A transmission shaft heat-insulated power transfer device for an electric vehicle

A technology for power transfer and electric vehicles, which is applied to transmission parts, control devices, vehicle components, etc., and can solve problems such as poor heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

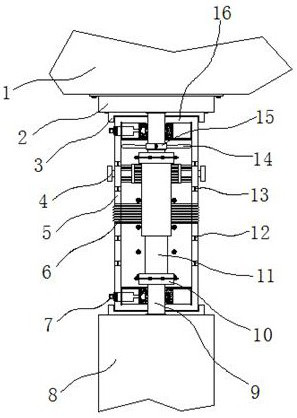

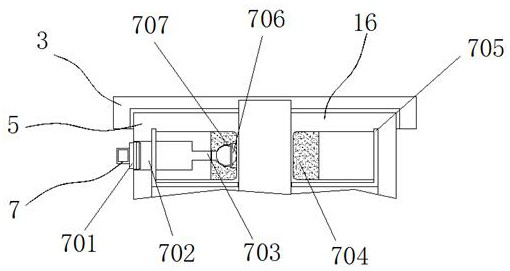

[0035] Example 1: See Figure 1-6 , a transmission shaft heat-insulated power conversion device for electric vehicles, including an engine 1, a left casing 5, a generator 8 and a right casing 16, the bottom end of the engine 1 is provided with a generator 8, and the bottom of the engine 1 The model can be 6105, the model of generator 8 can be EM390, the bottom end of engine 1 is fixedly connected with flywheel group 2, the bottom end of flywheel group 2 and the top of generator 8 are respectively fixedly connected with movable groove 3, and movable groove 3 One side between the inside is provided with a left housing 5, the other side between the inside of the movable groove 3 is provided with a right housing 16, and the two ends between the right housing 16 and one side of the left housing 5 are respectively provided with three The group engaging structure 17, the output ends of the engine 1 and the generator 8 are respectively fixedly connected with an output rod 9, and a tra...

Embodiment 2

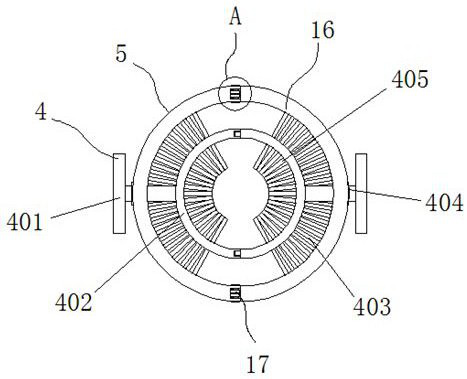

[0040] Embodiment 2: The cleaning structure 4 is composed of a pull rod 401, a fixed rod 402, a first hair brush 403, a chute 404 and a second hair brush 405, and the chute 404 is respectively arranged on the side of the left housing 5 and the right housing 16 Inside, the inside of the chute 404 is provided with a pull rod 401, and one side of the pull rod 401 is fixedly connected with a fixed rod 402, one side of the fixed rod 402 is fixedly connected with a first brush 403, and the other side of the fixed rod 402 is fixedly connected with a Second hair brush 405;

[0041] The first hairbrush 403 and the second hairbrush 405 are in the same horizontal plane;

[0042] Specifically, such as figure 1 and figure 2 As shown, when the splicing of the left housing 5 and the right housing 16 is completed, the pull rod 401 is also spliced and fixed with the fixing rod 402. After that, hold the pull rod 401 with both hands, and lift it up and down along the direction of the chute ...

Embodiment 3

[0043] Embodiment 3: Bellows 6 are respectively provided at the middle positions of the left housing 5 and the right housing 16;

[0044] Specifically, such as figure 1 and Figure 4 As shown, when the length of the transmission shaft 11 is stretched or shortened according to the installation needs of the electric vehicle, the top or bottom end of the left housing 5 and the right housing 16 can be held and pulled in this direction to achieve The extension and compression of the device are adapted to drive shafts 11 of different lengths.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com