Low-Pt long-chain alkane dehydrogenation catalyst as well as preparation method and application thereof

A technology for dehydrogenation catalysts and long-chain alkanes, which is applied in the field of catalysis and can solve problems such as inapplicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

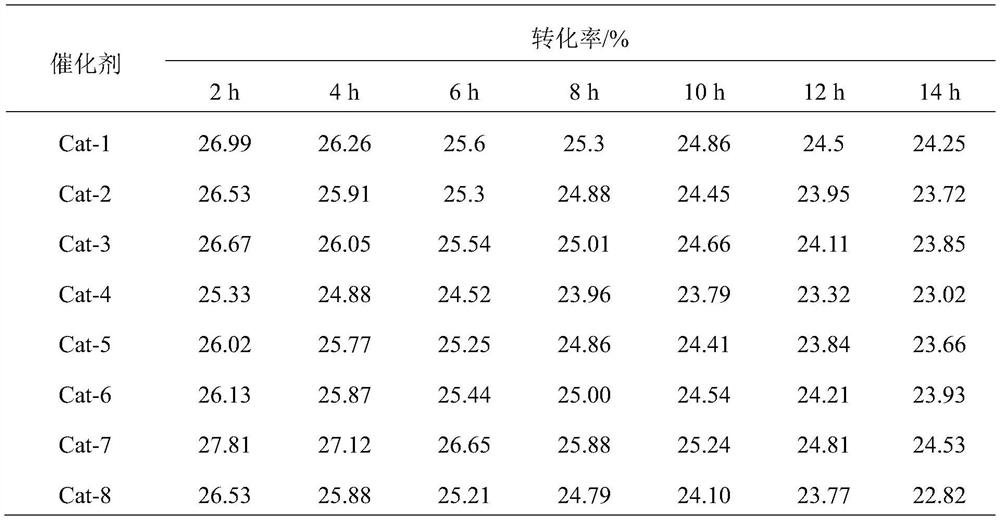

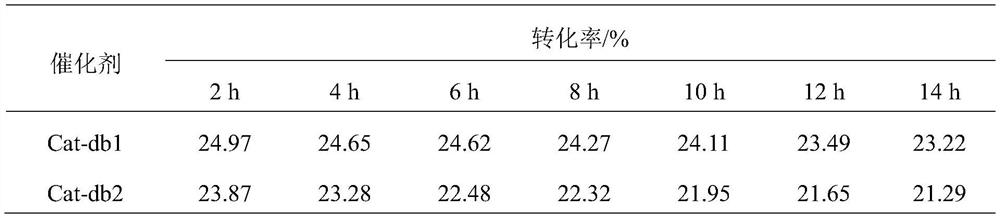

Examples

preparation example Construction

[0030] According to a typical embodiment of the present invention, a method for preparing the above-mentioned low-Pt long-chain alkane dehydrogenation catalyst is provided. The preparation method comprises the following steps: S1, immersing the carrier in an aqueous solution containing soluble salts of Pt, Ni, Fe and alkali metals, then drying and roasting to obtain a primary catalyst; S2, washing the primary catalyst with water to obtain a secondary catalyst and S3, reducing the secondary catalyst in hydrogen to obtain a low-Pt long-chain alkane dehydrogenation catalyst.

[0031] Preferably, in S1, impregnating the carrier in an aqueous solution containing soluble salts of Pt, Ni, Fe and alkali metals is: impregnating the carrier in an aqueous solution containing soluble salts of Pt, Ni, Fe and alkali metals respectively, or containing two Or in a mixed solution of soluble salts corresponding to two or more metals; more preferably, the roasting temperature in S1 is 300-600°C....

Embodiment 1

[0037] Catalyst Preparation 1

[0038] The carrier of the catalyst is spherical γ-Al prepared according to Chinese patent CN104907103A 2 o 3 , whose technical specifications are:

[0039] Specific surface area: 205m 2 / g

[0040] Total pore volume: 1.71mL / g

[0041] Bulk density: 0.28g / mL

[0042] Water absorption: 2.0mL / g

[0043] Particle size: 1.5~2.5mm

[0044] 10g of this γ-Al 2 o 3 Vacuum equal volume immersion in 20mL mixed solution containing 0.08g chloroplatinic acid, 0.43g nickel chloride and 0.29g ferric chloride, after drying, bake at 500°C for 2 hours. After cooling, further impregnate in 20mL aqueous solution containing 0.14g potassium chloride in vacuum equal volume, after drying, roast at 500°C for 2 hours, and then wash with water at 500°C in a water vapor-air mixture with a water vapor content of 10%. 8h. After reduction at 400°C for 2 hours under a hydrogen atmosphere, a long-chain alkane dehydrogenation catalyst with a component content of 0.3% P...

Embodiment 2

[0046] Catalyst Preparation 2

[0047] The γ-Al described in 10g embodiment 1 2 o 3 Immerse in 20 mL of a mixed solution containing 0.14 g of potassium chloride, 0.43 g of nickel chloride and 0.29 g of ferric chloride in 20 mL of vacuum equal volume, after drying, bake at 500 ° C for 2 hours. After cooling, further vacuum equal volume impregnation in 20mL aqueous solution containing 0.08g chloroplatinic acid, after drying, roast at 500°C for 2 hours, and then wash with water at 500°C in a water vapor-air mixture with a water vapor content of 10%. 8h. After reduction at 490°C for 2 hours in a hydrogen atmosphere, a long-chain alkane dehydrogenation catalyst with a component content of 0.3% of Pt, 2.0% of Ni, 1.0% of Fe and 0.75% of K was obtained, designated as Cat-2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com