Wind power blade support

A technology of wind power blades and support bottoms, applied in the field of wind power, can solve problems such as easy shaking, slipping, damage to blades, and many intermediate processes, and achieve the effect of a firm structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

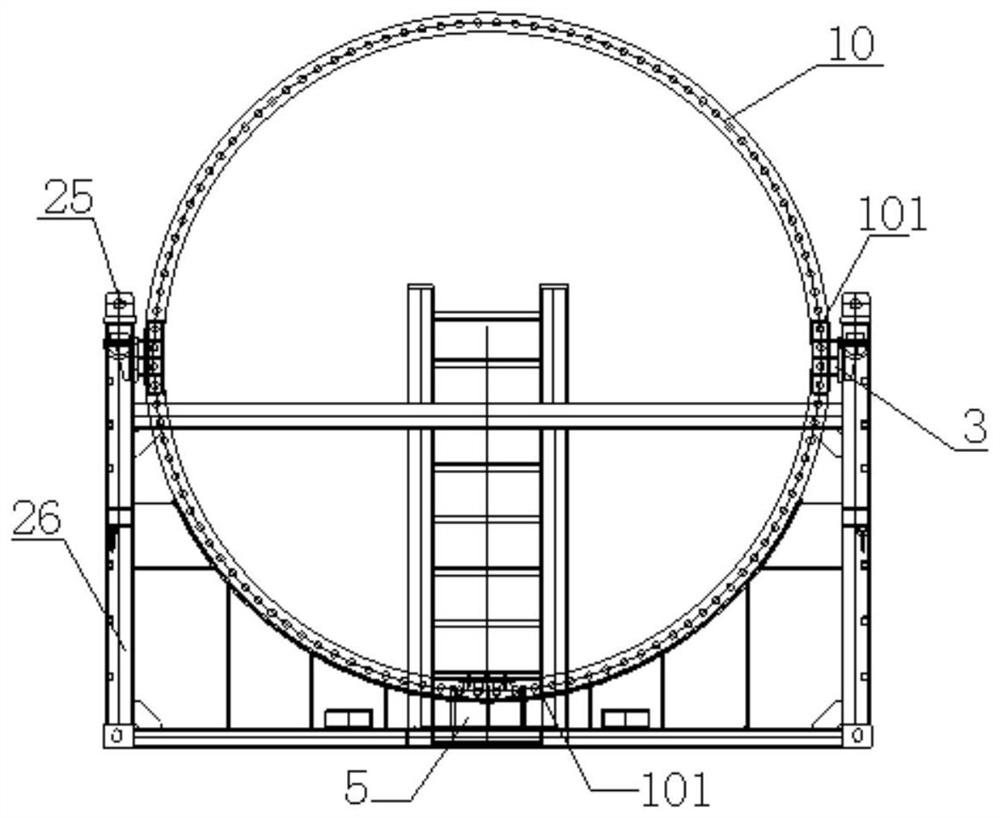

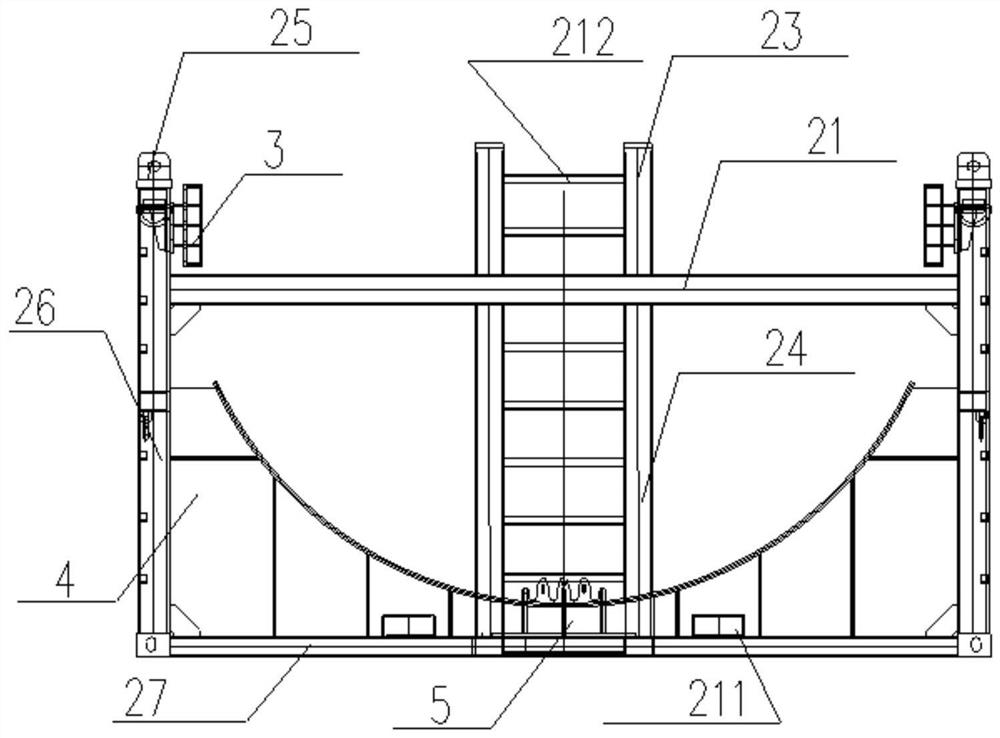

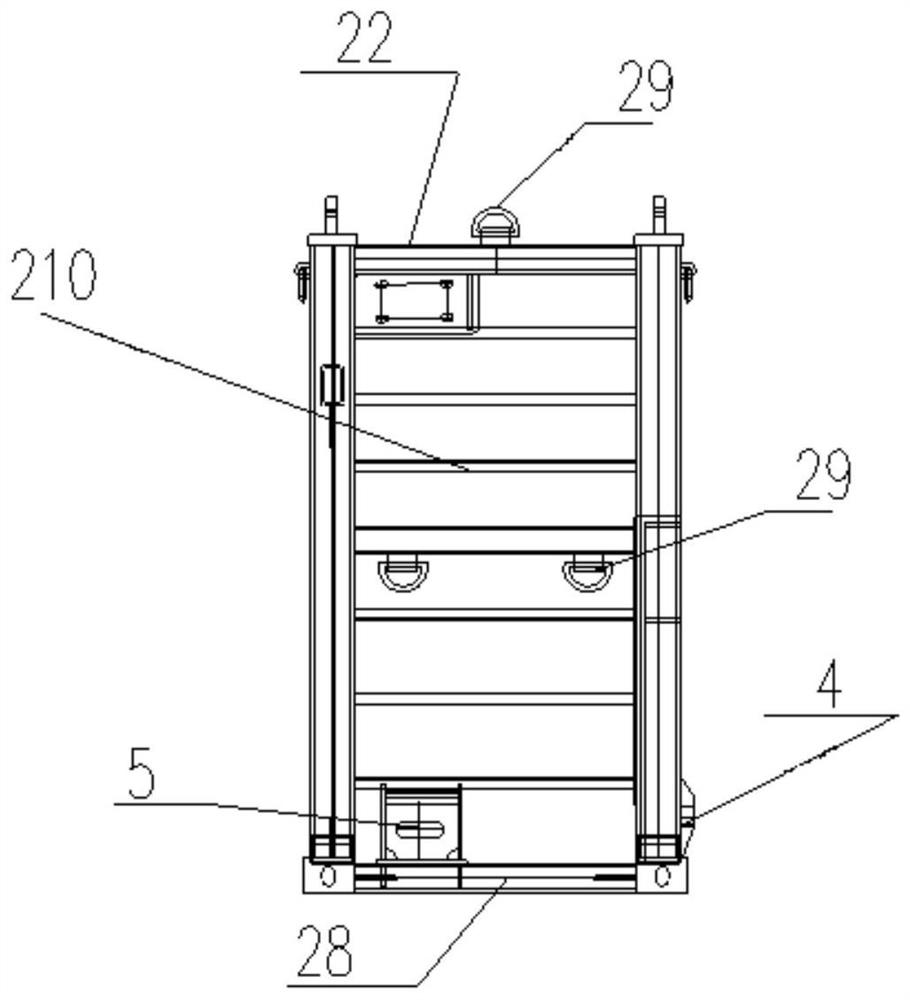

[0022] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings.

[0023] Such as figure 1 , figure 2 with image 3 As shown, the blade root lower bracket 2 includes: lower bracket top longitudinal beam 21, lower bracket top beam 22, first lower bracket middle column 23, second lower bracket middle column 24, lower bracket connecting seat 25, lower bracket side column 26 , lower bracket bottom longitudinal beam 27, lower bracket bottom beam 28, eye ring 29, first straight ladder angle steel 210, lower bracket forklift hole 211 and second straight ladder angle steel 212.

[0024] The blade root lower bracket 2 includes a first support frame and a second support frame arranged front and back, and the structures of the two support frames are the same. The first supporting frame includes two vertically arranged lower support side columns 26 , a lower support bottom longitudinal beam 27 and a lower suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com