An aerial refueling device with lateral restraint hose

A technology for aerial refueling and hoses, applied in transportation and packaging, aircraft parts, etc., can solve problems such as susceptibility to airflow disturbance, docking failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

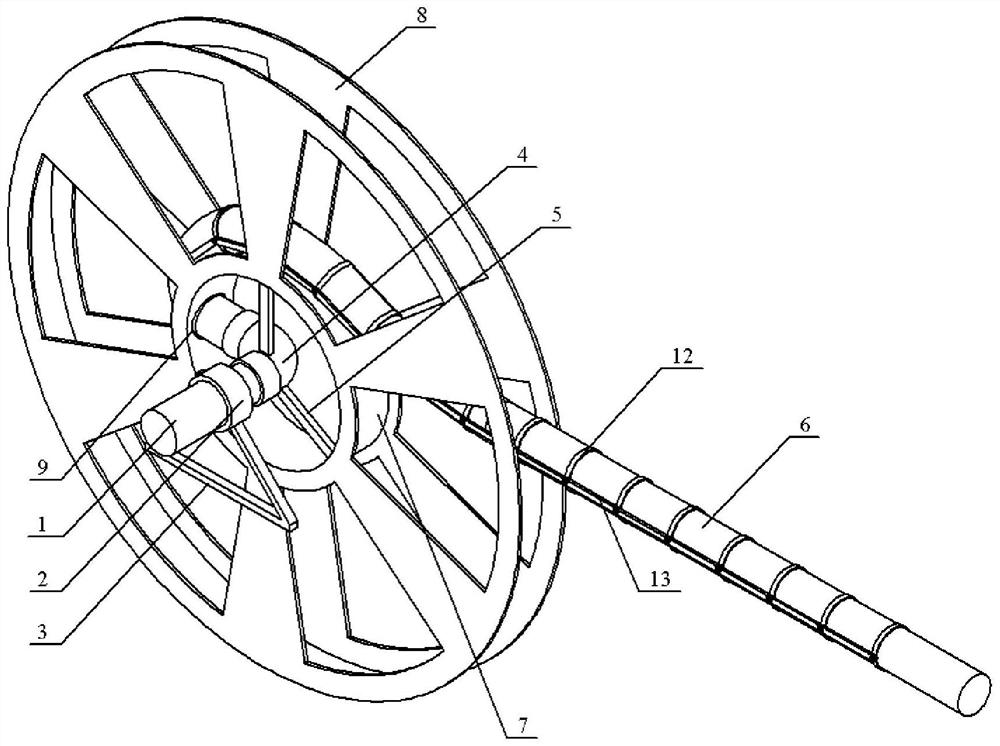

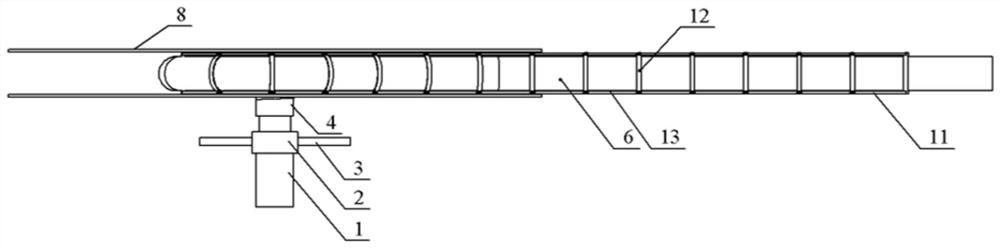

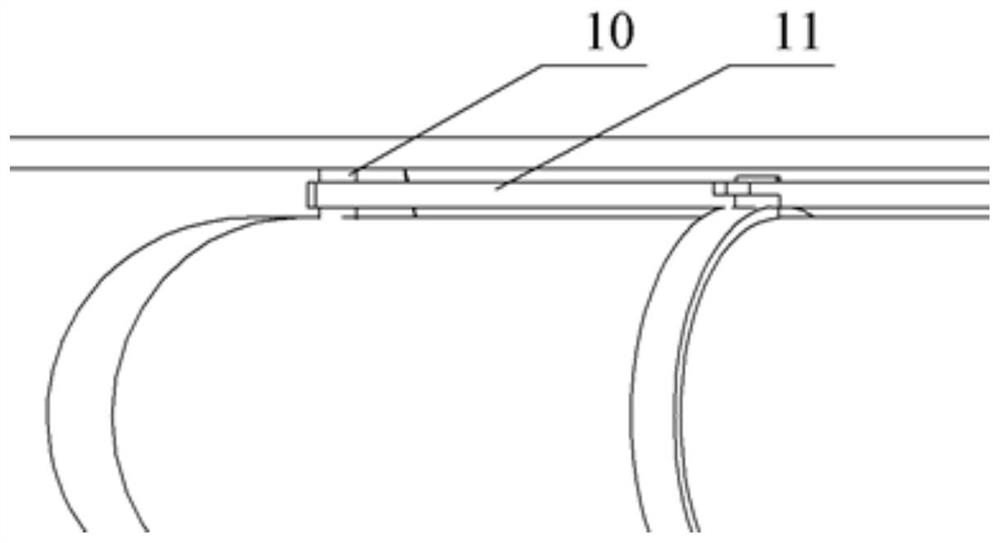

[0027] Embodiment 1: Combining Figure 1 to Figure 8 This embodiment is described. An aerial refueling device with a laterally restrained hose in this embodiment includes an oil pipeline 1, a rotary joint 2, a fixed support 3, a right-angle adapter 4, a support beam 5, a hose 6, and a winch. 7. The side plate 8, the outer frame and the fixing pin 10; the capstan 7 is a cylindrical structure, the outer cylindrical surface of the capstan 7 is provided with a guide hole 9, the capstan 7 is arranged vertically, the number of side plates 8 is two, and the two sides The plate 8 is vertically opposite to the left and right ends of the capstan 7 and is integrally connected with the capstan 7. The side plate 8 is an annular plate-like structure; The number of beams 5 is three, and the three support beams 5 are arranged between the right-angle adapter 4 and the side plate 8 in an annular array. One end of the support beam 5 is fixed to the outer wall of the right-angle adapter 4, and th...

specific Embodiment approach 2

[0028] Specific implementation mode 2: Combining Figure 4 and Figure 5 Illustrating this embodiment, the hose 6 of this embodiment includes an outer elastomer layer 14 and an inner insulator layer 16 , the outer elastomer layer 14 and the inner insulator layer 16 are both circular tubular structures, and the outer elastomer layer 14 is sleeved inside Outside of insulator layer 16 . In this way, the hose 6 is composed of the outer elastomer layer 14 and the inner insulator layer 16 , which can ensure the flexibility of the hose 6 . Other components and connection relationships are the same as in the first embodiment.

specific Embodiment approach 3

[0029] Specific implementation three: combination Figure 4 and Figure 5Describing this embodiment, the hose 6 of this embodiment further includes a steel wire reinforcement layer, which is arranged between the outer elastomer layer 14 and the inner insulator layer 16 , and the steel wire reinforcement layer includes several steel wires 15 , and the steel wires 15 extend along the hose 6 . The length direction wraps outside the inner insulator layer 16 . In this way, arranging the reinforcing layer of steel wire 15 between the outer elastomer layer 14 and the inner insulator layer 16 can increase the tensile stiffness of the hose 6 and reduce the expansion and contraction rate. Other compositions and connection relationships are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com