 2 by at least one pallet 3 height distance. This height distance is to facilitate the entry of subsequent empty pallets and realize lifting and stacking from bottom to top.

[0041] refer to figure 2 , the inner opposite surfaces of the side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com