Duplex stacked filter

A double filter and filter technology, applied in the direction of fluid pressure actuation device, servo motor assembly, fluid pressure actuation system component, etc., can solve the problem of directional valve, flow valve, pressure control valve, valve stuck valve, hydraulic system filter The protection mechanism is incomplete, and the internal pollutants cannot be effectively purified, so as to achieve the effect of convenient installation and maintenance, avoiding solid foreign matter blocking, and easy cleaning and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below with reference to the accompanying drawings embodiments.

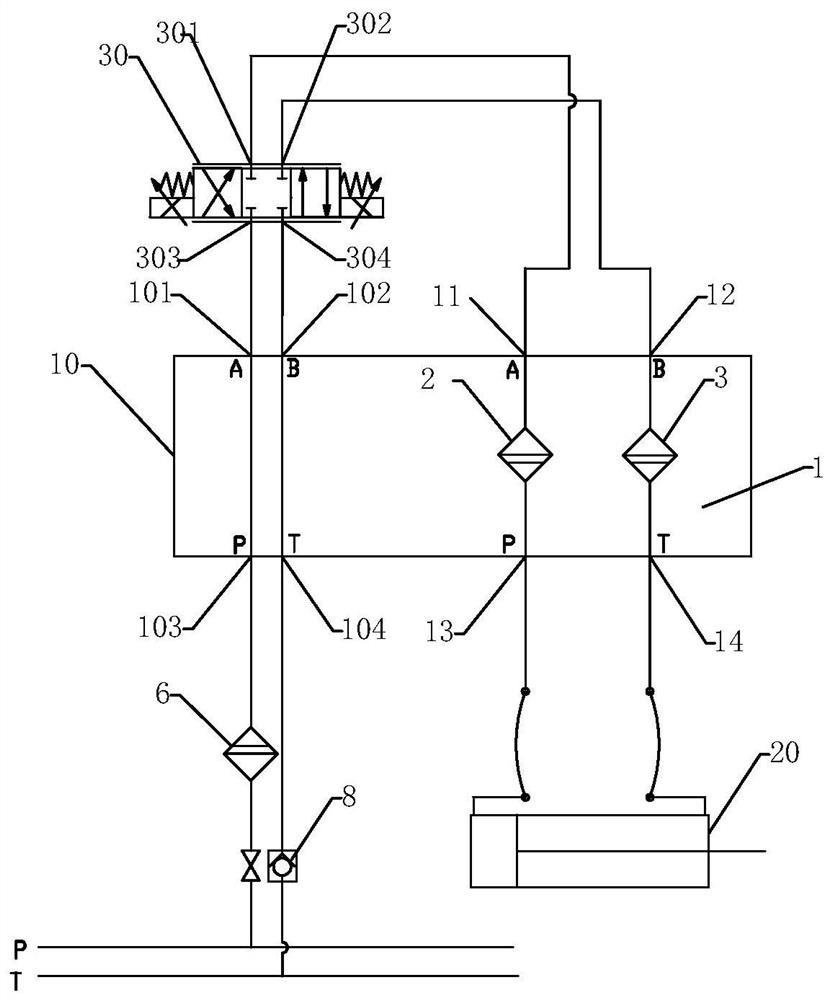

[0024] The invention is taken as an example with the cylinder 20 controlled by the most common proportional direction valve 30, and the present invention is used as an example in the hydraulic circuit as an example, and the application principle is explained.

