Conveniently used mechanical sealing element

A technology for mechanical seals and plastic parts, which is applied in the direction of mechanical equipment, passing components, pipes/pipe joints/pipe fittings, etc., which can solve the problems of difficult installation and disassembly of pipe seals, and achieve simple structure, convenient use, and good sealing effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

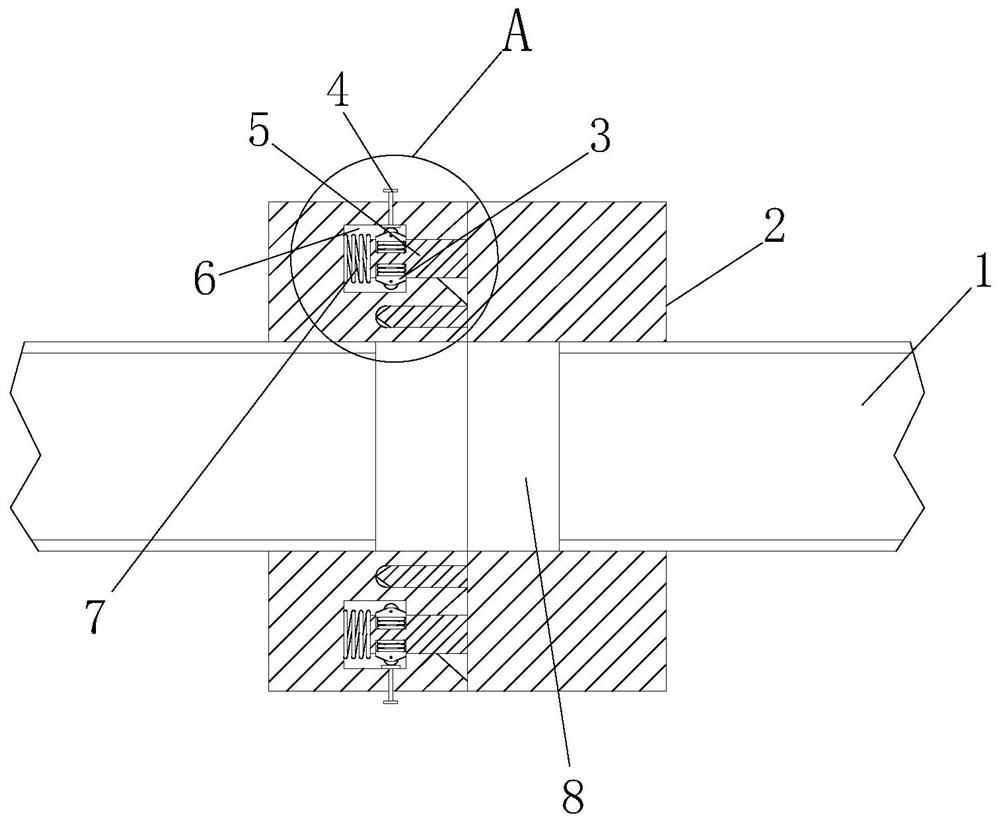

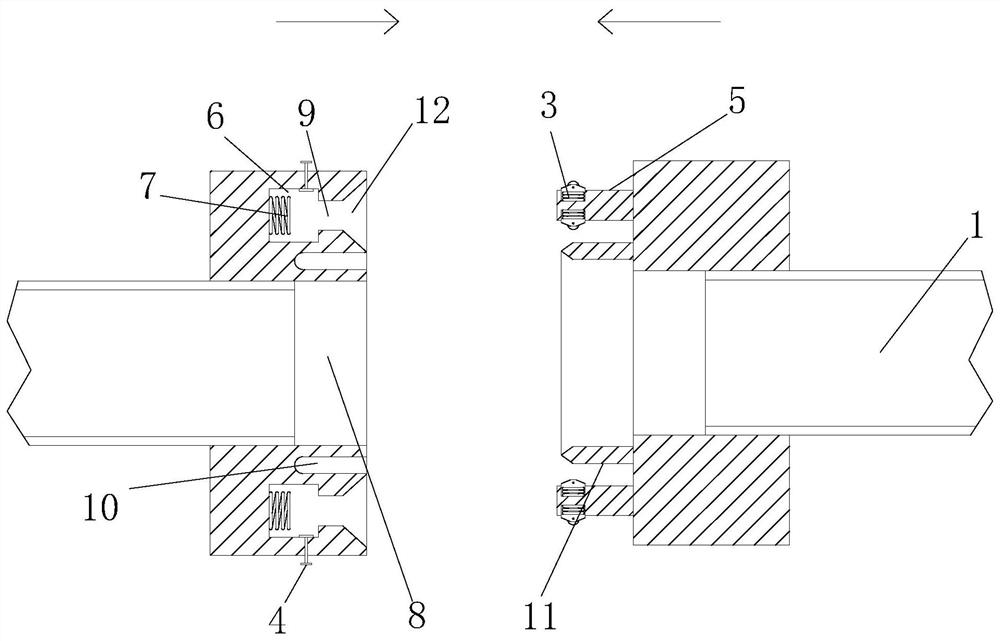

[0020] see Figure 1-3 , the present invention provides an easy-to-use mechanical seal, which includes a pipe 1 and two attached discs 2, and the two discs 2 are provided with threads that run through the two ends of the disc 2 and are screwed with the pipe 1 respectively. Hole 8, the opposite side on one of the discs 2 is fixedly installed with a ring-shaped plastic part 11, and the other disc 2 is provided with a circular card slot 10 that is compatible with the ring-shaped plastic part 11, and the two discs 2 A latch 5 is fixedly installed on the opposite side of one, and a slot 9 compatible with the latch 5 is provided on the other disk 2, and the bottom of the slot 9 communicates with a rectangular slot 6, and the diameter of the rectangular slot 6 is larger than The diameter