A frame structure exterior wall waterproof type aac thermal insulation laminated wall panel structure

A frame structure and exterior wall panel technology, applied in thermal insulation, building structure, building thermal insulation materials, etc., can solve the lack of laminated wall panel fixing and anti-seismic anchoring methods, the inability to achieve energy saving requirements, and the inability to eliminate thermal bridge phenomena, etc. problem, to achieve the effect of eliminating thermal bridge phenomenon, avoiding long-term water immersion, and facilitating popularization and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

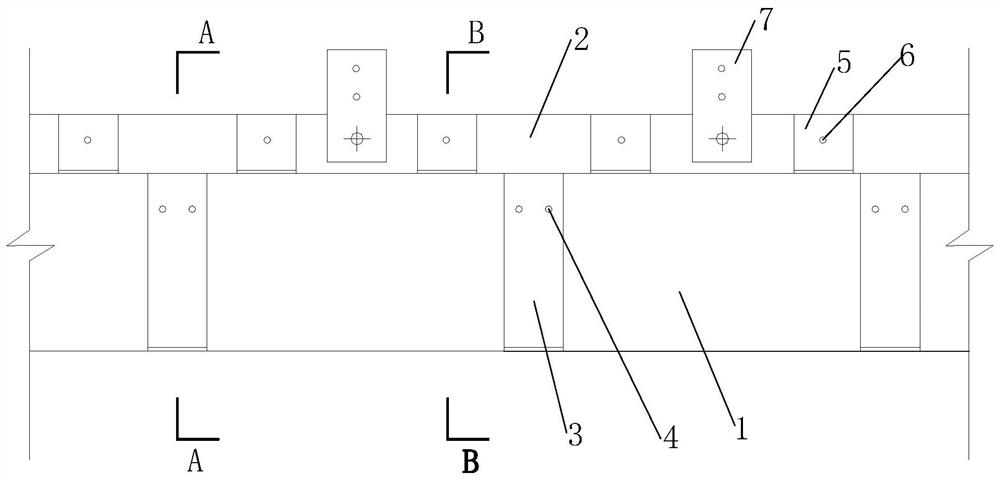

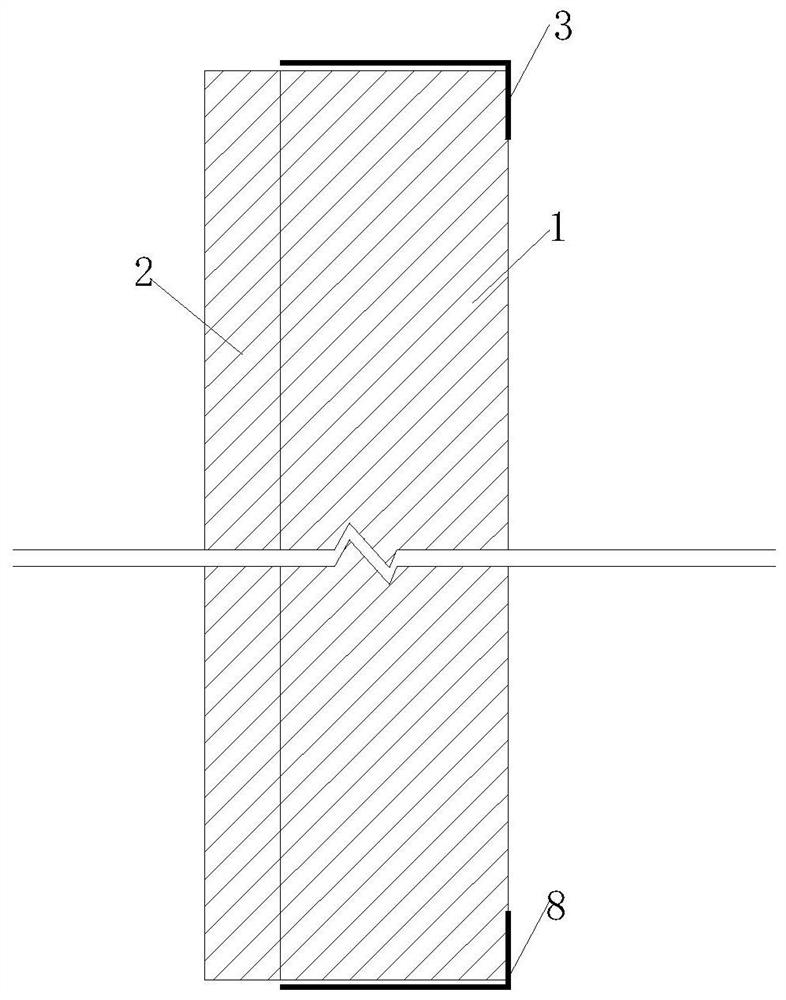

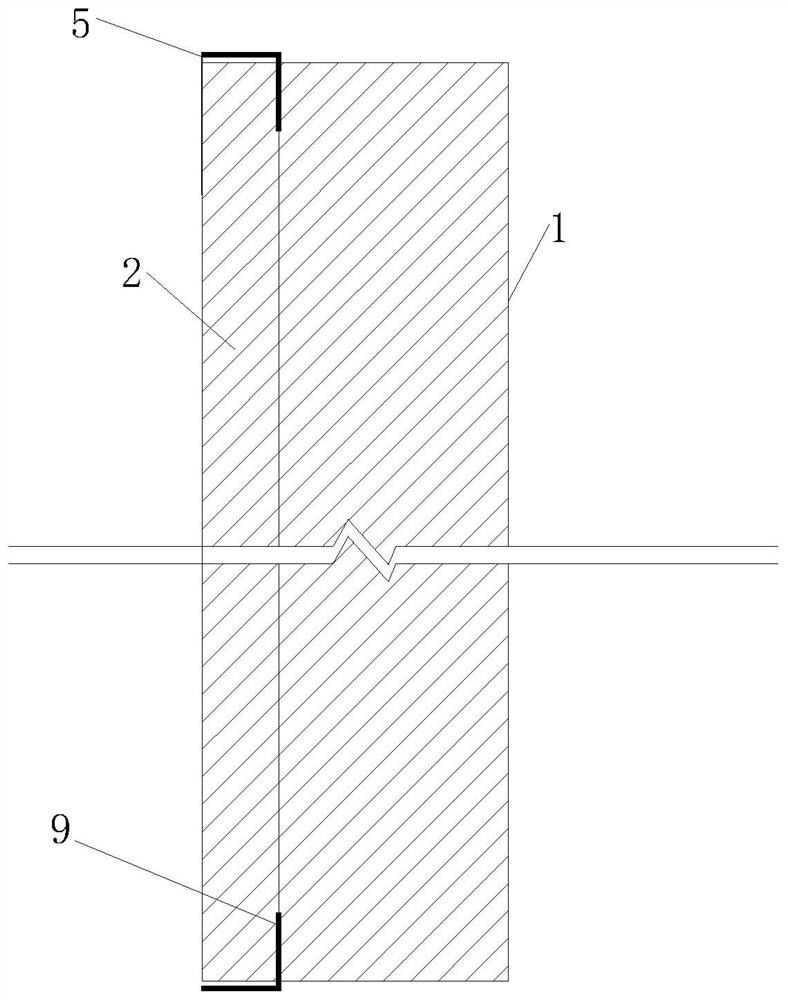

[0036] Such as Figure 1 to Figure 5 As shown, the present invention includes an AAC thermal insulation laminated wall panel arranged between the adjacent first beam plate 14 and the second beam plate 12 in the frame structure, the first beam plate 14 is located at the lower side of the second beam plate 12, and the frame Each beam plate of the structure is equipped with a water retaining platform 17, and the AAC thermal insulation laminated wall panels include the AAC thermal insulation laminated outer wall panel 1 and the AAC thermal insulation laminated inner wall panel 2, and the upper part of the AAC thermal insulation laminated outer wall panel 1 A plurality of upper limit clamps 3 for laminated outer wall panels are arranged along the length direction, and a plurality of upper limit clamps 5 for laminated inner wall panels are arranged on the upper side of the AAC thermal insulation laminated inner wall panel 2 along the length direction. The upper limit fixture 3 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com