Smelting furnace feeding device capable of removing dust

A technology of feeding device and furnace, applied in descaling devices, furnaces, removing smoke and dust, etc., can solve the problems of easy generation of debris such as dust and gravel, affecting the smelting process, and wear of feeding device, etc., to achieve enhanced rotational stability, The effect of high smelting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings.

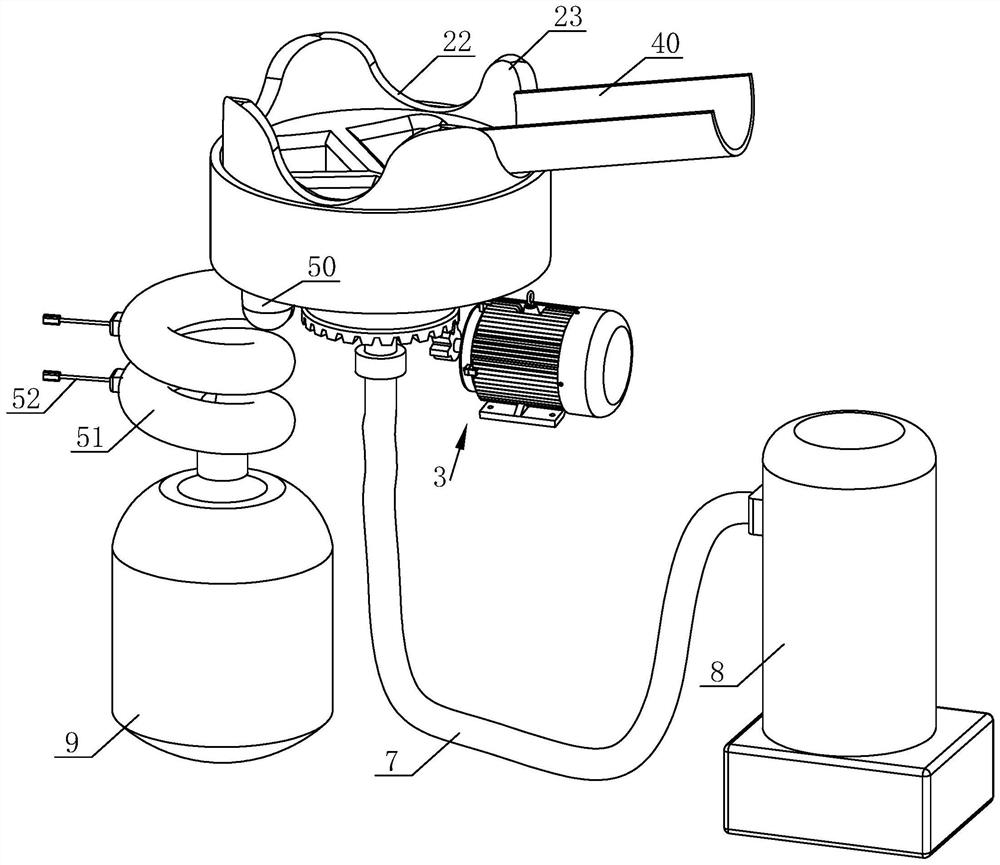

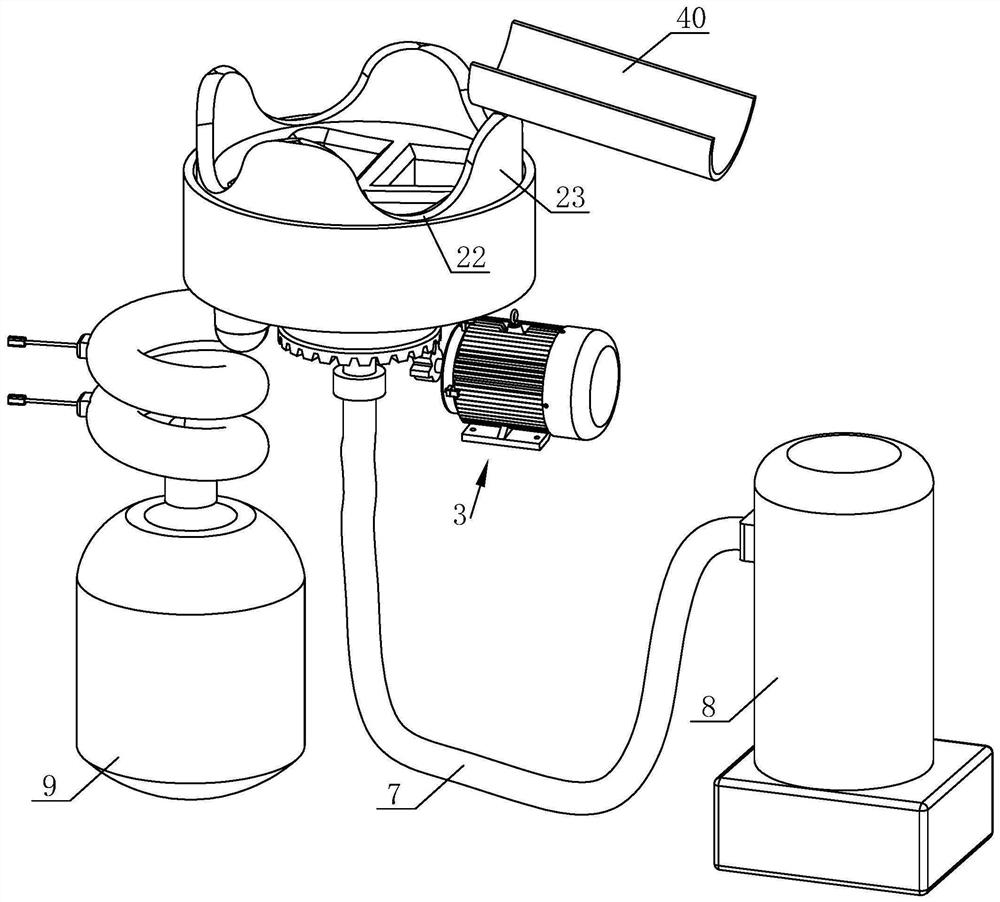

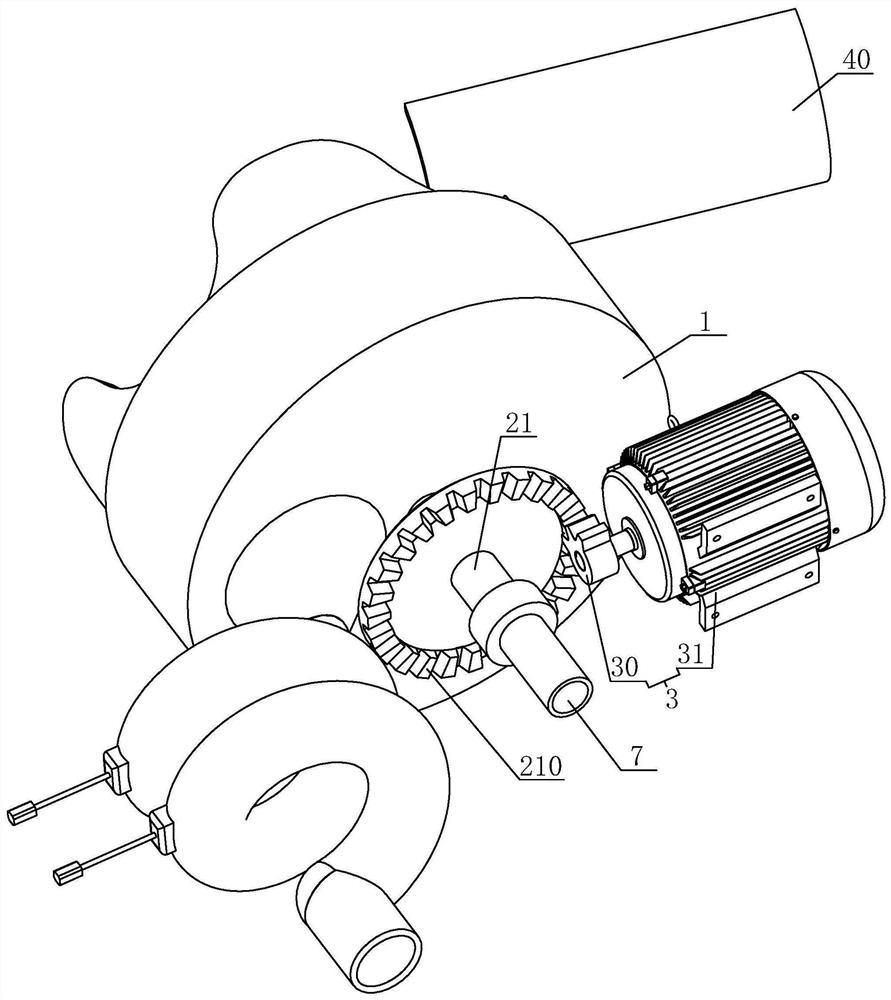

[0038] Such as Figure 6 to Figure 9 The shown furnace feeding device that can remove dust includes a material distribution mechanism and a dust removal mechanism. The dust mechanism includes thirty-two dust suction ports 6 , a dust removal channel 7 and a vacuum cleaner 8 .

[0039] Such as Figure 4 to Figure 6 As shown, the rotating distributing part 2 is a cylindrical structure, and the rotating distributing part 2 is equipped with four transport bins 20 in a circular equidistant manner. The radii of the material parts 2 coincide, and the transport bin 20 runs through the upper and lower ends of the rotating material part 2 .

[0040] The distribution bottom plate 1 is circular, and the radius of the bottom plate is 2cm larger than the radius of the rotating distribution part 2. The distribution bottom plate 1 is provided with an outlet 10 for discharging, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com