of the slot 9, the bolt 5 is provided with an elastic expansion member 3 that is compatible with the rectangular slot 6, and the disc 2 is provided with a reset mechanism that resets the elastic expa...

Embodiment 2

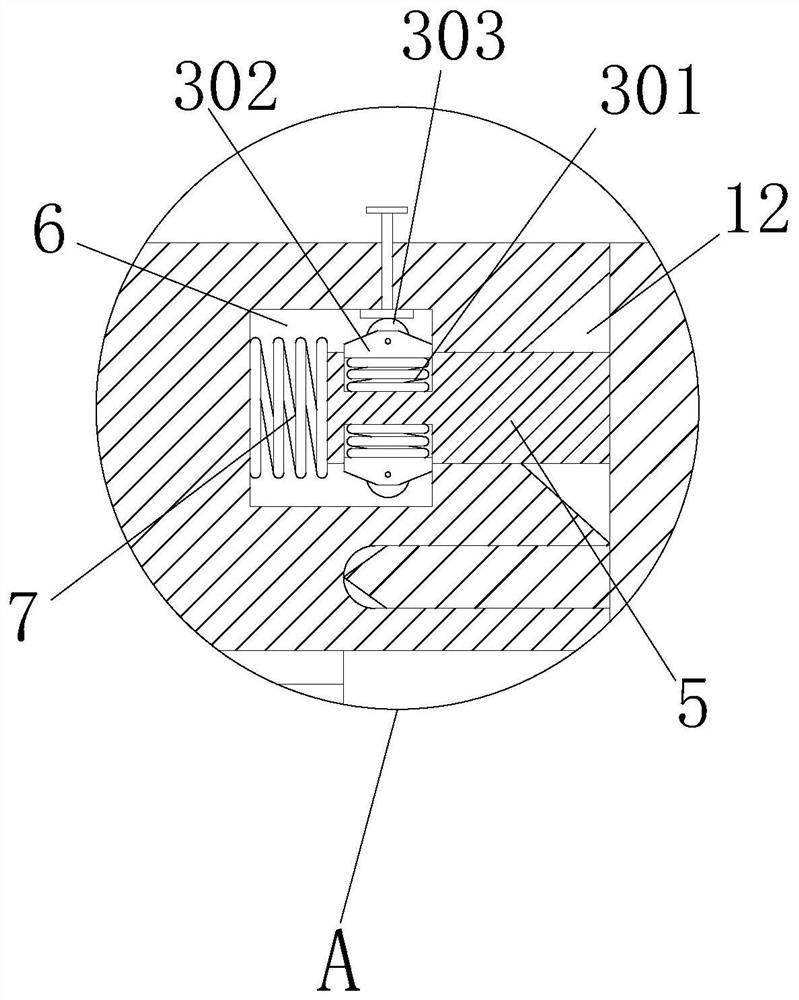

[0023] see Figure 1-3 , the present embodiment is further optimized on the basis of embodiment 1, specifically, the disk 2 that has the slot 9 is located on the opposite side and has a chute 12, and the bottom of the chute 12 is in contact with the slot 9. Connected, the elastic expansion part 3 includes a spring groove provided on the latch 5, the bottom of the spring groove is fixedly equipped with a second spring 301, and the top of the second spring 301 is fixedly installed with a limit block 302, and the limit block 302 is far away from the second spring. One side of 301 is hinged with roller 303 .

[0024] In this embodiment, the bottom of the inner wall of the rectangular slot 6 is fixed with the first spring 7 , and both sides of the limit block 302 on the roller 303 are set as slopes.

[0025] The reset mechanism includes a through hole provided on the disk 2 and positioned on one side of the elastic expansion member 3, and a push rod 4 is inserted through the throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com