Water-saving printing and dyeing equipment

A kind of printing and dyeing equipment and water-saving technology, which is applied to the configuration of textile material processing equipment, spray/jet textile material treatment, climate sustainability, etc., and can solve the problems of dye liquor that cannot be directly reused, dye liquor waste, dripping, etc. , to achieve the effect of reducing uneven dyeing, saving water resources and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The following is attached Figure 1-8 The application is described in further detail.

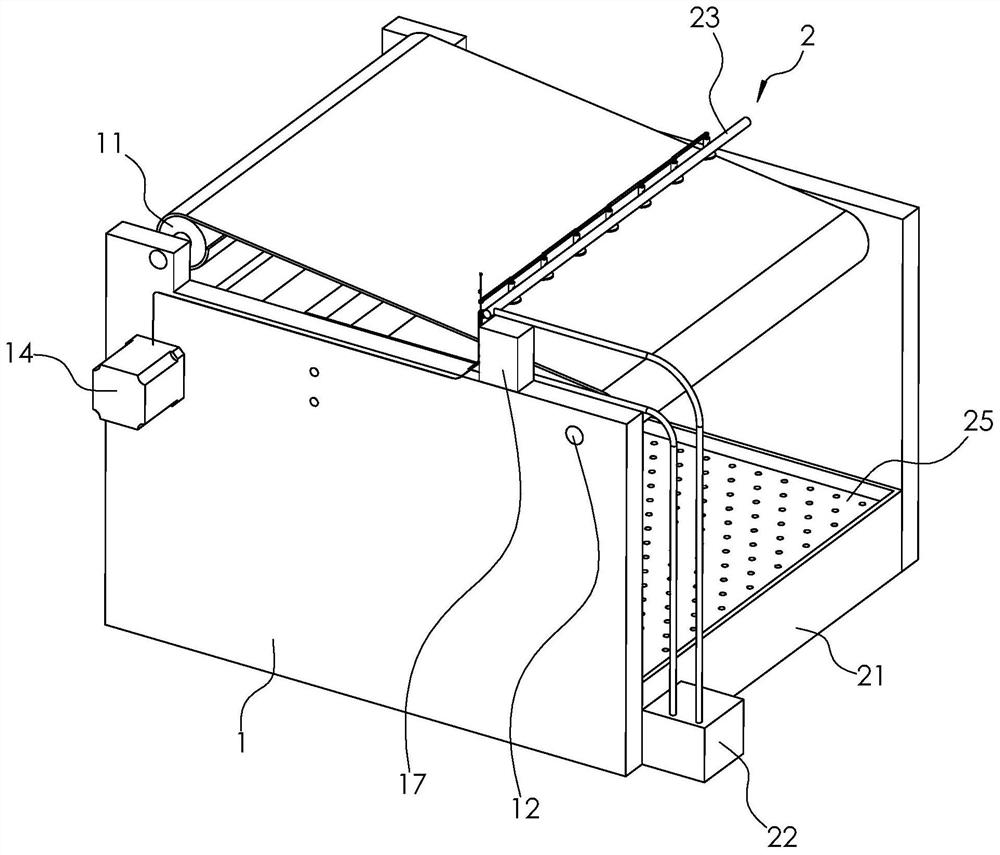

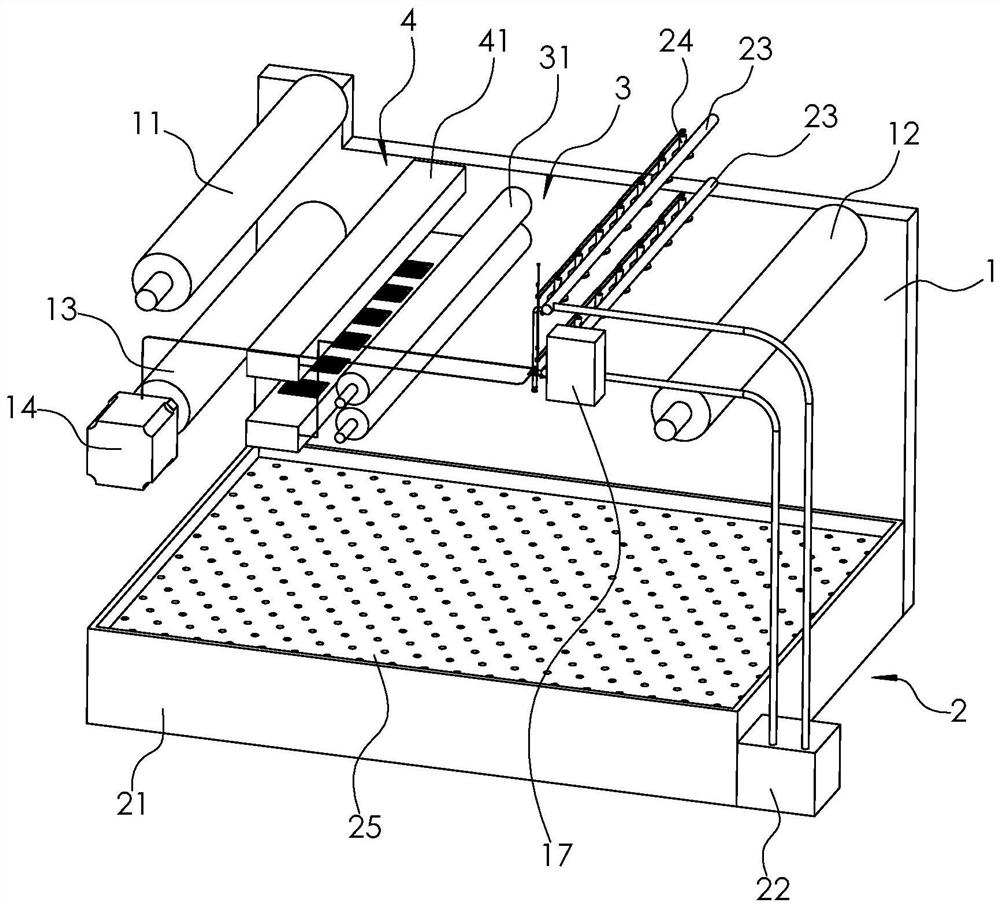

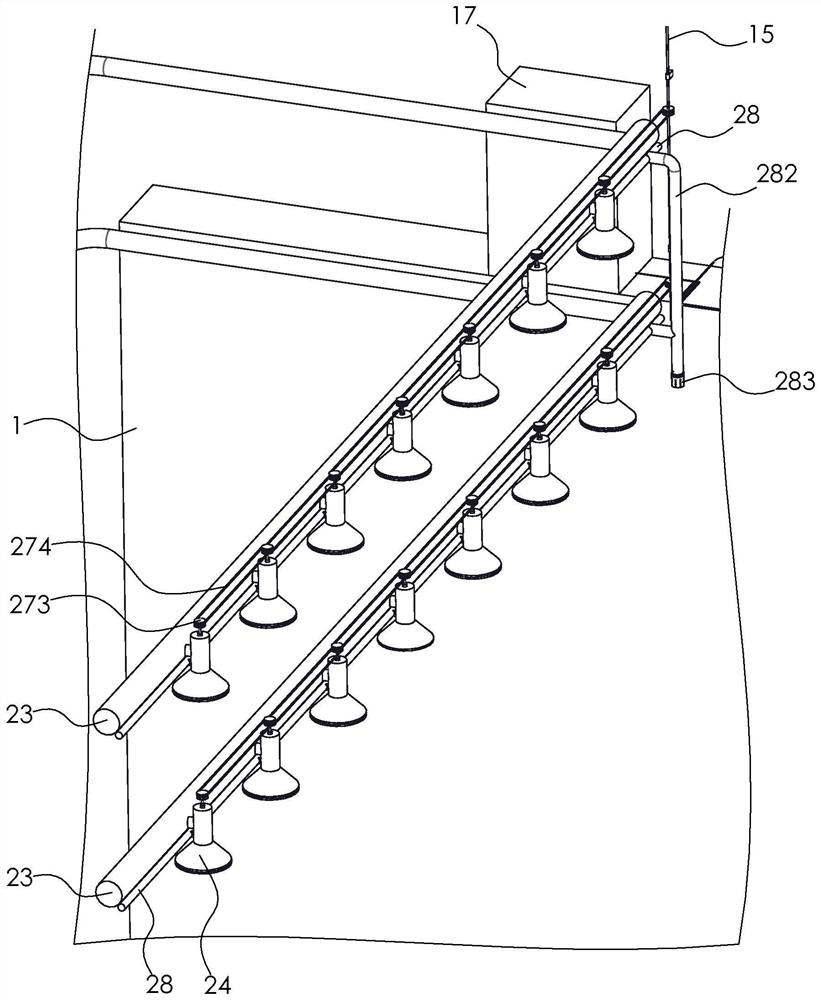

[0045] The embodiment of the present application discloses a water-saving printing and dyeing equipment. Such as figure 1 with figure 2 As shown, a water-saving printing and dyeing equipment includes a support 1 , a liquid spraying device 2 , a water squeezing device 3 and a drying device 4 . The support 1 is rotatably connected with a feed roller 11, a guide roller 12 and a winding roller 13 arranged horizontally. A motor 14 is also fixed on the side of the roller 13 ; During the printing and dyeing process of the fabric, the fabric will bypass the feed roller 11, the guide roller 12 and the take-up roller 13 in turn, the motor 14 will drive the take-up roller 13 to rotate and wind the fabric, and the liquid spray device 2 sprays the dye solution to the fabric, The water squeezing device 3 squeezes out excess dye liquor on the printed and dyed fabric, and the drying device 4 d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com