Joint fixed-point self-maintenance type robot

A robot and joint technology, applied in the field of robots, can solve the problems of uneven force, wear at joints, and heavy workload of staff, and achieve the effect of improving stability and reducing wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

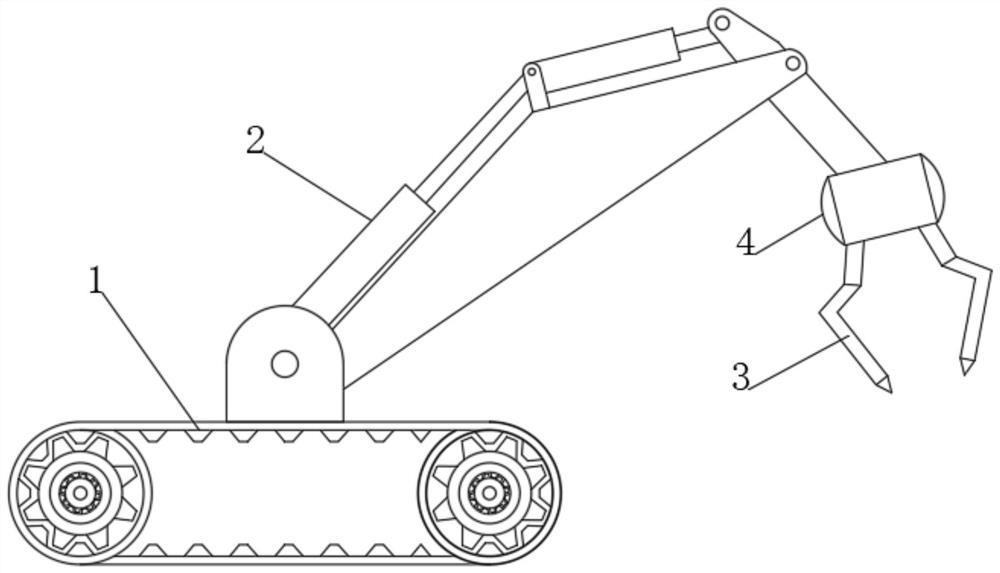

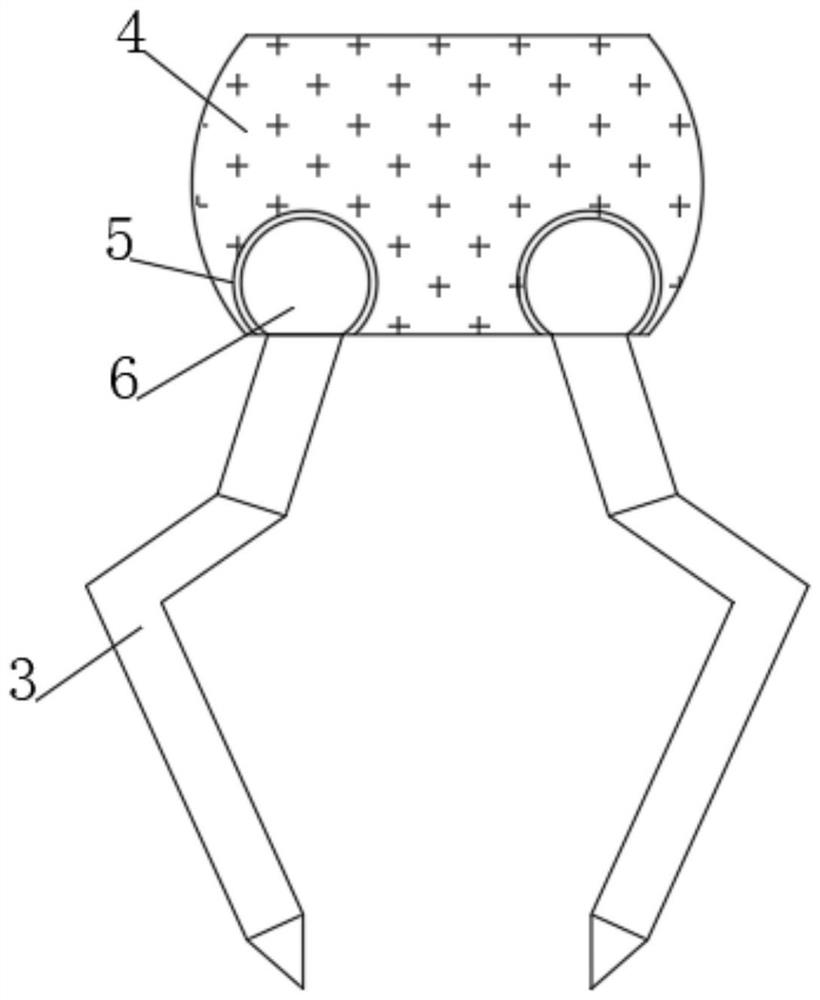

[0043] see Figure 1-2 , a fixed-point self-maintenance robot at joints, including a base 1, a mechanical arm 2 is installed on the upper end of the base 1, a connecting shaft 4 is installed on the end of the The upper end of the claw 3 is fixedly connected with a joint ball 6 , and the lower end of the connecting shaft 4 is dug with a plurality of joint grooves 5 matching the joint ball 6 .

