Impurity filtering device for dairy product processing

A technology for impurity filtration and dairy products, which is applied in food processing, filtration separation, and filtration circuits. It can solve the problems of difficult disassembly, replacement and cleaning, poor filtration effect, time-consuming and labor-intensive problems, so as to improve the filtration effect and avoid the blockage of the filter screen. , Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

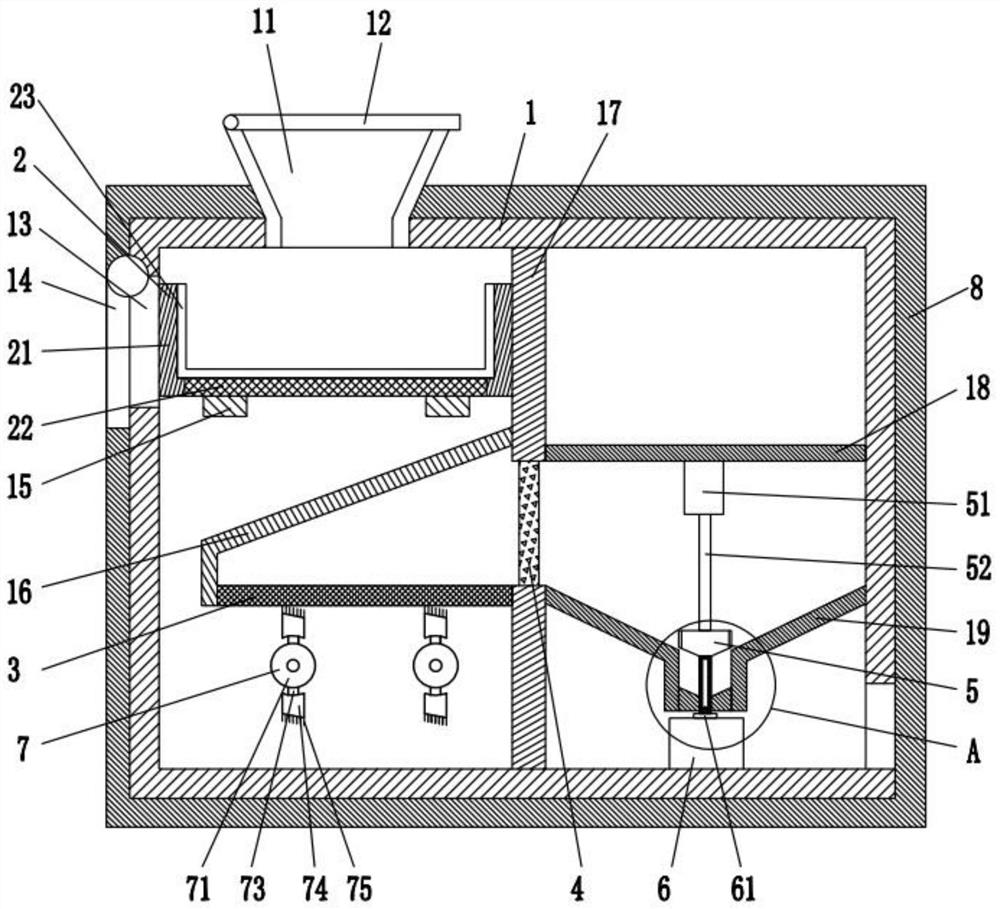

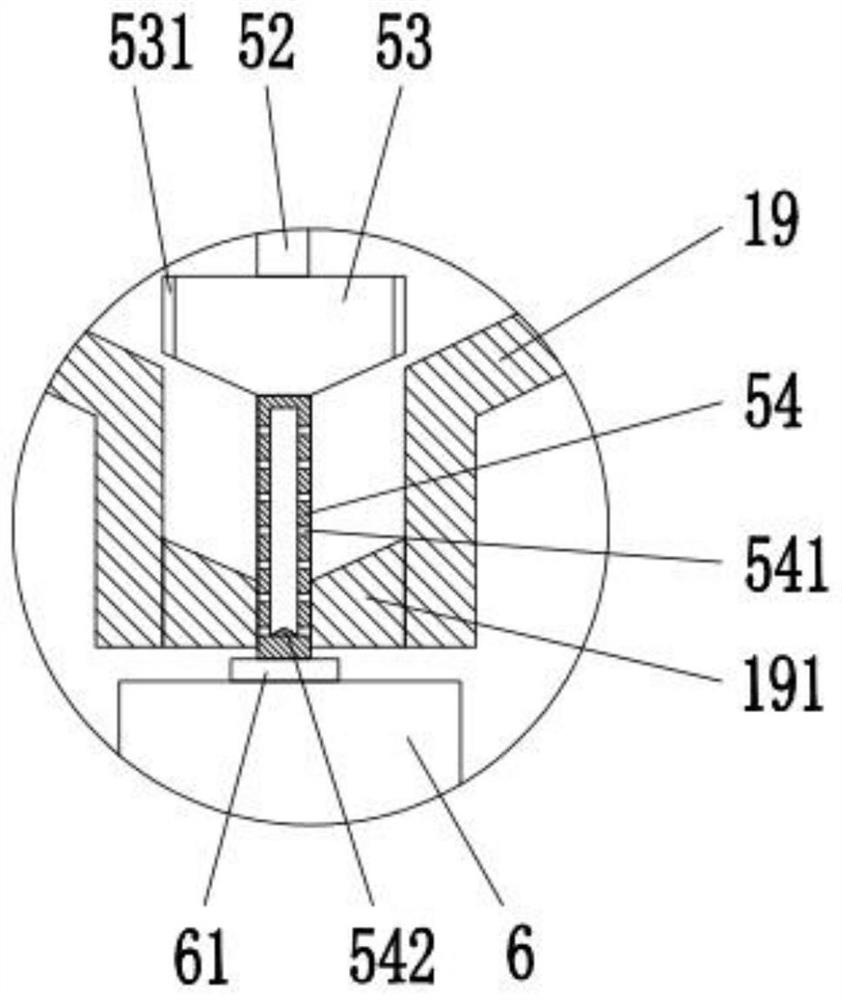

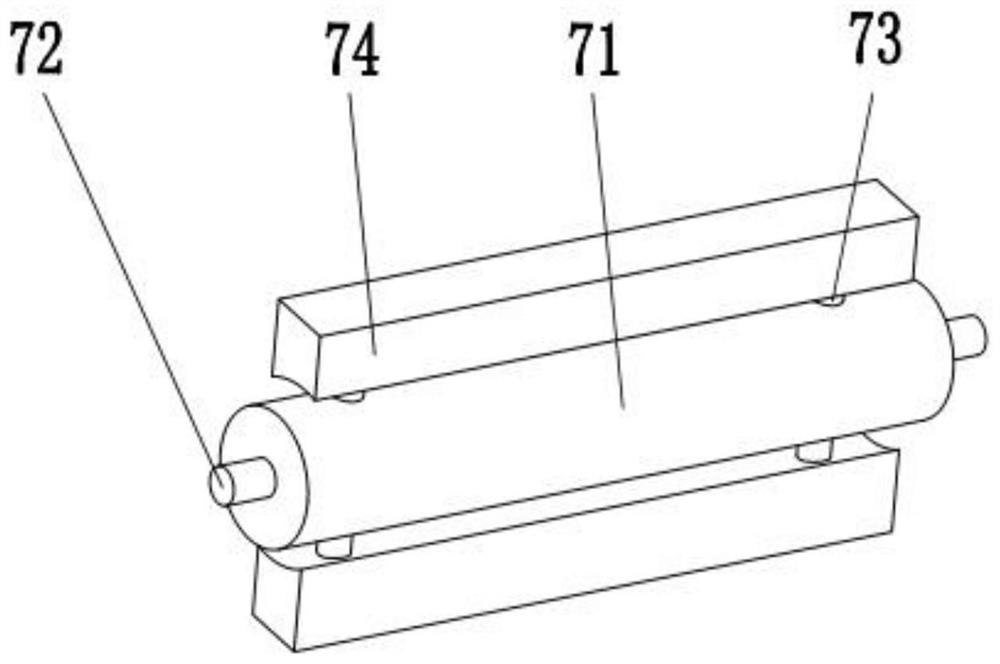

[0019] Such as Figure 1 to 3 As shown, an impurity filtering device for dairy product, including the outer casing 1, the filter box 2, the second filter 3, the adsorbing plate 4, the discharge assembly 5, and the storage box 6, and the outer casing 1 is provided Insulation layer 8, the outer casing 1 is provided with a vertical block 17 and the vertical separator 17 separates the outer casing 1 to the left chamber and the right chamber, and the top of the left chamber is provided. The bucket 11, the upper portion is mounted, and there are several placing plates 15 in the upper portion, and there is a guide flap 16 in which the guide flap 16 is fixed. The top end of the hopper 11 is provided with a forming cover 12, and both ends of the placement plate 15. The filter box 2 includes a casing 21 and a first filter 22, respectively, and the casing 21 is placed on the placement plate 15, and the first filter 22 is disposed. On the bottom wall of the casing 21, an ultrasonic assembly 23...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com