Liquid crystal composition, liquid crystal display element, and liquid crystal display

A technology of liquid crystal composition and compound, which is applied in the direction of liquid crystal materials, instruments, chemical instruments and methods, etc., which can solve the problems of display afterimage display quality, etc., achieve high voltage retention rate and improve product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

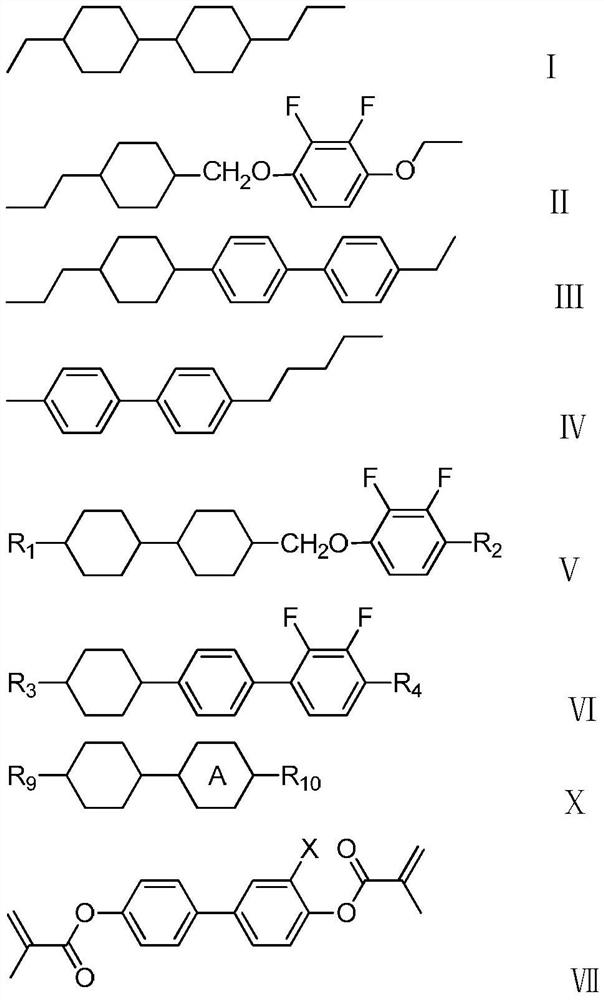

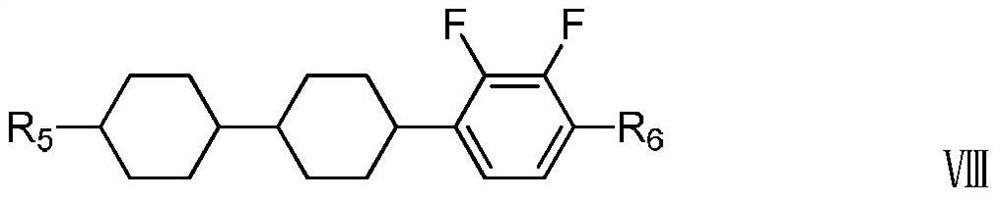

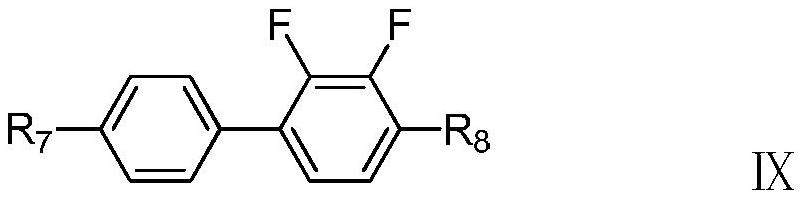

Method used

Image

Examples

preparation example Construction

[0096] As the preparation method of the liquid crystal display of the present invention, those skilled in the art can select an appropriate method for preparation according to common knowledge in the field. As an example of the preparation method of the liquid crystal display of the present invention, for example, the preparation method comprising the following steps:

[0097] Coating an alignment material evenly on the surface of the first substrate and the second substrate. The alignment material can be polyimide, and the evenly coated alignment material is heated and cured at a heating temperature of 210-250°C to form an alignment layer;

[0098] Scatter spacers on the surface of the second substrate, apply frame glue along the edge of the first substrate, and cure at 100°C to 150°C;

[0099] arranging the first substrate and the second substrate oppositely, and bonding them together to form a structure with a sandwich space;

[0100] The liquid crystal composition is inje...

Embodiment 1

[0133] The formula and corresponding properties of the liquid crystal composition are shown in Table 3 below.

[0134] Table 3 The formula and corresponding performance of the liquid crystal composition of embodiment 1

[0135]

[0136]

Embodiment 2

[0143] The formula and corresponding properties of the liquid crystal composition are shown in Table 5 below.

[0144] Formulation and corresponding performance of the liquid crystal composition of table 5 embodiment 2

[0145]

[0146]

PUM

| Property | Measurement | Unit |

|---|---|---|

| isotropization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com