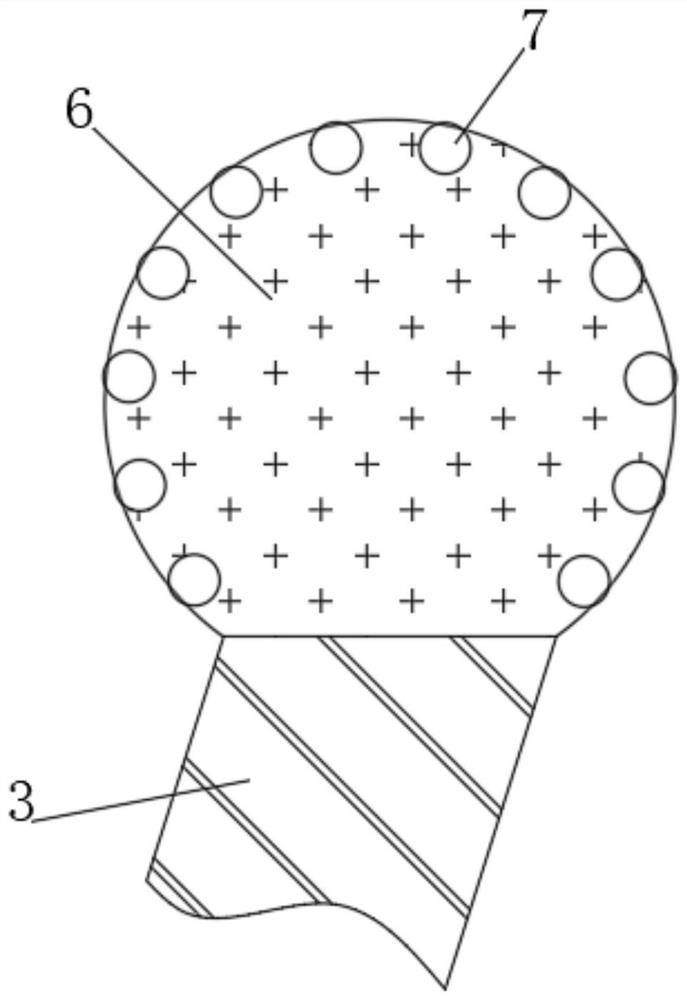

[0044] see Figure 3-5 A central oil storage cavity 102 is excavated in the middle of the joint ball 6, and an air-supported ball is arranged in the middle of the central oil storage cavity 102. The surface of the joint ball 6 is inlaid with a plurality of evenly distributed self-curing ball points 7, and the self-curing ball points 7 include embedded layer 72 and the oil outlet layer 71 connected to the end of the inner inner layer 72, there is no force contact between the inner inner layer 72 and the external contact layer 123, and the end of the oil outlet layer 71 extends to the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com