Device and method for detecting bearing capacity of honeycomb steel arch in plane

A detection device and bearing capacity technology, applied in the measurement device, using stable tension/pressure to test material strength, height/level measurement, etc. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

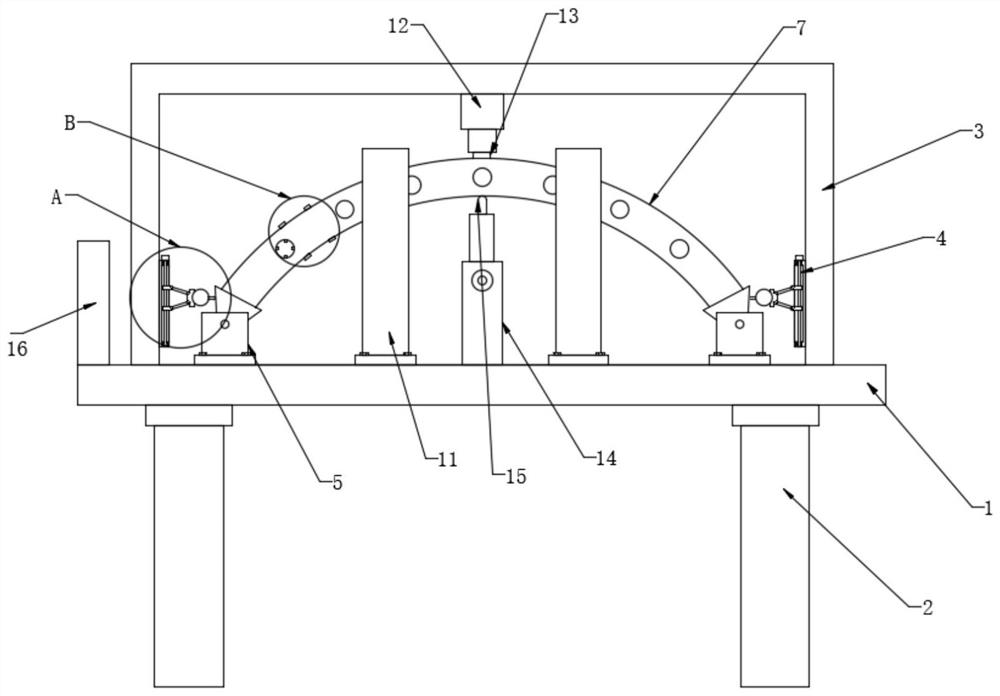

[0028] Embodiment 1 A detection device for the bearing capacity of a honeycomb steel arch in a plane according to the present invention includes a workbench for supporting, a pair of fixing units for fixing the honeycomb steel arch 7, and applying Vertical loading unit and detection unit for vertical load,

[0029] The workbench includes a table top 1, a gantry frame 3 and several legs 2, the table top 1 is horizontally arranged on the legs 2; A pair of said fixed units are installed symmetrically between the two vertical columns;