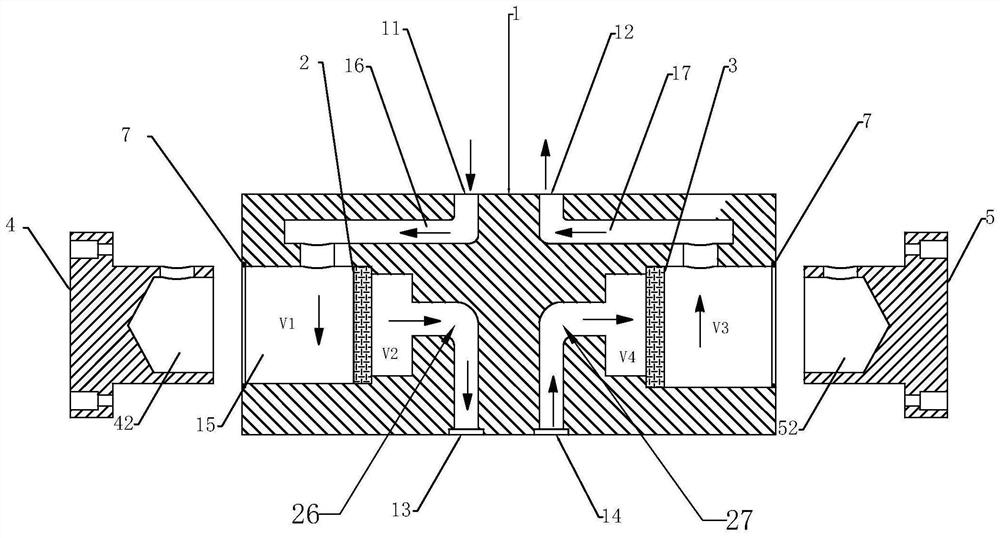

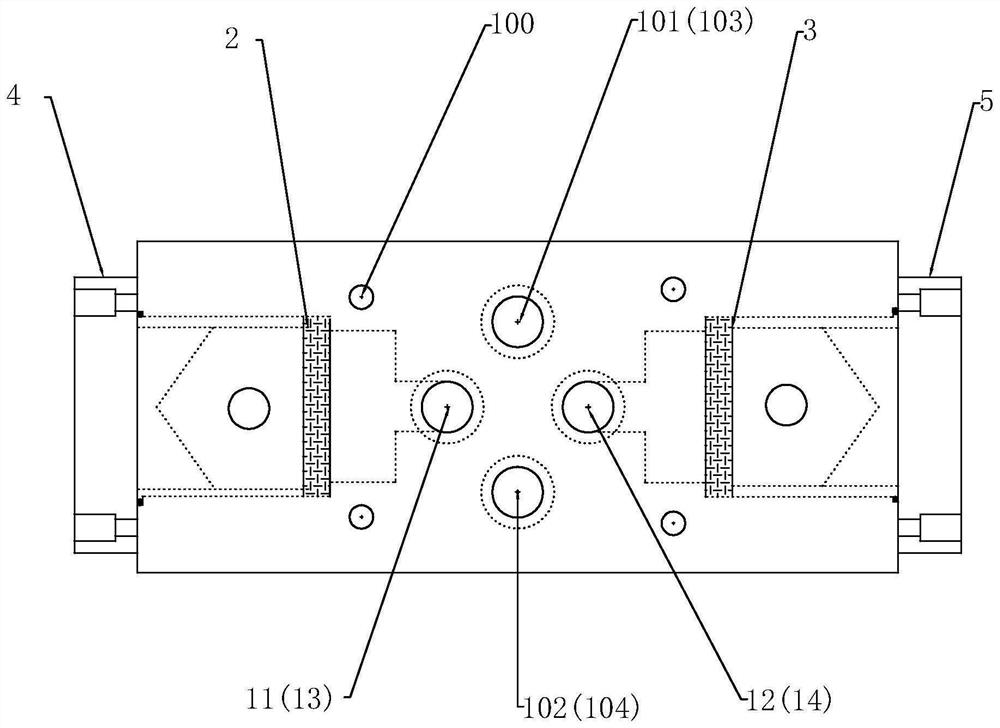

[0025] In the filter structure according to the present invention, the filter structure corresponding to the 6-through-diameter logic control valve is an example, indicating the principle of the internal structure, and has a similar internal structure for 10 pacating diameter, 16-diameter logic control valve, is not difficult. Promote its application.

[0026] Such as Figure 1 ~ 6 As shown, a two-laminate filter includes a piece of valve block 1, two sets of filter cartridges 2 and 3 and two valve sleeves 4 and 5; the filter is superimposed in a valve block 1. The primary layer is mounted on the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Circle radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com