Roller fair lead with mooring rope maintenance function

A technology of fairleads and rollers, which is applied to ships and other directions, can solve problems such as affecting engineering operations, insufficient protection, wear and tear of cables and fairleads, and achieve the effects of improving resource utilization, prolonging service life, and reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

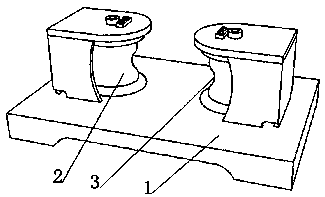

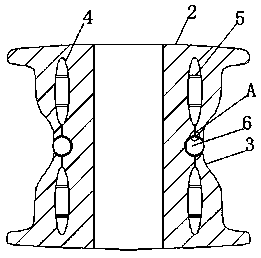

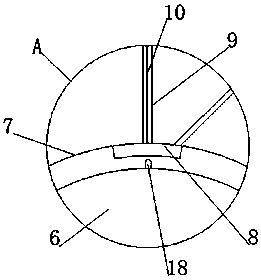

[0043] see Figure 1-2 , a roller fairlead with cable maintenance function, comprising a fairlead body 1, the inner end of the fairlead body 1 is rotatably connected with a roller 2, the outer end of the roller 2 is dug with an arc-shaped ring groove 3, and the arc-shaped ring groove 3 The side wall is excavated with a plurality of evenly distributed spherical grooves 7, the inner ends of the spherical grooves 7 are rotatably connected with drainage rolling balls 6, and the upper and lower ends of the drainage rolling balls 6 are fixedly connected with cylindrical fine protrusions 18. When the cable is squeezed, it will extend up and down.

[0044] see Figure 2-3 , the top and bottom of the spherical groove 7 are dug with oil guide holes 9, the inner end of the roller 2 is dug with two annular cavities 4, the inner ends of the two annular cavities 4 are filled with lubricating oil, and the inner ends of the annular cavities 4 are fixedly connected with A plurality of elasti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com