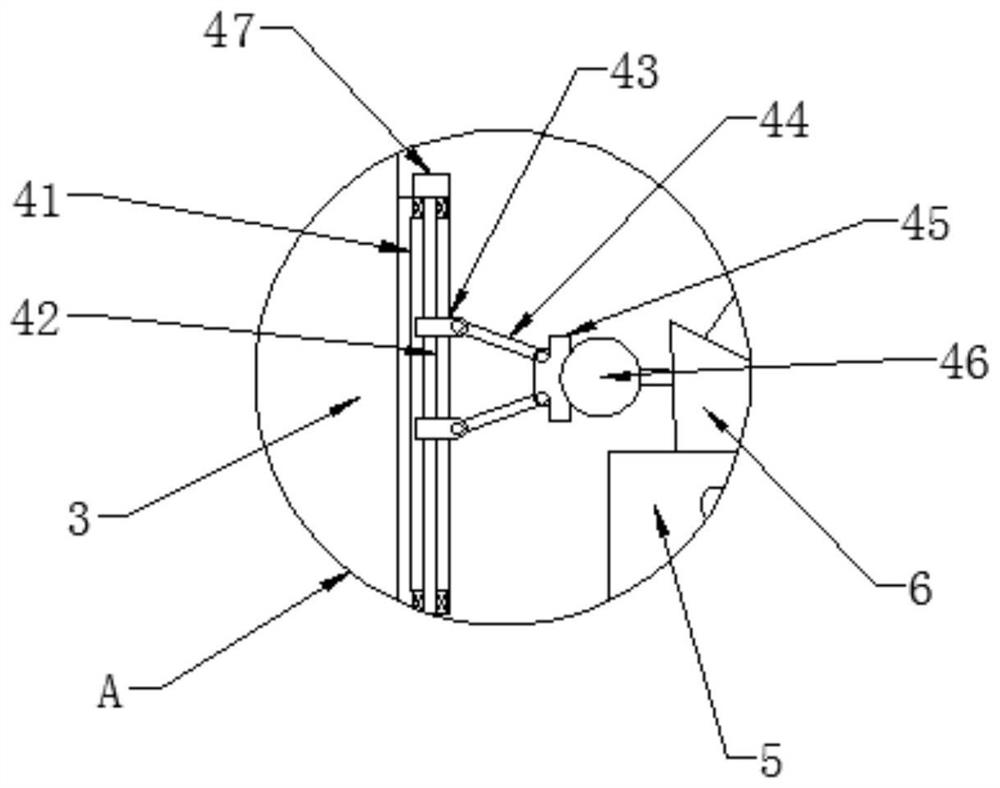

[0030] The fixing unit includes a fixing seat 5 and a mounting frame 6, the bottom of the fixing seat 5 is fixedly connected with the table top 1, the mounting frame 6 is rotatably connected in the fixing seat 5, and a mounting frame 6 is installed between the mounting frames 6. Honeycomb steel arch 7;

[0031] The vertical loading unit includes a jack 12 and a pressure sensor 13, the jack 12 is vertically suspended on the beam of the gantry 3, a...

Embodiment 2

[0038] Embodiment 2 adopts the detection method of the detection device for the in-plane honeycomb steel arch bearing capacity as described in the present invention, comprising the following steps:

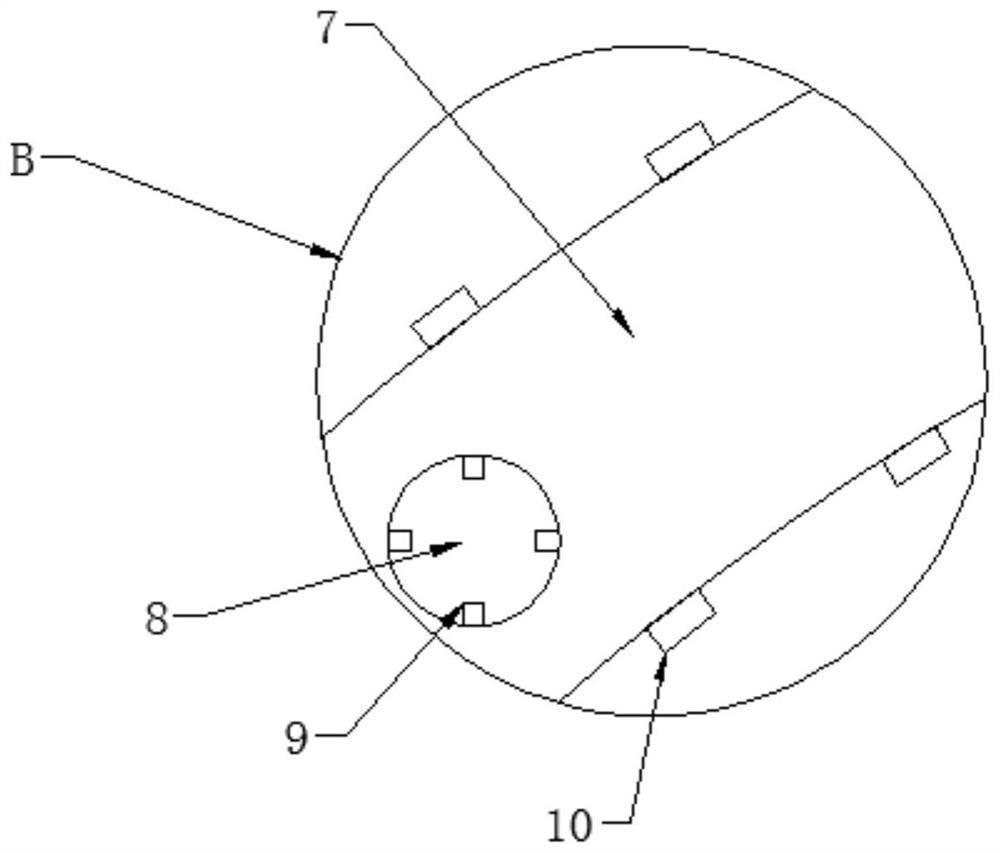

[0039] S1: Adjust the distance between the two fixing seats 5 and the angle of the installation frame 6 according to the specifications of the honeycomb steel arch 7, install the honeycomb steel arch 7 on the installation frame 6, and fix the limiting plate 11 on the honeycomb steel arch by bolts 7 on both sides to limit the out-of-plane displacement of the honeycomb steel arch 7, then the first strain gauge 9 is installed in the honeycomb hole 8 of the honeycomb steel arch 7, and the second strain gauge 10 is installed on the inner and outer surfaces of the honeycomb steel arch 7 , then pull the movable rod 142, the movable rod 142 drives the displacement sensor 15 upwards so that the detection axis of the displacement sensor 15 contacts the bottom of the mid-span position of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com